Belt-type fermented material sheeter

A technology for fermented materials and tablet presses, applied to presses, manufacturing tools, etc., can solve problems such as production failure, difficulty in feeding materials, and material slippage, and achieve the effects of simple and practical structure, easy maintenance, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

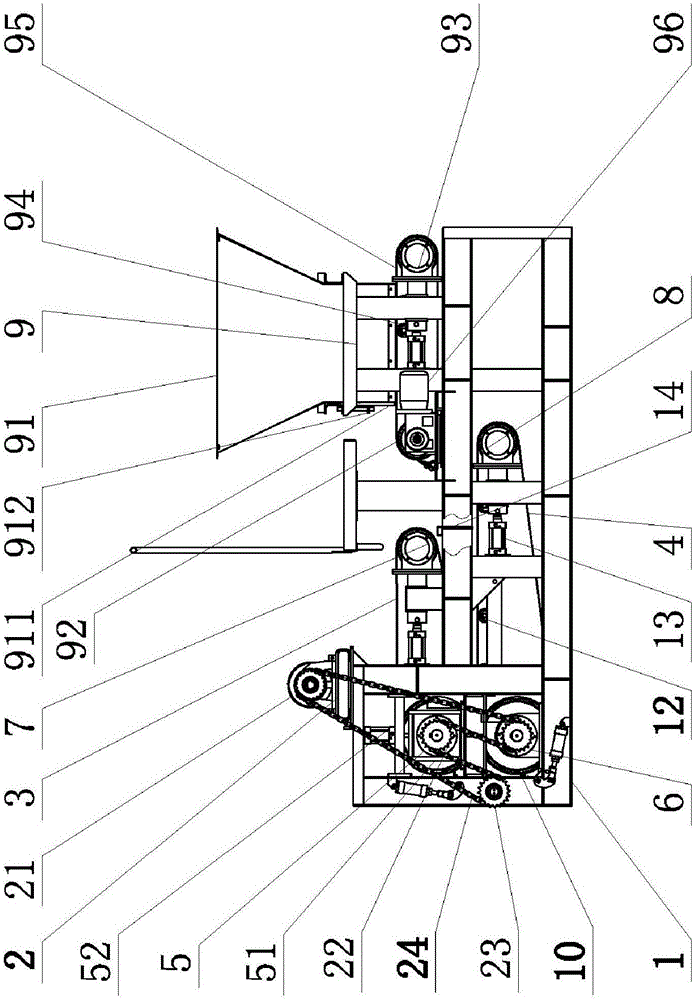

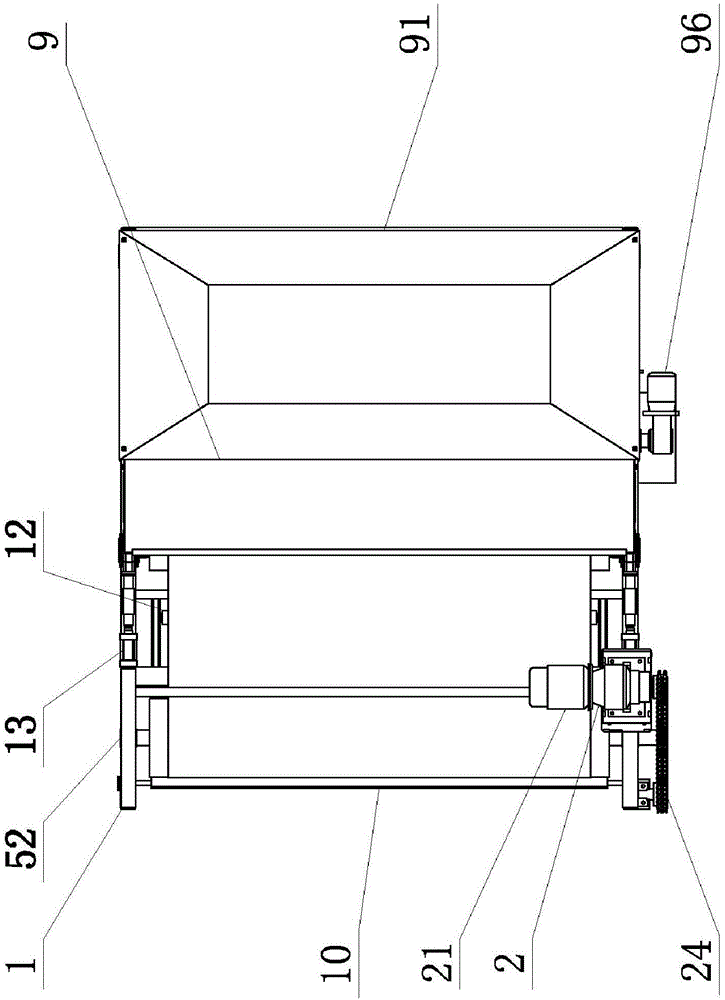

[0050] see Figure 1 to Figure 4 As shown, the belt-type fermentation material tablet press of the present invention is mainly composed of a frame 1, a driving device 2, an upper pressing belt 3, a lower pressing belt 4, an upper pressing belt driving roller 5, and a lower pressing belt driving roller 6 , The upper pressing belt redirecting roller 7, the lower pressing belt redirecting roller 8, the material distribution device 9 and the discharge scraper 10 are composed. The driving device 2, the upper pressing belt driving roller 5, the lower pressing belt driving roller 6, the upper pressing belt redirecting roller 7, the lower pressing belt redirecting roller 8, the distributing device 9 and the discharge scraper 10 are installed on the machine Rack 1. The driving device 2 is in transmission connection with the upper pressing belt driving roller 5 and the lower pressing belt driving roller 6 . The upper pressing belt 3 is wound between the upper pressing belt driving rol...

