Large fold-to-span ratio solar wing

A solar wing and folding aspect ratio technology, which is applied in the field of large folding aspect ratio solar wings, can solve the problems that it is difficult to meet the special application requirements of light and small satellite platforms, the solar wing deployment mechanism is complex, and the mass is heavy, and the product is light in weight and structure. Simple and highly reliable mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

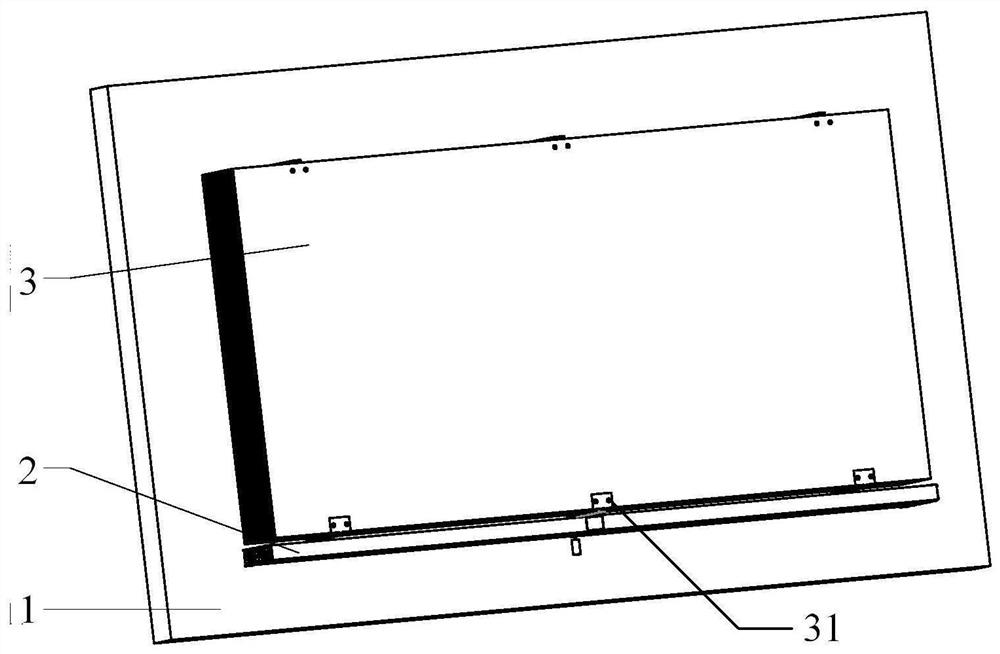

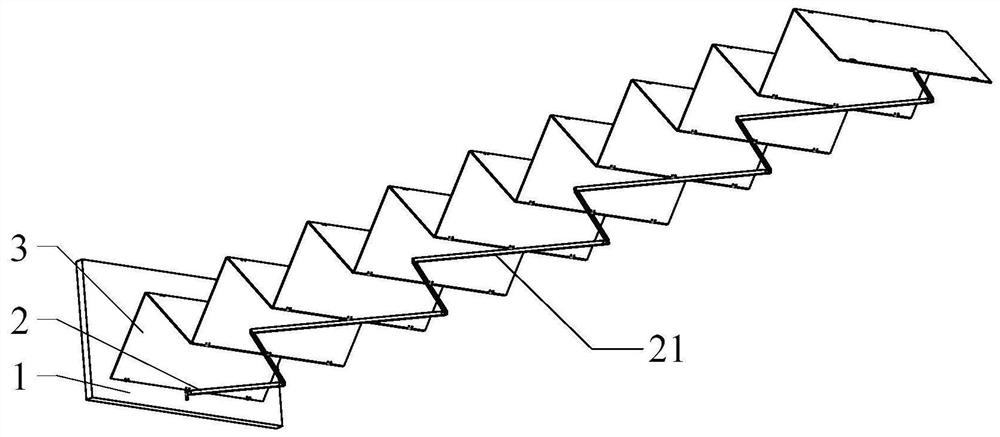

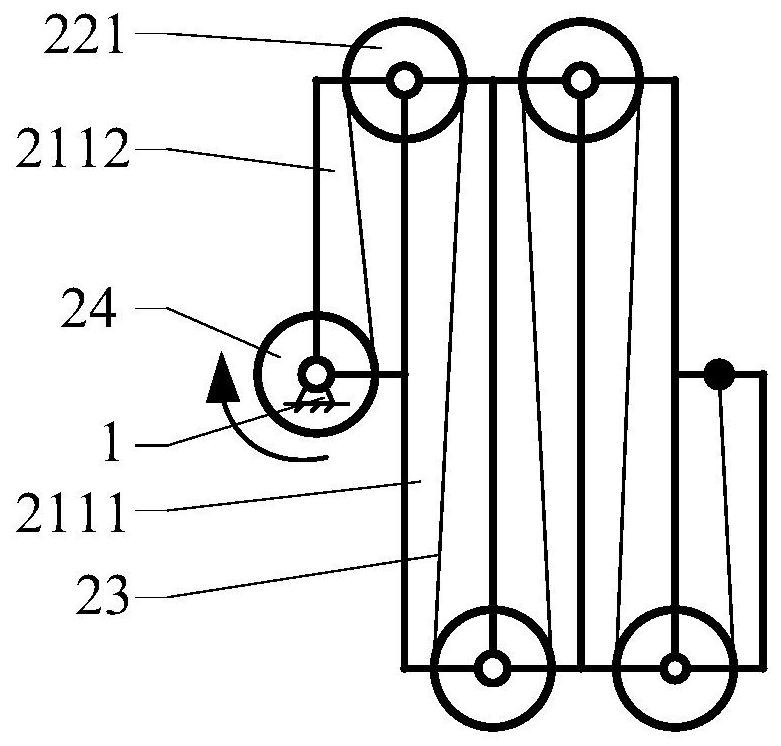

[0039]The large folding-to-span ratio solar wing provided by the present invention includes a deployment mechanism 2 and a solar cell substrate assembly 3 arranged on a satellite body 1; the deployment mechanism 2 includes a deployment rod assembly 21, a guide roller assembly 22 and a driving rope 23; The deployment rod assembly 21 includes a plurality of deployment rods 211 and a first hinge 212 connecting the deployment rods 211 to form an open-loop chain structure. The deployment rod assembly 21 can be folded and unfolded. The sides of the adjacent deployment rods 211 abut against each other, and in the unfolded state, the ends of the adjacent deployment rods 211 abut against each other; the guide roller assembly 22 includes a guide roller 221 located at the joint of the deployment rod 211 and coaxial with the hinge; One end of the rod assembly 21 is hinged to the satellite body 1 through a second hinge 213, and a reel 24 coaxial with the second hinge 213 is provided at the ...

Embodiment 2

[0047] The difference from Embodiment 1 is that the solar cell substrate assembly 3 is composed of a plurality of rigid substrates, and the rigid substrates are hinged by at least one third hinge 31, and the two ends of the solar cell substrate assembly 3 are connected to the unfolded Both ends of the rod assembly 21 are hinged, and the middle parts of the even-numbered seams of all rigid substrates are hinged with the middle parts of the expansion rod 211 .

[0048] The length of the rigid base is half the length of the long deployment rod 2111.

[0049] The advantage of this embodiment is that the shape of the rigid substrate is determined when it is folded and unfolded. Compared with the flexible substrate, space needs to be reserved to prevent rigid bending, and the folded state of the rigid substrate takes up less space. When the length of the rigid substrate is half of the length of the long deployment rod 2111, the backlight surface of the solar cell substrate assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com