Handheld two-component sealant injector

A two-component, glue injector technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems such as being unsuitable for large-scale automated production, large occupied area of site appliances, and large operating space limitations, etc. Achieve the effect of excellent operation direction and applicability, reduction of production area, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

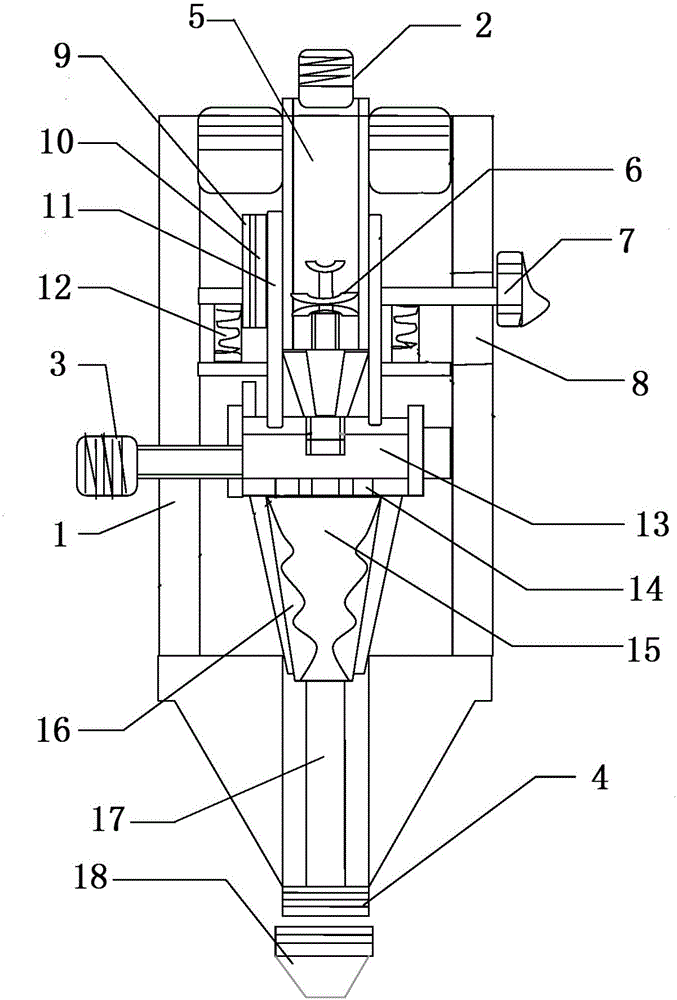

[0011] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0012] Such as figure 1 As shown, a hand-held two-component glue injector mainly includes a shell 1, a liquid inlet 2 set on the top of the shell 1, a glue inlet 3 set in the middle of the shell 1, and a bottom of the shell 1 The glue outlet 4, the liquid inlet 1 is provided with a liquid inlet chamber 5, the liquid inlet chamber 5 is provided with a spherical liquid inlet valve 6, and the spherical liquid inlet valve 6 is connected with the handle 7, the The handle 7 is connected with the stroke controller 8, and the handle 7 is respectively connected with the slide rail 9, the slide bar 10, and the sliding sleeve 11 provided with the lower pressing plate. A glue injection chamber 13 is arranged below the liquid chamber 5, and the glue injection chamber 13 is connected with the glue inlet 3. A dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com