Extraction dechlorination method for petroleum unpolymerized C5

A dechlorination and petroleum technology, used in extraction purification/separation, distillation purification/separation, etc., can solve the problems of high safety protection level, catalyst poisoning and deactivation, and high process pressure, so as to improve the utilization rate of raw materials and reduce dechlorination. The effect of low cost and equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

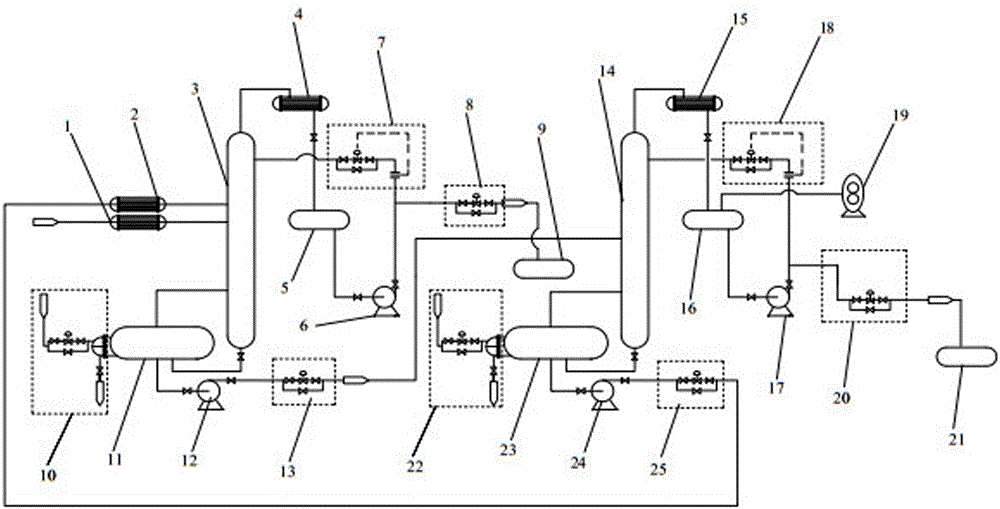

[0033] A method for extracting and dechlorinating petroleum unpolymerized C5, including the following steps:

[0034] Step (1): Turn on the circulating water of condenser I;

[0035] Step (2): The unpolymerized C5 raw material passes through a preheater to control its temperature to 40°C, and enters the extraction tower from 60 plates at the bottom. The DMF extractant passes through a heat exchanger to control its temperature to 80°C. 80 plates enter the extraction tower, and the feed mass ratio of unpolymerized C5 raw material to DMF extractant is 1:1;

[0036] Step (3): When the liquid level of the reboiler I communicating with the bottom of the extraction tower described in step (2) rises to 30%, turn on the high-temperature steam heating system I of the reboiler I and control its temperature to 80°C, The dechlorinated and unpolymerized C5 in the extraction tower is discharged from the top of the tower, condensed by condenser I, and enters the collection tank I. When the liquid l...

Embodiment 2

[0041] A method for extraction and dechlorination of petroleum unpolymerized C5, including the following steps:

[0042] Step (1): Turn on the circulating water of condenser I;

[0043] Step (2): The unpolymerized C5 raw material passes through a preheater to control its temperature to 80°C, and enters the extraction tower from 45 plates at the bottom. The DMF extractant passes through a heat exchanger to control its temperature to 60°C. 60 plates enter the extraction tower, and the feed mass ratio of the unpolymerized C5 raw material and DMF extractant into the tower is 1:10;

[0044] Step (3): When the liquid level of the reboiler I connected to the bottom of the extraction tower described in step (2) rises to 50%, turn on the high-temperature steam heating system I of the reboiler I and control its temperature to 130°C, The dechlorinated and unpolymerized C5 in the extraction tower is discharged from the top of the tower, is condensed by condenser I, and enters the collecting tan...

Embodiment 3

[0049] A method for extraction and dechlorination of petroleum unpolymerized C5, including the following steps:

[0050] Step (1): Turn on the circulating water of condenser I;

[0051] Step (2): The unpolymerized C5 raw material passes through a preheater to control its temperature to 60°C, and enters the extraction tower from 52 plates at the bottom. The DMF extractant passes through a heat exchanger to control its temperature to 70°C. 70 plates enter the extraction tower, and the feed mass ratio of the unpolymerized C5 raw material to the DMF extractant in the tower is 1:5;

[0052] Step (3): When the liquid level of the reboiler I connected to the bottom of the extraction tower described in step (2) rises to 40%, turn on the high-temperature steam heating system I of the reboiler I and control its temperature to 100°C, The dechlorinated unpolymerized C5 in the extraction tower is discharged from the top of the tower, condensed by condenser I, and enters the collection tank I. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com