Cross printing method for CIJ ink-jet printer

A inkjet printer and inkjet printing technology, which is applied in printing and other directions, can solve the problems of low printing accuracy, printing height change, and poor printing quality, and achieve the effect of improving deflection accuracy, achieving printing accuracy and quality, and avoiding character confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

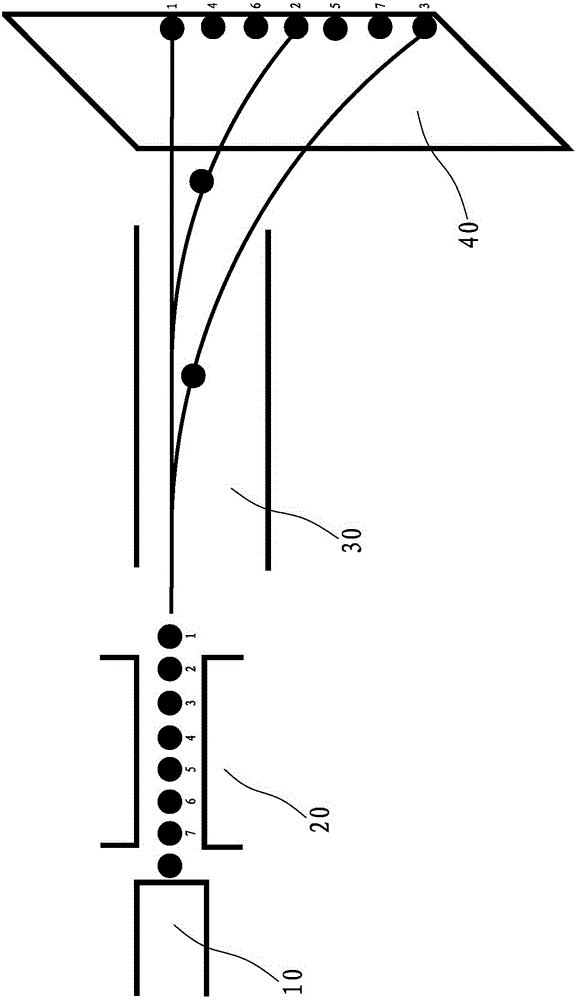

[0019] The CIJ inkjet printer cross-printing method disclosed by the present invention comprises the following steps:

[0020] S1: Generate control data according to the graphic data to be printed, and send the control data to the print head. The control data includes the number of charged ink drops and the charging amount of each ink drop;

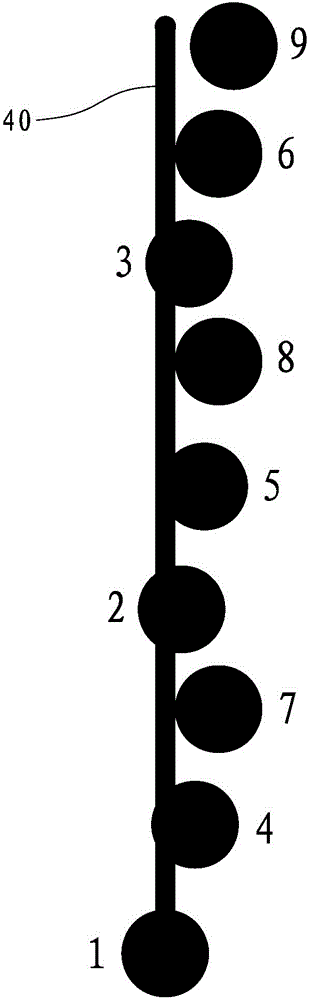

[0021] S2: The nozzles of the print head eject ink droplets at high speed, and the charging electrode selects ink droplets for charging. Each character matrix is composed of several columns of ink droplets. There are n Δq differences in electricity, n≥2, where one Δq is the electricity difference between the two closest ink dots on the printed matter;

[0022] S3: Since the electric charge carried by the two ink droplets passing successively in the deflection electric field differs by n (n≥2) Δq, there is at least one ink dot between the ink dots successively printed on the printed matter in a row of ink droplets, Finally, each column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com