Embodiment 2

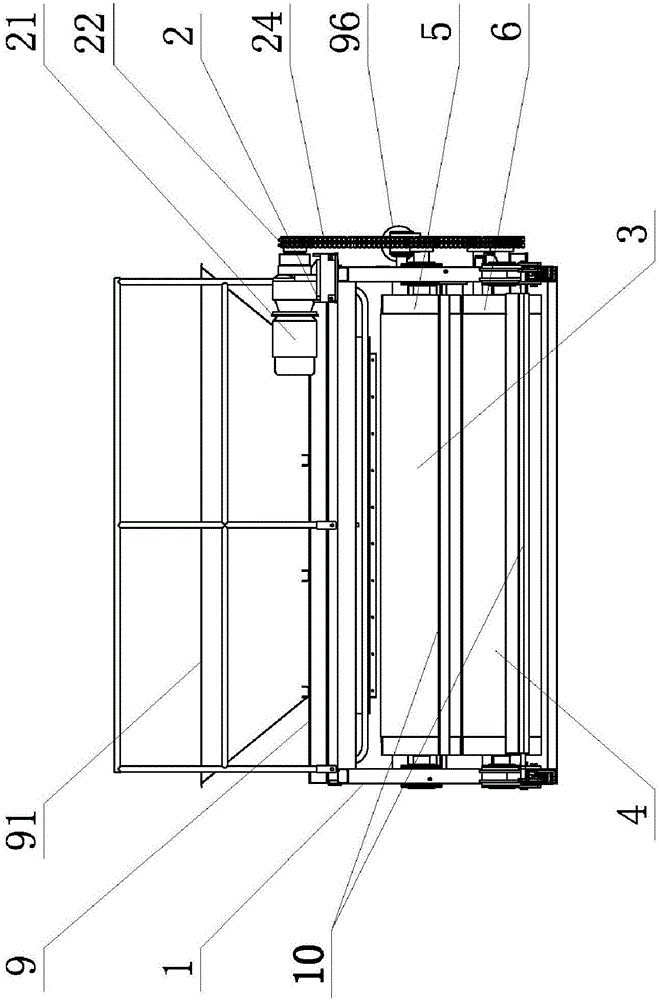

[0066] see Figure 5 to Figure 8 As shown, the second embodiment of the present invention is similar to the first embodiment, the only difference is that on the basis of the first embodiment, the lower pressing belt driving roller 6 is originally on a vertical line with the upper pressing belt driving roller 5 , move a certain distance to the outside, the positions of other rollers remain unchanged, lengthen the length of the lower pressing belt 4, and install a lower pressing belt driving roller 6 with the same diameter as the pressing belt driving roller 6 at the original position of the lower pressing belt driving roller 6. Binder belt power idler 15. A transmission sprocket 22 is installed on the mandrel of the lower pressing belt power idler 15. This transmission sprocket 22 is a double-row sprocket, which is engaged with the transmission sprocket 22 on the drive motor 21 through a transmission chain 24. Simultaneously carry out engagement transmission with the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com