Precision outward staying type intelligent industrial robot actuator

An industrial robot and intelligent technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of not allowed to touch, general-purpose actuators cannot complete the work, etc., to achieve convenient adjustment, fewer actuator components, and ensure safe production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

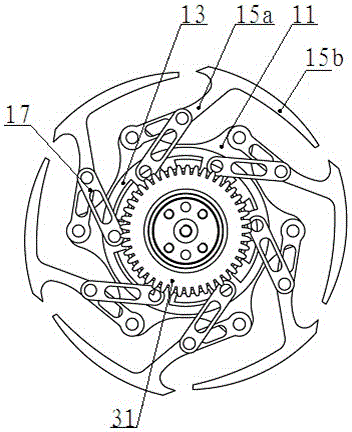

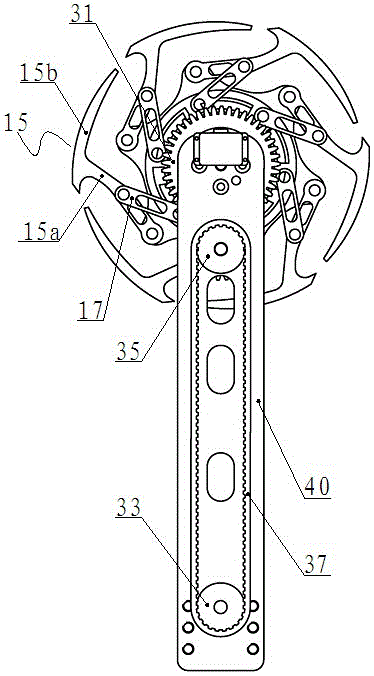

[0019] like figure 1 and figure 2 As shown, a precision external support type intelligent industrial robot actuator includes a drive mechanism, a transmission mechanism and an actuator.

[0020] The actuator includes a chassis 11, a turntable 13, a plurality of external support grippers 15, and a plurality of connecting rods 17 corresponding to the external support grippers 15 one-to-one;

[0021] One end of the outer support gripper 15 is fixed on the chassis 11, and a plurality of outer support grippers 15 are evenly distributed on the circumferential edge of the chassis 11, and an even number of outer support grippers are preferentially selected, and the outer support gripper 15 is opened to form a round face.

[0022] During specific implementation, the outer support gripper may preferably adopt the following structure: the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com