A kind of gas chromatography test method of 4-ethoxyl-2,3-difluorophenol

A technology of difluorophenol and gas chromatography, which is applied in the field of chemical analysis, can solve the problems of material composition analysis, unstable analysis results, inability to accurately guide process production, etc., and achieve fast analysis speed, stable peak value, and cost-saving production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

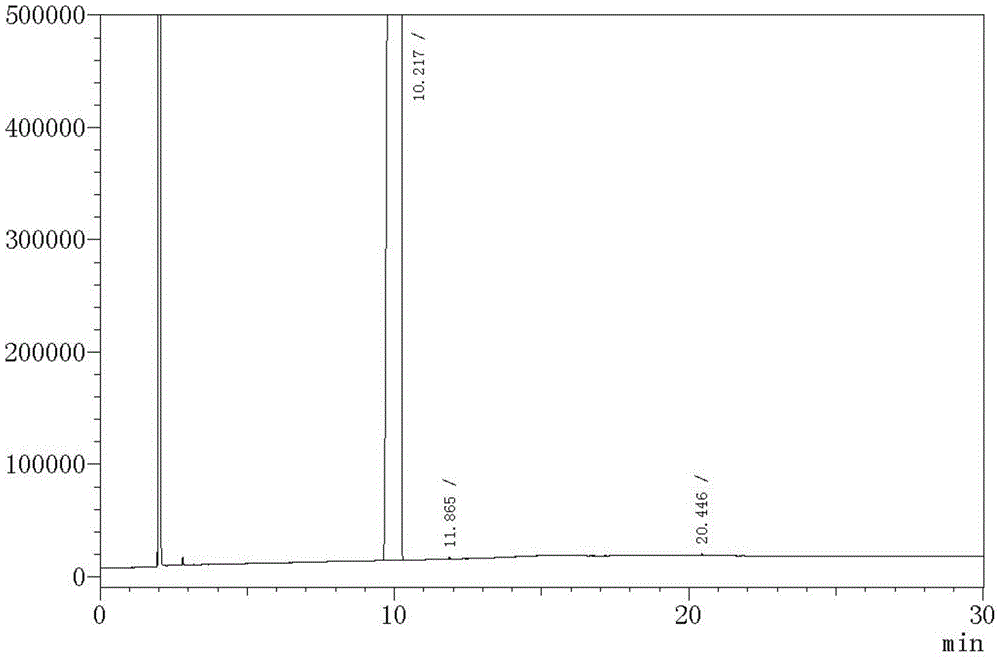

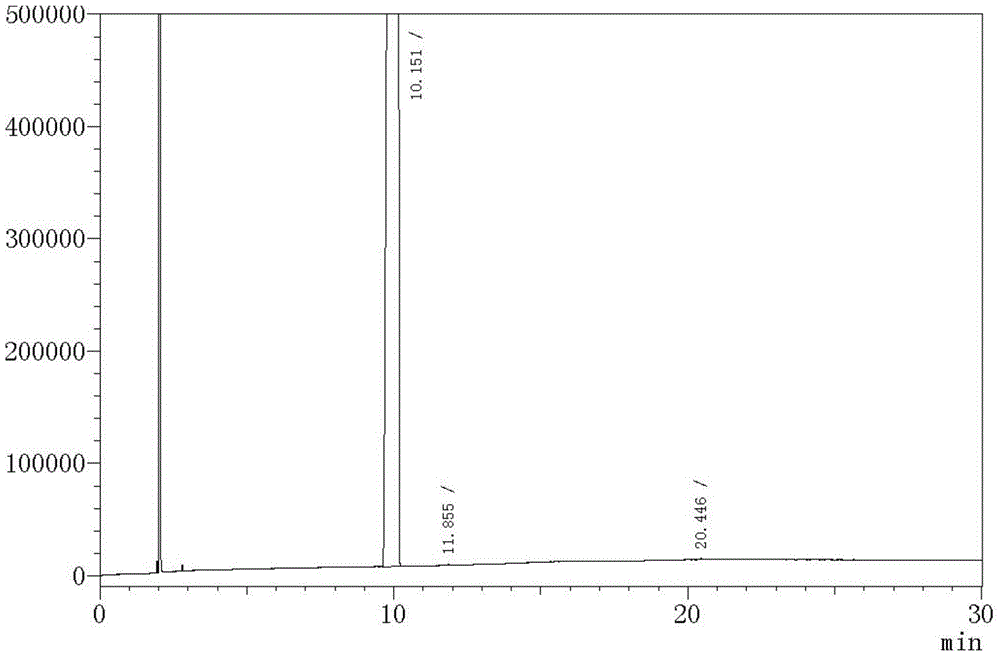

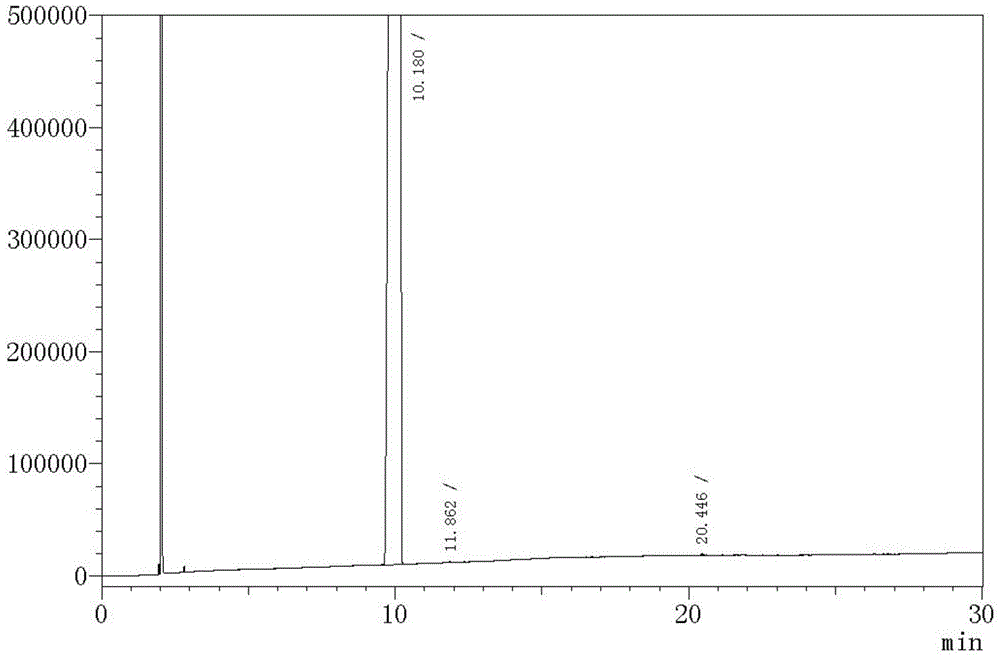

Embodiment 1

[0038] Gas chromatography analysis of industrially produced 4-ethoxy-2,3-difluorophenol: Take industrially produced 4-ethoxy-2,3-difluorophenol samples. Refer to the operating conditions to set the gas chromatographic conditions. The oven temperature rise program: keep at 80°C for 0 min, raise the temperature to 140°C for 0 min at a rate of 5°C / min, then raise the temperature to 280°C for 5 min at a rate of 20°C / min; Inlet temperature: 280°C; detector temperature: 300°C; column flow: 1.0ml / min; chromatographic gas flow setting: hydrogen: 40ml / min, air: 400ml / min; split ratio: 50 / 1; Set the conditions of the gas chromatography. After the baseline is stable, use a 10 μL micro-sampler to inject samples from the injection port. The injection volume is 1 μL. Function, using the area normalization method to calculate the purity of 4-ethoxy-2,3-difluorophenol; parallel measurement 4 times, the difference between any two parallel measurement results shall not be greater than 0.1%, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com