Light-duty full medium self-supporting type optical cable

A self-supporting optical cable, all-media technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of increasing the manufacturing cost of the optical cable and increasing the weight of the optical cable, and achieve the effect of easy laying, light weight and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

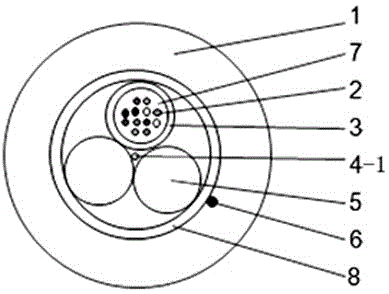

[0018] Such as figure 1 As shown, a light-weight all-dielectric self-supporting optical cable includes an outer sheath 1 and a cable core. An open cable 6 is set on the inner wall of the outer sheath, which can withstand a certain pulling force and higher temperature, and realize all-weather communication. It is napped and environmentally friendly. It can easily peel off the outer sheath of the optical cable, which is convenient for construction. The cable core is composed of an optical unit 3 and two non-metal strengthening units 5SZ twisted, which reduces the diameter of the optical cable, simplifies the structure of the optical cable, and is beneficial to the structure of the optical cable Due to the light weight, high tensile strength, and low elongation of the non-metal reinforced unit, the tensile strength of the optical cable is ensured, and it is easy to lay. The optical fiber 2 is arranged in the optical unit and filled in the entire optical unit and used for In order t...

Embodiment 2

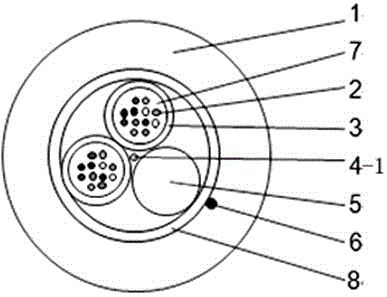

[0020] Such as figure 2 As shown, the structure is basically the same as that of Embodiment 1, the difference is that the cable core is formed by twisting two optical units 3 and a non-metallic strengthening unit 5SZ.

Embodiment 3

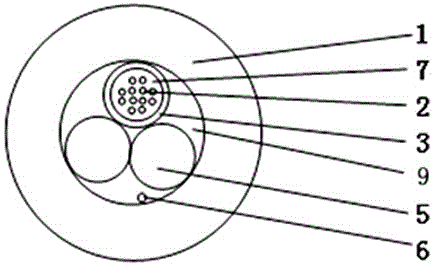

[0022] Such as image 3 As shown, a light-weight all-dielectric self-supporting optical cable includes an outer sheath 1 and a cable core. An open cable 6 is set on the inner wall of the outer sheath, which can withstand a certain pulling force and higher temperature, and realize all-weather communication. It is napped and environmentally friendly. It can easily peel off the outer sheath of the optical cable, which is convenient for construction. The cable core is composed of an optical unit 3 and two non-metal strengthening units 5SZ twisted, which reduces the diameter of the optical cable, simplifies the structure of the optical cable, and is beneficial to the structure of the optical cable Due to the light weight, high tensile strength, and low elongation of the non-metal reinforced unit, the tensile strength of the optical cable is ensured, and it is easy to lay. The optical fiber 2 is arranged in the optical unit and filled in the entire optical unit and used for In order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com