Fan blade of cooling fan

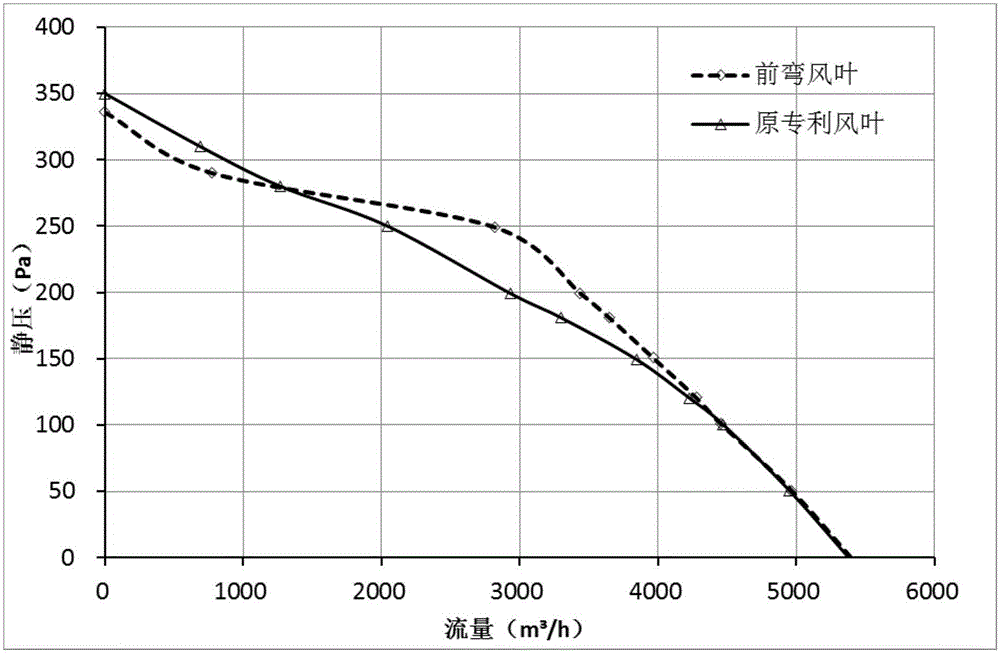

A technology for cooling fans and fan blades, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., to achieve obvious advantages in noise performance, small losses, and improved flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

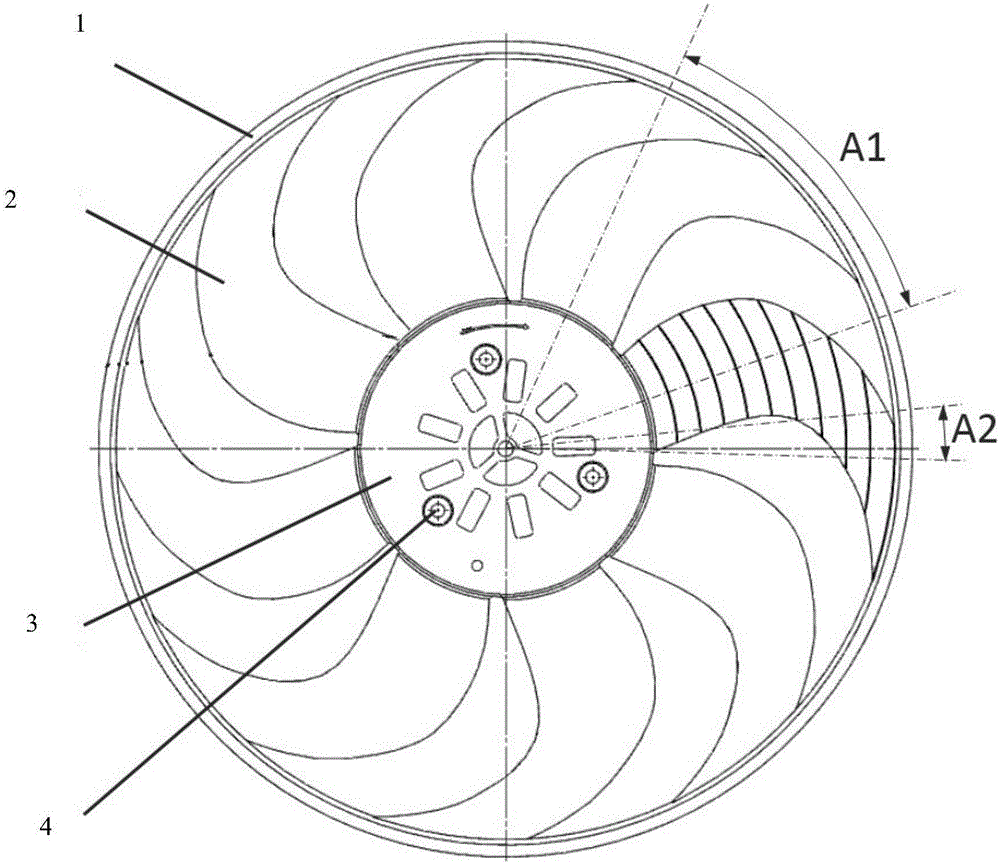

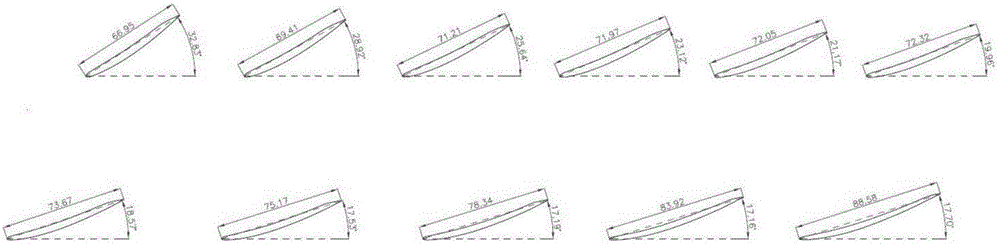

[0023] according to figure 1 , figure 2 The wind blade of a cooling fan shown is composed of a hub 3 and a blade 2 wind protection ring 1. The wind blade is an integral injection molded product. 3 are connected, and the coupling structure 4 is arranged on the hub 3. The motor shaft is connected to the fan blade through the coupling structure 4 to drive the fan blade to rotate and transport air. The blades in the present invention are 8 equidistant distributions, and the distribution angles are 45°, as figure 1 Shown in A1. Among them, the blade adopts a forward-curved type, and 11 cross-sections are designed equidistantly from the inner diameter to the outer diameter. 8.1°, -6.6°, -3°, 2.6°, 9.4°, 19.2°, such as figure 1 Shown in A2. In order to obtain stable flow and operate at the highest static pressure efficiency under specified wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com