Feeding device

A technology of feeding device and transmission frame, which is applied in the field of mechanical equipment, can solve the problems of inapplicability, and achieve the effects of saving space, easy disassembly and assembly, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

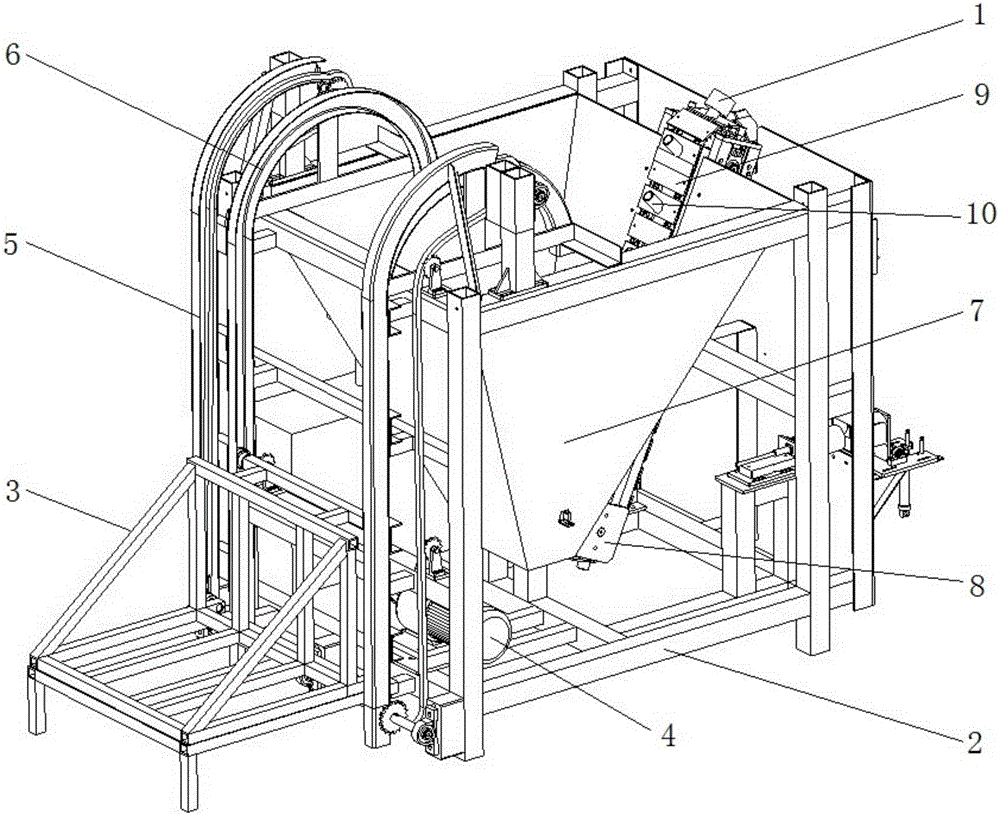

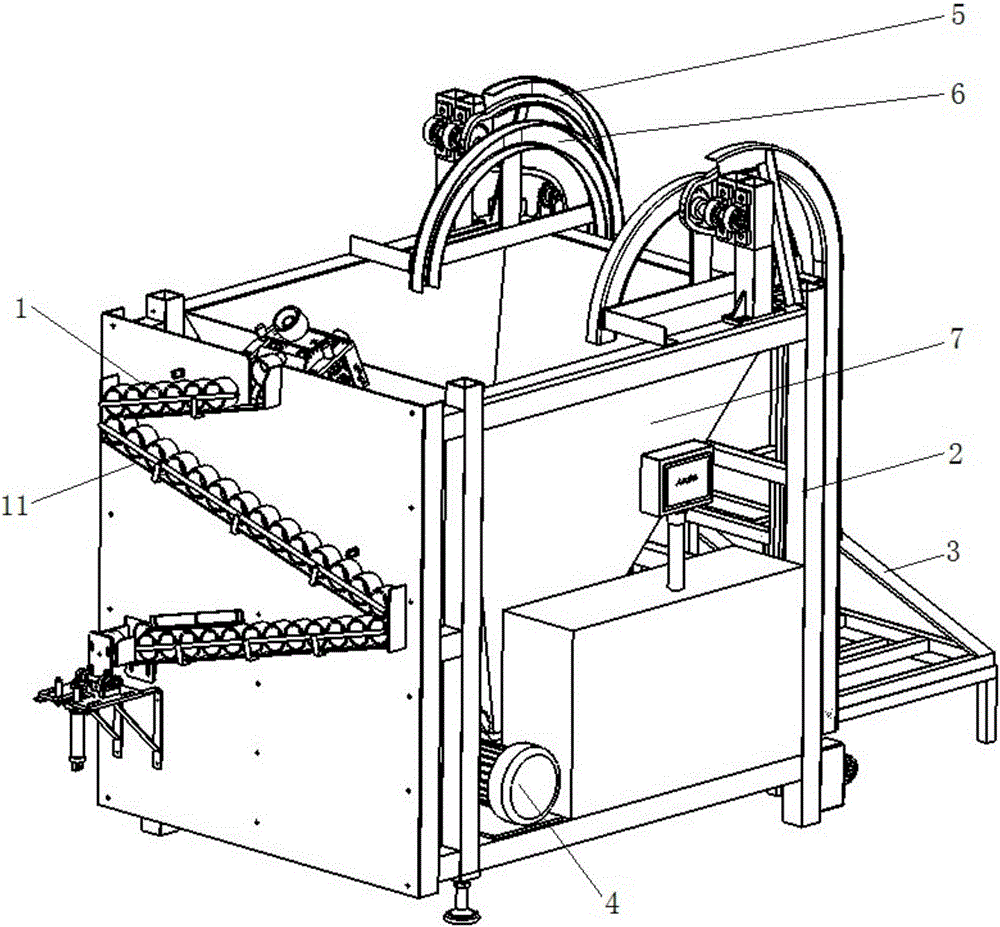

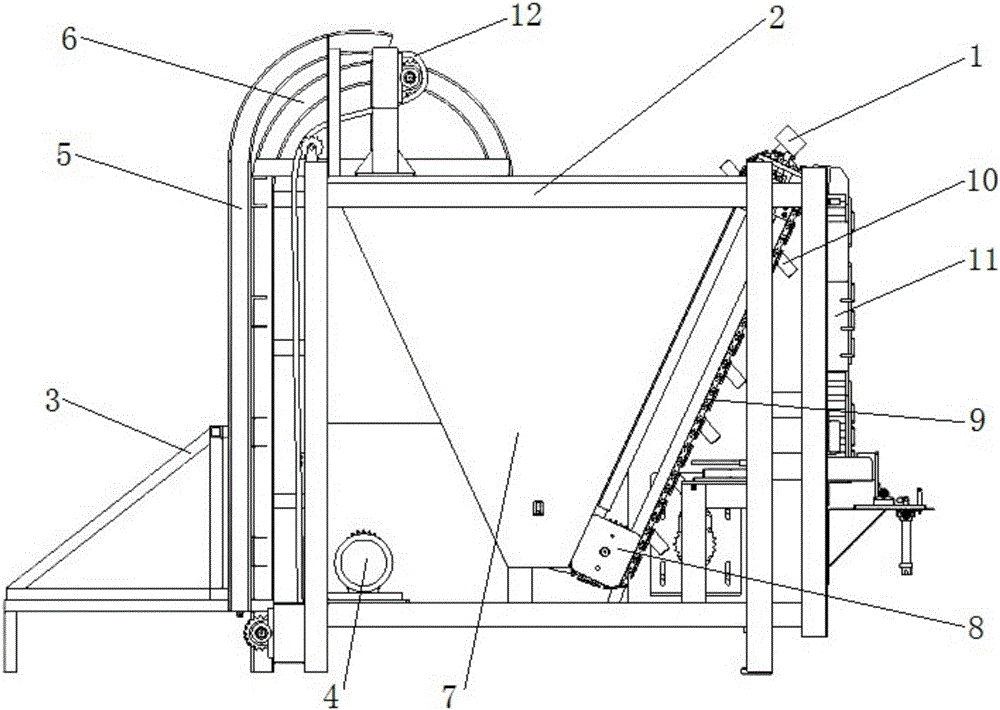

[0028] Such as Figure 1 ~ Figure 4 As shown, a feeding device is used to transport a cylindrical workpiece 1, including a bracket 2, and a tipping bucket type feeding mechanism, a hopper mechanism, a waterwheel mechanism and a clip-type slide mechanism arranged on the bracket 2 and connected in sequence , the tipping bucket feeding mechanism tilts the material box containing the workpiece 1, and pours multiple workpieces 1 into the hopper mechanism. After passing through the hopper mechanism, the workpieces 1 fall into the waterwheel mechanism one by one, and the waterwheel mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com