A light energy total reflection concentrator

A technology of total reflection and concentrator, which is applied in the field of solar energy and optical concentrator, can solve the problem of not being able to completely get rid of reflection attenuation, etc., and achieve the effect of simple structure and high energy transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

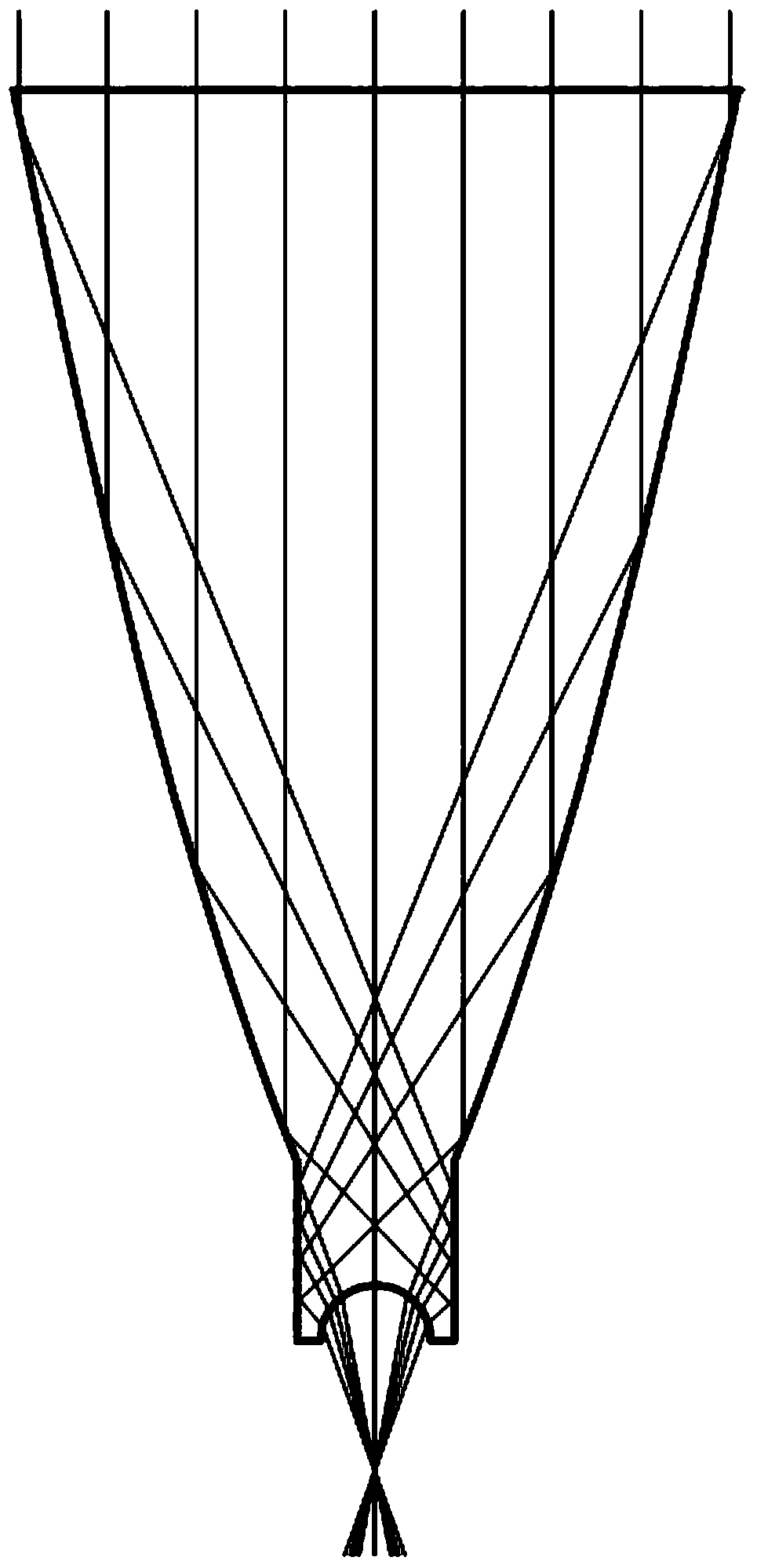

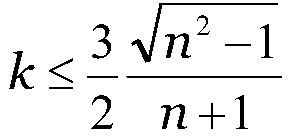

[0055] Such as figure 1 and figure 2 As shown, a light energy total reflection concentrator performs light concentrating and light transmission according to the principle of total reflection. The light energy total reflection concentrator is made of a whole piece of light-transmitting material, including parabolic concentrator 1, Cylindrical reflector 2 and circular arc refraction surface 3, the three are arranged sequentially along the same axis of symmetry; the parabolic concentrator 1 is connected end to end with the cylindrical reflector 2, and the circular arc refraction surface 3 is formed by the bottom of the cylindrical reflector 2 A hemispherical body is dug out from the inner side; the parallel light beam parallel to the axis of symmetry is incident from the top of the parabolic concentrator 1;

[0056] The light energy total reflection concentrator is made of a whole piece of light-transmitting material. The light energy total reflection light concentrator is a w...

Embodiment 2

[0080] Such as Figure 8 As shown, a plurality of light energy total reflection concentrators described in Embodiment 1 are combined in parallel to form a unidirectional large-section concentrator system. The large-section concentrating system increases the receiving surface of the parallel incident light beam on the plane by arranging a plurality of light energy total reflection concentrators of the present invention in the same plane structure, and obtains higher density energy flow light energy .

Embodiment 3

[0082] Such as Figure 9 As shown, a plurality of light energy total reflection concentrators described in Embodiment 1 are combined in parallel to form a multi-directional section light concentrating system. The multi-section concentrating system sets a kind of light energy total reflection concentrator connected in parallel at multiple angles, collects sunlight as parallel incident beams at each time period as much as possible, prolongs the best lighting time period, and ensures that each time period The best light source can be collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com