Separation type airflow drying kettle

An airflow drying and separation technology, applied in the direction of non-progressive dryers, drying solid materials, drying gas arrangement, etc., can solve the problems of reduced drying efficiency, inconvenient collection, and troubles for operators, and achieves convenient cleaning and maintenance. Ease of collection and improvement of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

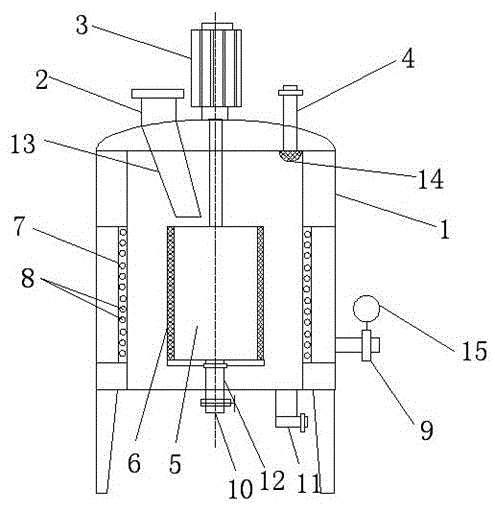

[0014] Embodiment 1: as figure 1 A separate airflow drying kettle is shown, the airflow drying kettle is a cylindrical shell 1, the top of the shell 1 is provided with a feeding port 2 and a transmission motor 3, and the middle part of the shell 1 is provided with a cylindrical Shaped drying cylinder 5, the top of the drying cylinder 5 is provided with a rotating shaft fixedly connected to the transmission motor 3, the side wall of the drying cylinder 5 is composed of a filter screen 6, the housing 1 is connected with the drying cylinder 5 There are two vertical air blast pipelines 7 on the inner wall of the same height, and multiple air outlets 8 are evenly distributed on the different heights of the air blast pipelines 7, and the outer side of the housing 1 is provided with an air intake pipeline 9 is connected to the blast pipeline 7, the bottom of the housing 1 is provided with a light material collection port 11 and a heavy material collection port 10, and the heavy mater...

Embodiment 2

[0015] Embodiment 2: as figure 1 As shown, the light material collection port 11 is arranged at the bottom of the housing 1, and the light material collection port 11 is connected to the vacuum pump through a pipeline; All the materials are discharged from the drying cylinder 5 and enter the shell 1. After the blast pipeline 7 stops working, the small particles floating in the shell 1 gradually deposit on the bottom of the shell 1 and pass through the light material collection port 11. Combined with the vacuum pump, it is convenient for the collection of small particles and light materials.

Embodiment 3

[0016] Embodiment 3: as figure 1 As shown, the bottom of the feeding port 2 is provided with a feed pipe 13 connected to the top of the drying drum 5, and the feed pipe 13 is an inclined feed pipe; through the feed pipe 13, the material is conveniently directly added to the drying drum 5, and the material is in the drying drum 5. The dual action of centrifugal force and airflow enters the drying cylinder 5 to further improve the drying efficiency of materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com