Color steel plate automatic stacker

An automatic stacking, color steel plate technology, applied in the directions of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of undiscovered patent publications, corporate losses and inconvenience, and easily damaged color steel plates, saving manpower and Material resources, convenient movement, and the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0037] The structures, connections and methods not described in detail in this patent application can be understood as common knowledge in this field.

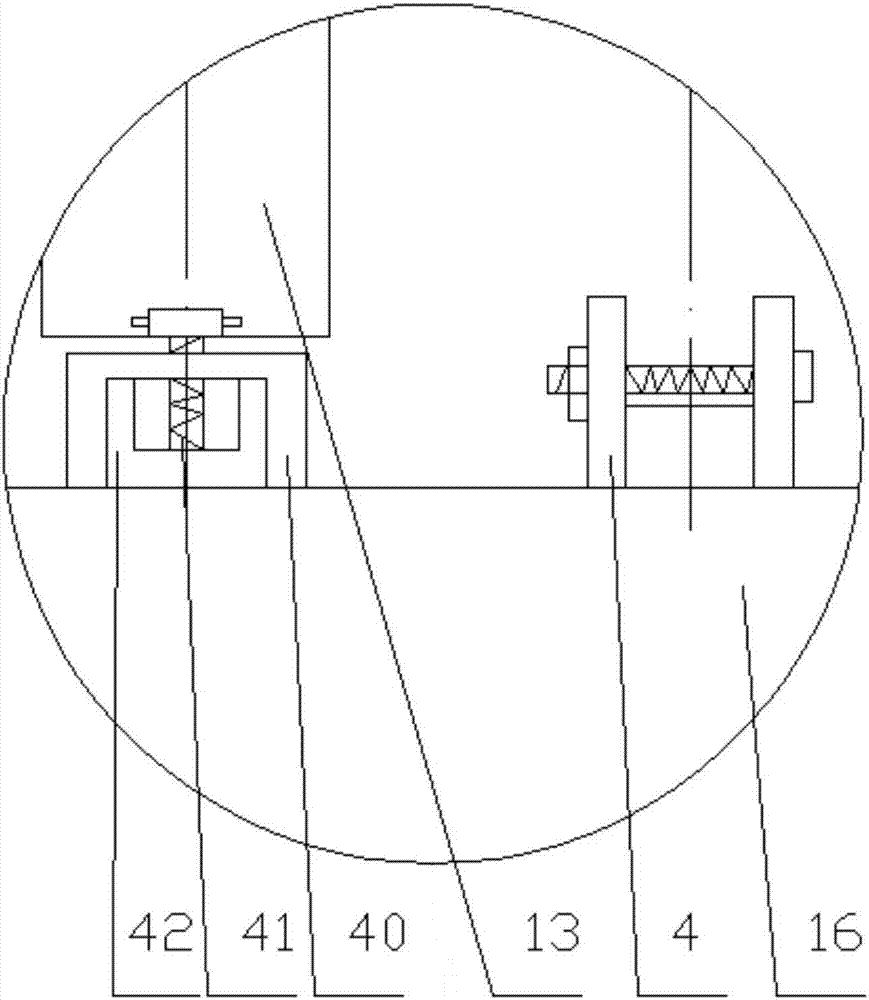

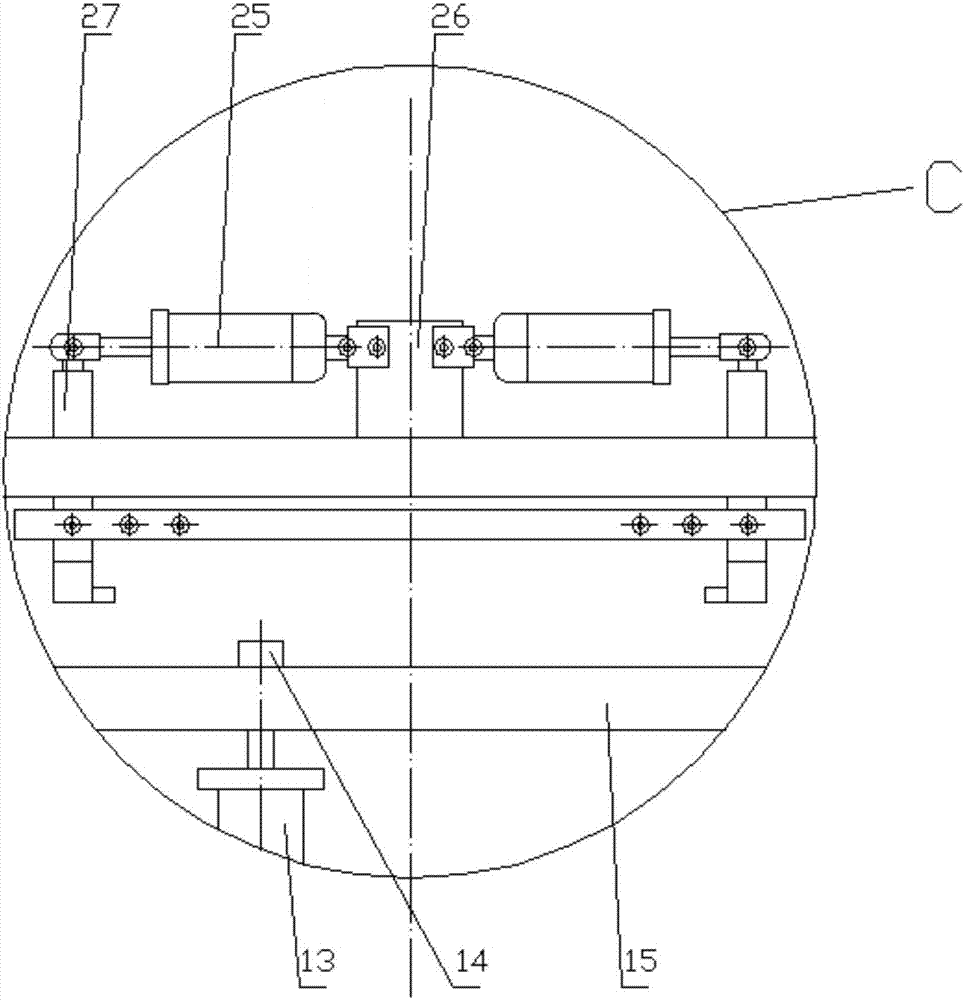

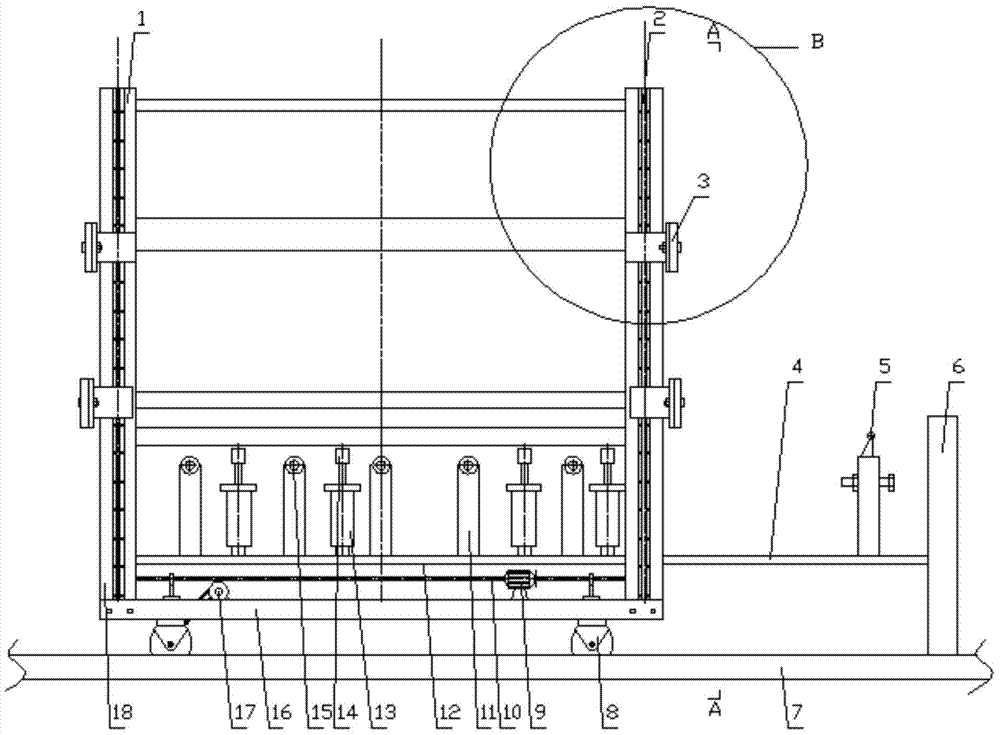

[0038] A color steel plate automatic stacker, such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the stacker includes a square frame 16, a lifting device 1, a transmission device 12, a clamping translation device 24 and a swing device 30, and the lifting device is arranged on one side of the square frame, and the transmission The device is installed at the bottom of the square frame, and a clamping translation device is installed on the lifting device above the transmission device. A swing device is arranged outside the clamping translation device, and the lifting device can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com