Self-thermal insulation concrete block

A technology for self-insulating blocks and hollow bricks, applied in the field of materials, can solve the problems of low fire resistance, labor and materials, short service life, etc., and achieve the effects of good fire resistance, good thermal insulation effect and obvious land saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing self-insulating blocks, comprising the following steps:

[0037] Step 1. After the Yellow River silt is stacked and settled for 6 months, transport it to the mud storage and mix it with the Yellow River cement and fly ash according to the ratio of parts by weight, remove weeds, grass roots and other sundries, and pre-homogenize to obtain the mixture 1;

[0038] Step 2: Take coal gangue according to the ratio of parts by weight and pulverize it with a hammer mill to a particle size of ≤2.5mm, send it to a box feeder with a forklift, and then transport it to a strong mixer with a belt conveyor for mixing with the mixture 1 for 8- 10 minutes, add 5-10 parts of water during stirring;

[0039] Step 3. The stirred mixture enters the QTY-15 vibration block forming machine through the belt conveyor, and is formed by cloth, vibration, and pressing at room temperature; the block forming time is 30-60 seconds per board, an...

Embodiment 1

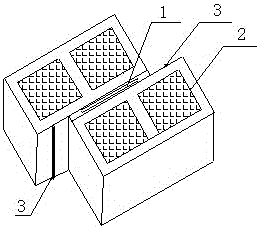

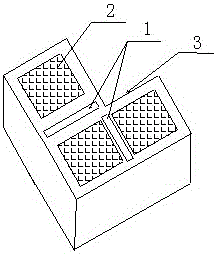

[0052] Embodiment 1 Z-shaped self-insulation block of the present invention

[0053] see figure 1

[0054] Step 1: Take 30 parts of the Yellow River silt and stack it for 6 months, transport it to the mud storage, mix it with 25 parts of the Yellow River cement, and 15 parts of fly ash according to the ratio of parts by weight, then remove weeds, grass roots and other sundries. Homogenize to obtain mixture 1;

[0055] Step 2: Take coal gangue according to the ratio of parts by weight and pulverize it with a hammer mill until the particle size is ≤2.5mm, send it into the box feeder with a forklift, measure it, and transport it together with the mixture 1 to a strong mixer for 10 minutes by a belt conveyor , add 10 parts of water during stirring;

[0056] Step 3. The stirred mixture enters the QTY-15 vibration block forming machine through the belt conveyor, and is formed by cloth, vibration, and pressing at room temperature; the block forming time is 60 seconds per board, an...

Embodiment 2

[0059] Step 1. Take 20 parts of the Yellow River silt and stack it for 6 months, transport it to the mud storage, mix it with 30 parts of the Yellow River cement, and 10 parts of fly ash according to the ratio of parts by weight, then remove weeds, grass roots and other sundries. Homogenize to obtain mixture 1;

[0060] Step 2: Take coal gangue according to the ratio of parts by weight and pulverize it with a hammer mill until the particle size is ≤2.5mm, send it into the box feeder with a forklift, measure it, and transport it together with the mixture 1 to a strong mixer for 8 minutes by a belt conveyor , add 5 parts of water during stirring;

[0061] Step 3. The stirred mixture enters the QTY-15 vibration block forming machine through the belt conveyor, and is formed by cloth, vibration, and pressing at room temperature; the block forming time is 30 seconds per board, and the block is sent to the drying room after forming , the temperature is 90°C, the blocks are dried in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com