Indirect Thermal Desorption Unit

A thermal desorption, indirect technology, applied in the restoration of contaminated soil, etc., can solve the problems of high disposal cost, complicated equipment, and difficult sealing of the drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

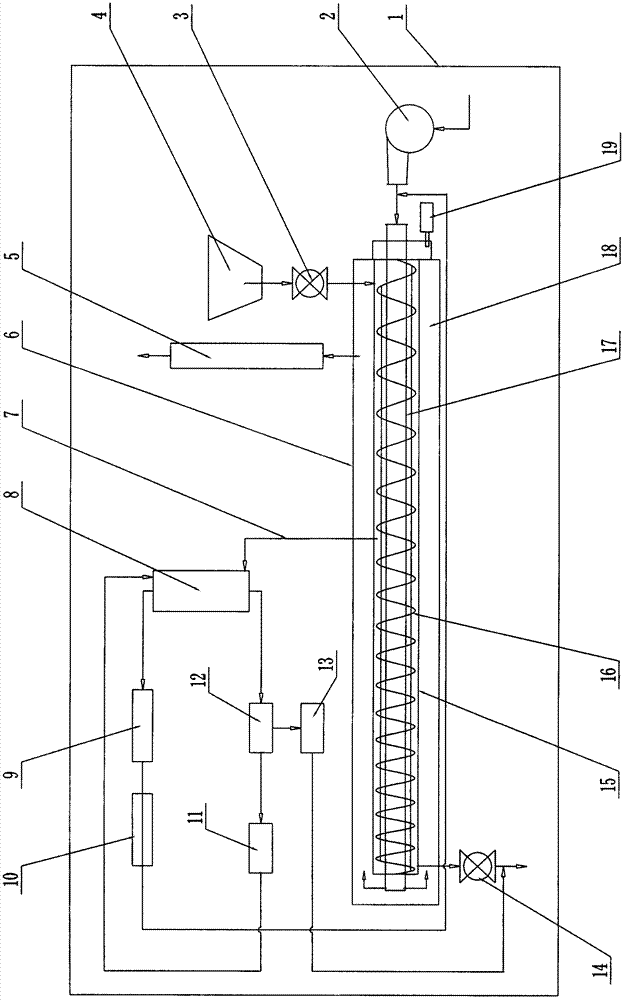

[0020] The indirect thermal desorption device of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0021] Such as figure 1As shown, the indirect thermal desorption device of the present invention includes a skid body 1, and the skid body 1 is provided with a feed hopper 4, a feed air locker 3, an outer cylinder 15, a discharge air locker 14, a motor 19, and a burner 2 , chimney 5, spray tower 8, activated carbon adsorption tank 9, induced draft fan 10, oil-water separator 12, air cooler 11 and water treatment 13, the outside of outer cylinder 15 is covered with insulation shell 6, and outer cylinder 15 is provided with shaftless Auger 16, shaftless auger 16 is inserted with combustion tube 17, the motor shaft of motor 19 is connected with shaftless auger 16 by drive system, burner 2 is connected with the right end of combustion tube 17, and the left end of combustion tube 17 is connected with The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com