Overhead high-voltage power transmission line strain clamp drainage plate bolt tightening robot

A technology of high-voltage transmission lines and strain-resistant clamps, which is applied in the direction of overhead lines/cable equipment, metal processing, metal processing equipment, etc., and can solve the problems of poor self-adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

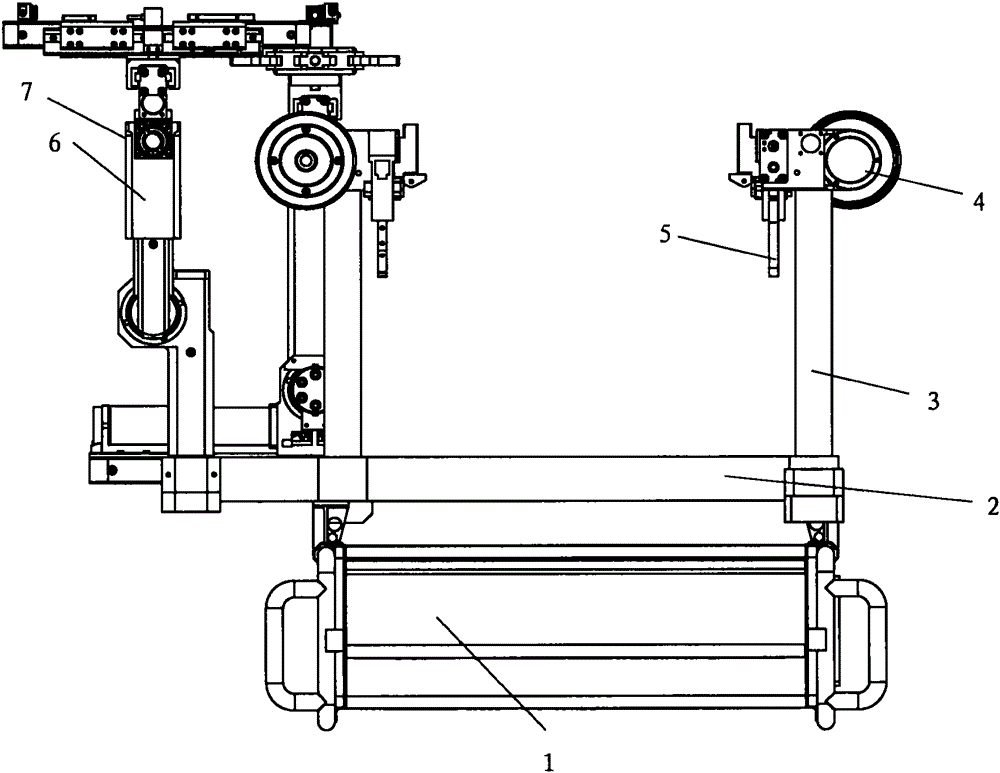

[0021] see figure 1 . The body 1 of the overhead high-voltage transmission line tension clamp drainage plate bolt fastening robot of the present invention includes a non-obstacle-crossing inspection robot platform 2 and at least three degrees of freedom (that is, rotational motion, longitudinal reciprocating motion and lateral reciprocating motion) ) of the operating robot arm. The non-obstacle-crossing inspection robot platform 2 includes two fixed arms 3 arranged anti-symmetrically on the body, the walking wheels 4 and the line clamping claws 5 coupled to the fixed arms 3, and the Equipotential parts. The first working arm 6 and the second working arm 7 are respectively arranged on the left and right sides of the machine body 1 . When the robot needs to perform live work, the non-obstacle-crossin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com