Auxiliary ammonia exhausting device of ammonia-mixed diesel generator

A technology of diesel generator and starter motor, applied in engine components, engine control, combustion engine, etc., can solve the problems of residual ammonia gas in cylinders, corrode the engine, affect the service life, etc., to improve aerodynamic performance, easy maintenance, and reduce corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

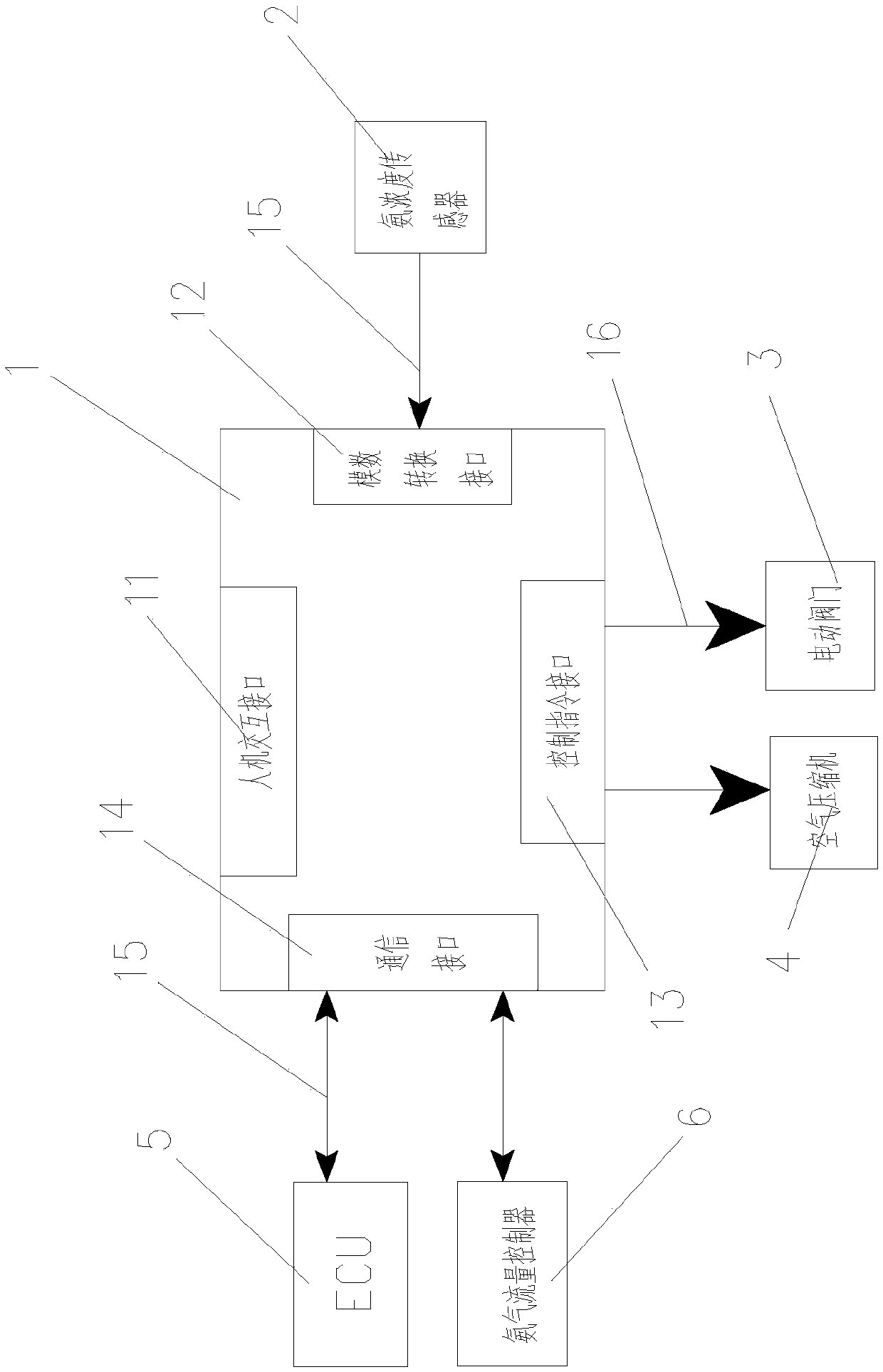

[0019] Please check figure 1 , an auxiliary ammonia discharge device for a mixed ammonia diesel generator, including a starter motor (not shown in the figure), a controller 1, an ammonia concentration sensor 2, an electric valve 3, an air compressor 4, an ECU (diesel generator control device) 5 and ammonia flow controller 6.

[0020] The starter motor is equipped with a crankshaft, and the crankshaft of the starter motor is connected with the air compressor 4 to drive the air compressor 4 to rotate. In this embodiment, the air compressor 4 is connected with the crankshaft of the starter motor through a belt. Use the starter motor of the diesel generator to rotate to drive the air compressor to inject air into the cylinder, and take away the remaining ammonia fuel in the cylinder, reduce the corrosion of ammonia to the diesel generator, improve the aerodynamic performance of the diesel generator, low cost, and no need Additional power supply equipment, light and reliable, eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com