Method and system for manufacturing an alignment film

A production method and alignment film technology, which are applied in the field of alignment film production methods and systems, can solve problems such as uneven alignment ability, and achieve the effects of reducing the difference in alignment ability, reducing uneven alignment ability, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

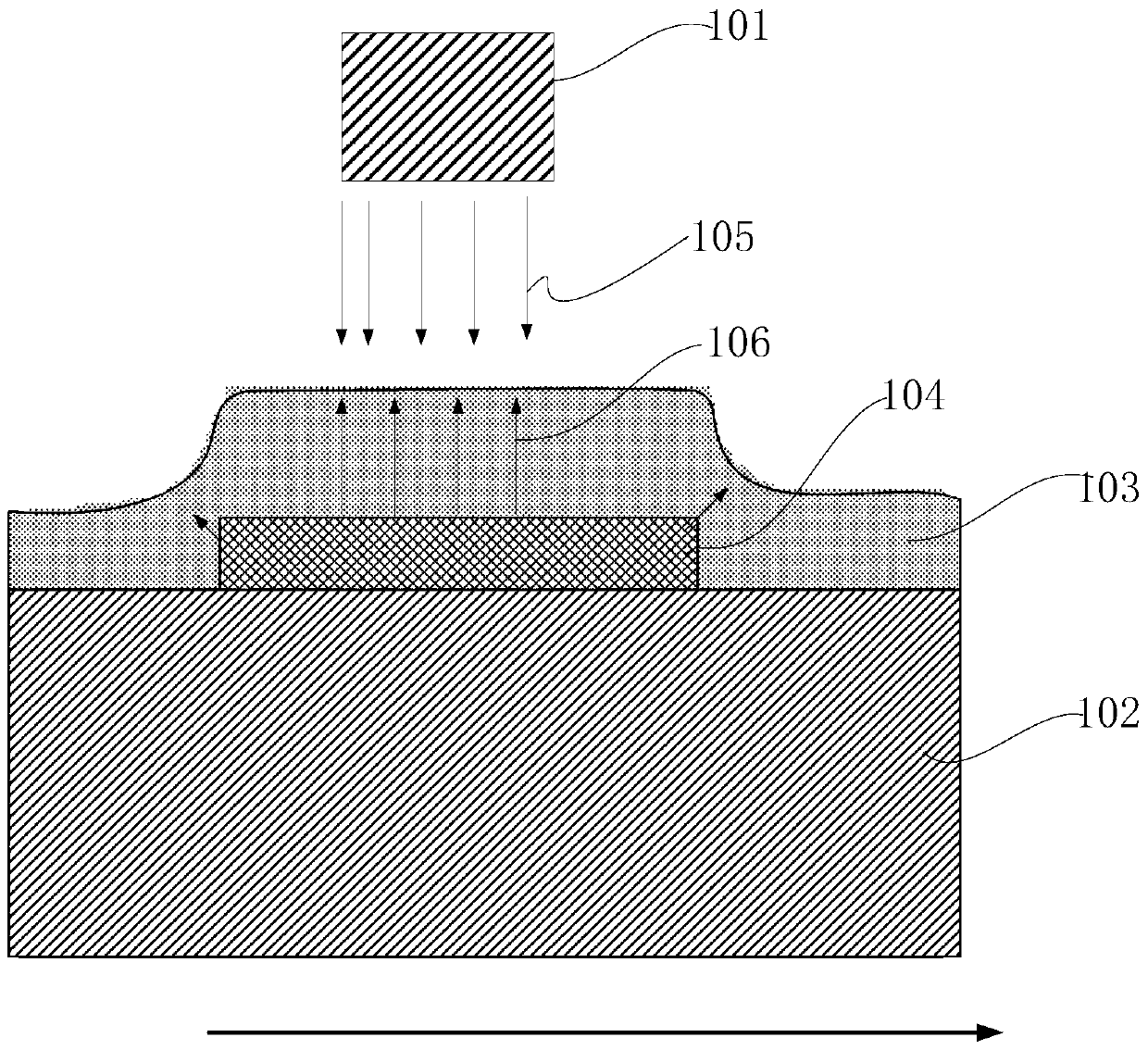

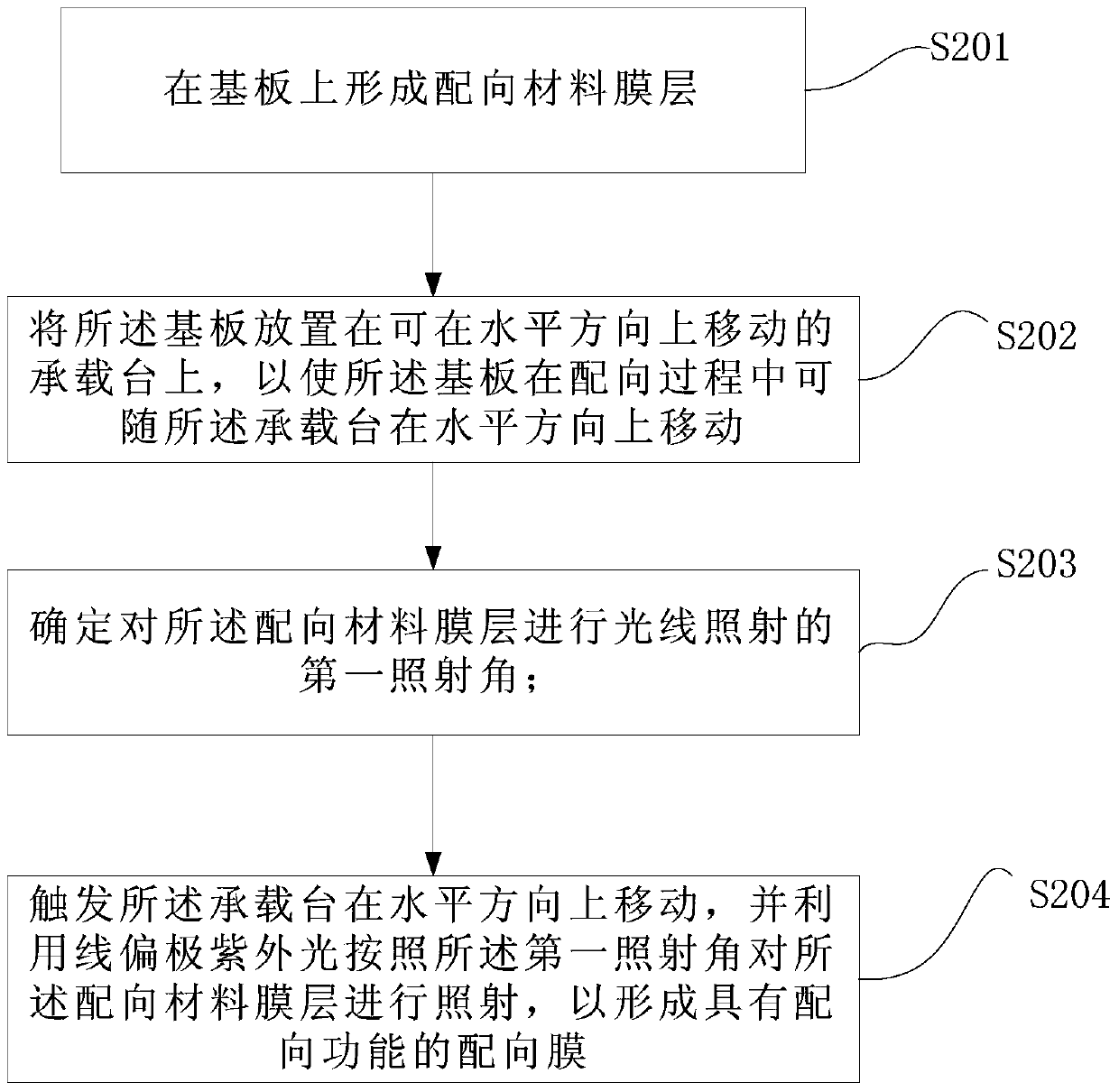

[0049] Such as figure 2 As shown, this embodiment provides a method for fabricating an alignment film, which is used to fabricate an alignment film on a substrate, including the following steps:

