Warehousing system and control method thereof

A warehousing system and warehousing technology, which is applied in the field of automated warehousing systems and controls, can solve problems such as low work efficiency and low space utilization, and achieve the effects of increasing storage density, improving storage space utilization, and improving handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

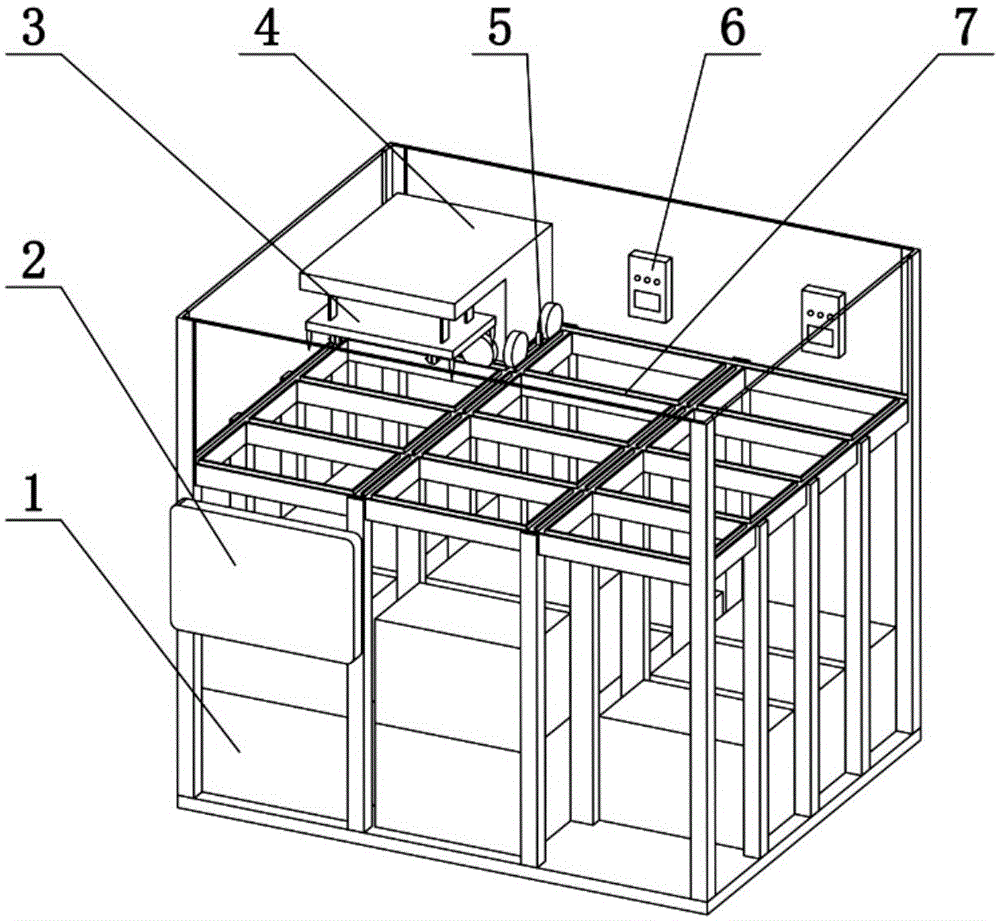

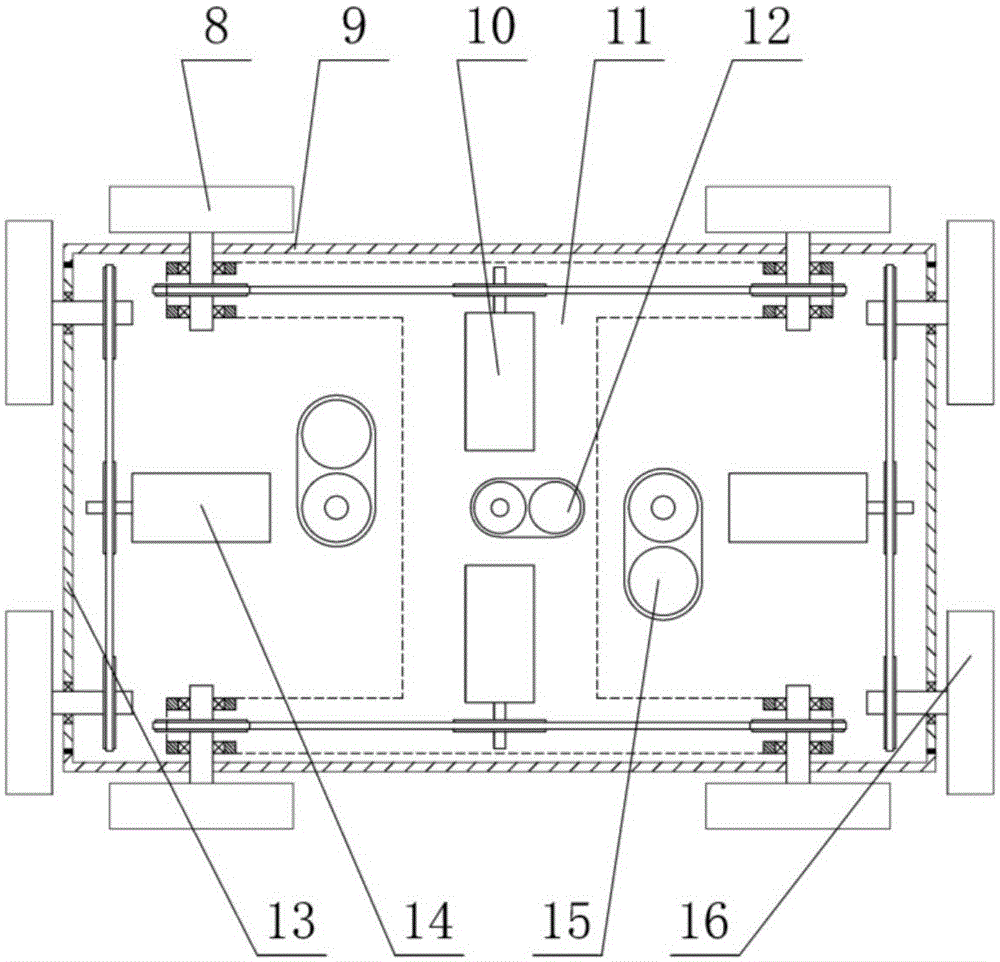

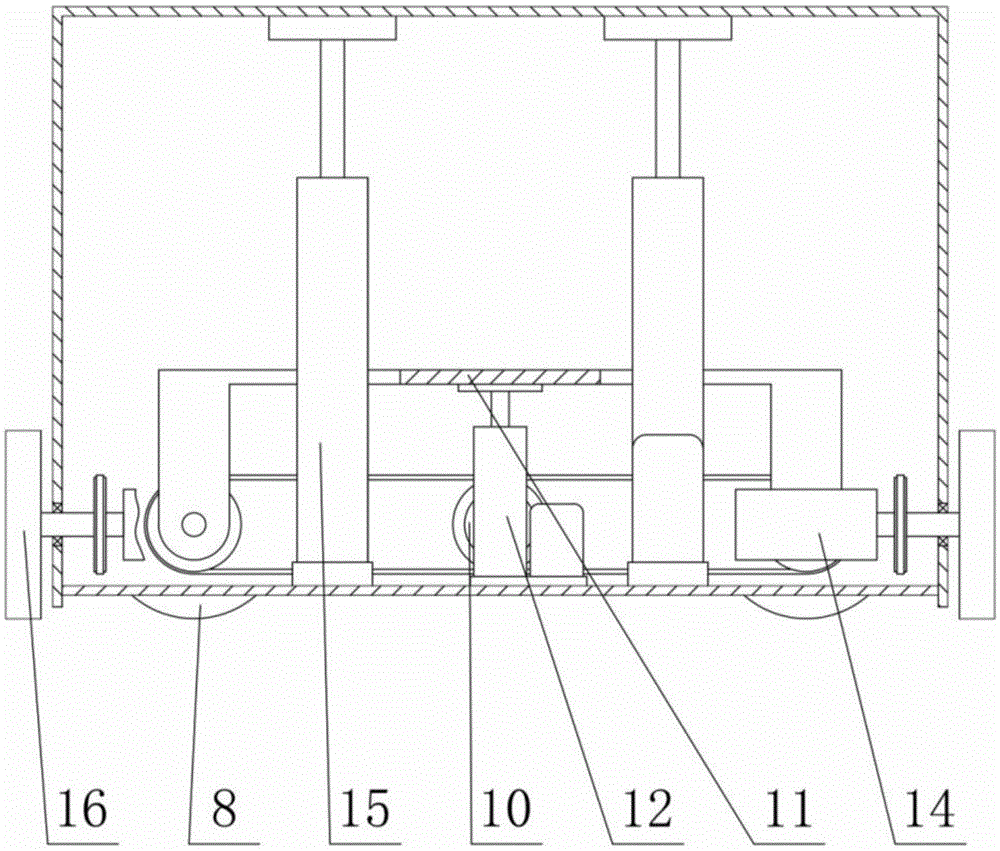

[0030] see figure 1, which is a schematic structural diagram of the high-density storage system of the present invention. As shown in the figure, the high-density storage system includes: three-dimensional storage shelves, the three-dimensional storage shelves are modularized from a plurality of storage compartments, each storage compartment can place a storage box 1, according to The required floor area and height are built, and the frame of the storage compartment is set as a movable type, which can be adjusted as a whole according to the needs at any time; a storage compartment is set at the bottom of the three-dimensional storage shelf as the entrance of the storage box, and the storage compartment to be stored The storage box is transported to the entrance of the storage box, and then transported by the transport robot 4 to the pre-designated position; the top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com