Quick levelling and mounting device for embedded parts

An installation device and fast technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of low construction accuracy and low efficiency, improve the installation quality and installation efficiency of embedded parts, and reduce skill requirements. , the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further describe the fast leveling installation device for embedded parts of the present invention, it will be further described in detail below in conjunction with the accompanying drawings.

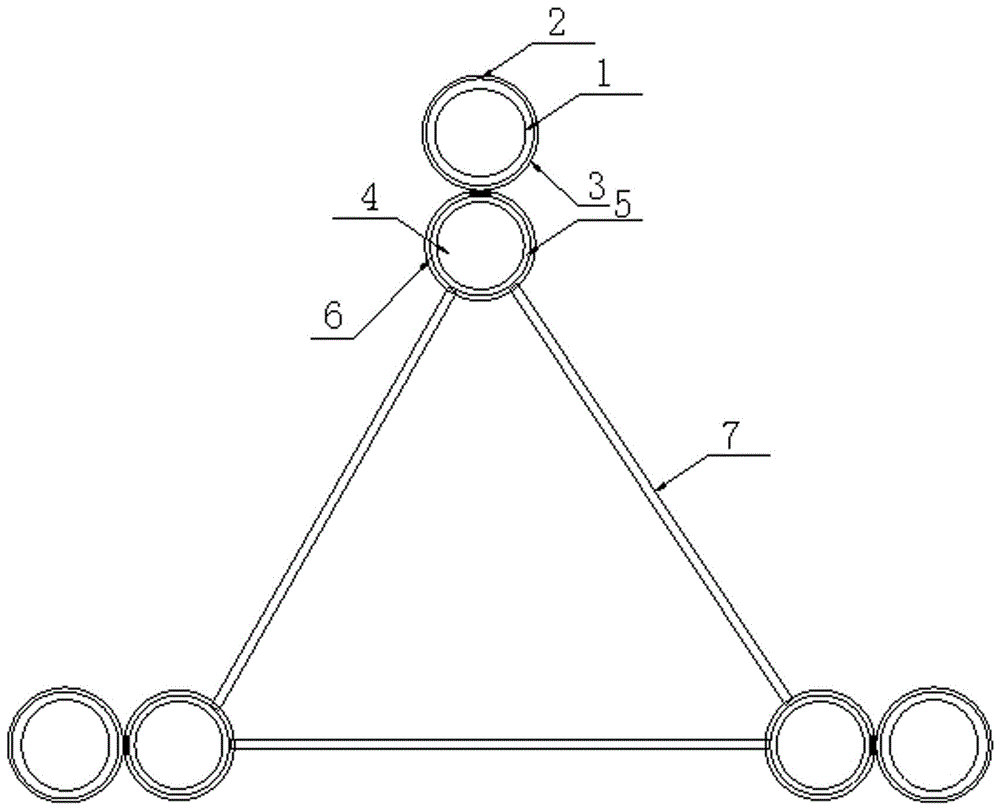

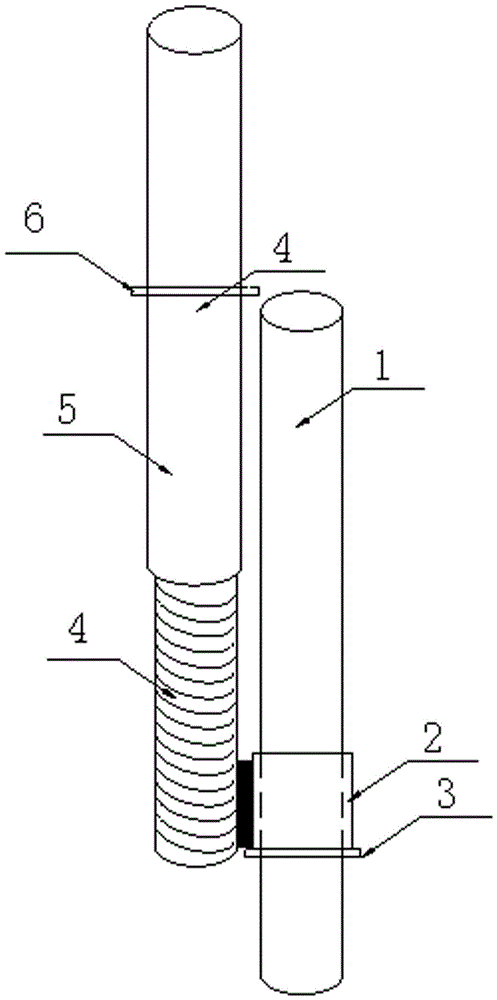

[0012] figure 1 with 2 It shows a fast leveling installation device for embedded parts, including three leveling mechanisms arranged in a triangle for supporting the support rod 7, and the leveling mechanism is fixed by the support fixing pipe 1, the adjustment loop 2, the The base 3, the screw rod 4, the elevation and level adjustment sleeve 5, and the horizontal support ring 6 are composed; the fixed base 3 is fixed on the support fixed pipe 1; The upper part, and can rotate freely along the support fixed pipe 1; the side of the adjustable looper 2 is fixedly connected with the screw rod 4, and the elevation and level adjustment sleeve 5 is set on the screw rod 4 through the screw thread placed on its inner wall. The horizontal support ring 6 supporting the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com