[0050] S201, forming an alignment material film layer on the substrate;

[0051] In this step, a film layer of an alignment material can be coated on the substrate to prepare for the preparation of an alignment film with alignment capability; in this embodiment, the alignment material can be a high molecular polymer;

[0052] Preferably, the substrate in this embodiment may be an array substrate, or may also be a color filter substrate; when an alignment film is formed on the array substrate, since the array substrate includes: a pixel electrode layer, which is used to form a plurality of comb-shaped structures Pixel electrode (ITO Slit), so S201 can specifically include:

[0053] An alignment material film layer is formed on the pixel electrode layer.

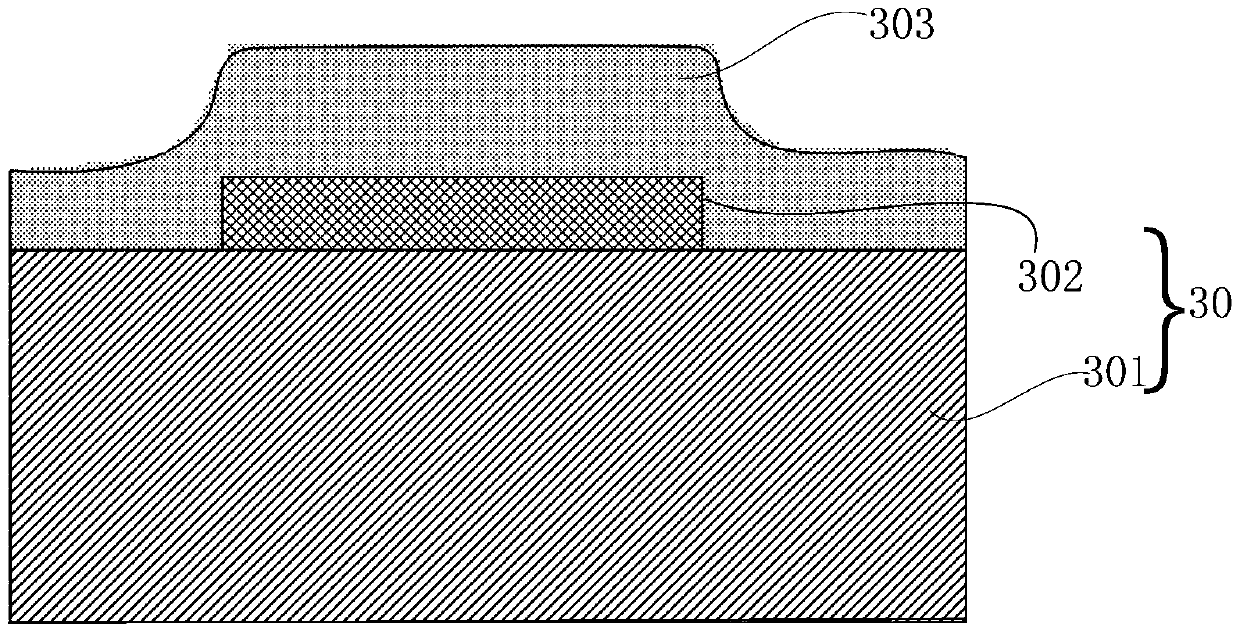

[0054] Such as image 3 As...

Embodiment 2

[0081] This embodiment provides a manufacturing system for an alignment film, which is used to form an alignment film on a substrate, such as Image 6 shown, including:

[0082] The carrying platform 601 movable in the horizontal direction is used to carry the substrate 602 formed with the alignment material film layer 603, and drives the substrate 602 to move in the horizontal direction;

[0083] In this embodiment, the substrate 602 may be an array substrate or a color filter substrate, taking the array substrate as an example, Image 6 The middle array substrate 602 includes: a pixel electrode 602b and a substrate film layer 602a; wherein the substrate film layer is composed of a substrate substrate, a metal layer and a film layer;

[0084] A light irradiator 604, located above the carrying platform 601, is used to emit line polarized ultraviolet light to irradiate the alignment material film layer 603 moving in the horizontal direction, so as to form an alignment film wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com