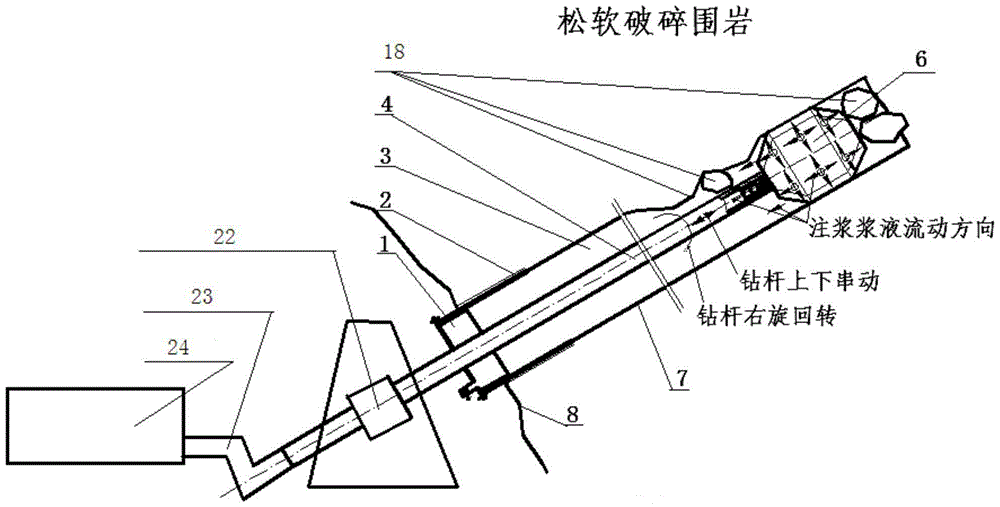

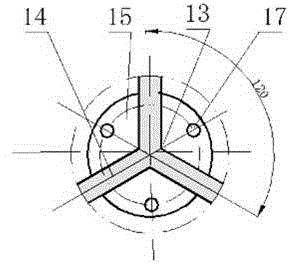

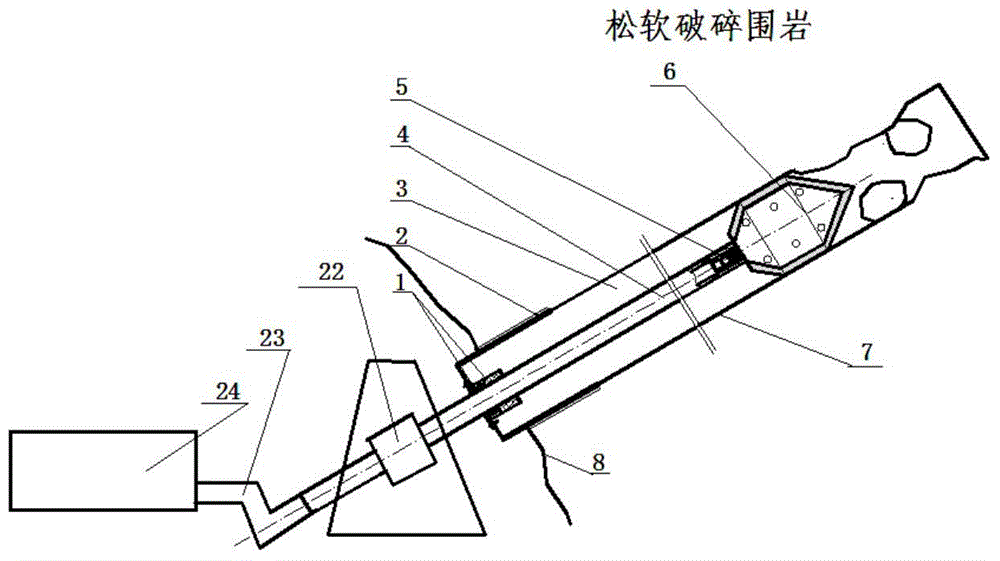

Collapse-prevention two-way rib wing jetting grouting drill bit and using method thereof

A jet grouting and anti-collapse technology, applied in drill bits, earth-moving drilling, drilling equipment, etc., can solve problems such as difficulty in eliminating hole wall shrinkage or collapse and falling blocks, short solidification time of rapid-setting slurry, and high safety risks. Achieve the effect of shortening the waiting time and improving the effect of spray reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] A coal mine in Heze, Shandong Province is a mine with extremely complex hydrogeological conditions. Concentrated and scattered water gushing occurs on the roof of the mine's total return air uphill roadway, with a large water gushing area and a total water gushing volume of 25m 3 About / h, the inflow water source is fine sandstone (M5), and the normal water pressure of the aquifer in the treatment area is 3.5MPa. During the construction of the M5 grouting and water blocking drilling, due to the loose and broken shallow surrounding rock, the wall of the borehole collapsed seriously, and drilling accidents occurred frequently. The cement slurry is used for the slurry, and the cement slurry consolidation time is 72 hours according to the design, and the waiting time is long. Seriously affected the progress of the project. The subsequent research and application of the non-lifting anti-collapse bidirectional rib jet grouting drill bit has achieved a successful one-time gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com