Pigment fast brilliant red BBC dispersion and preparation method therefor

A light-fast bright red and dispersion technology, applied in the field of pigments, can solve problems such as poor stability and poor dispersion, and achieve the effects of improving stability, improving dispersibility, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

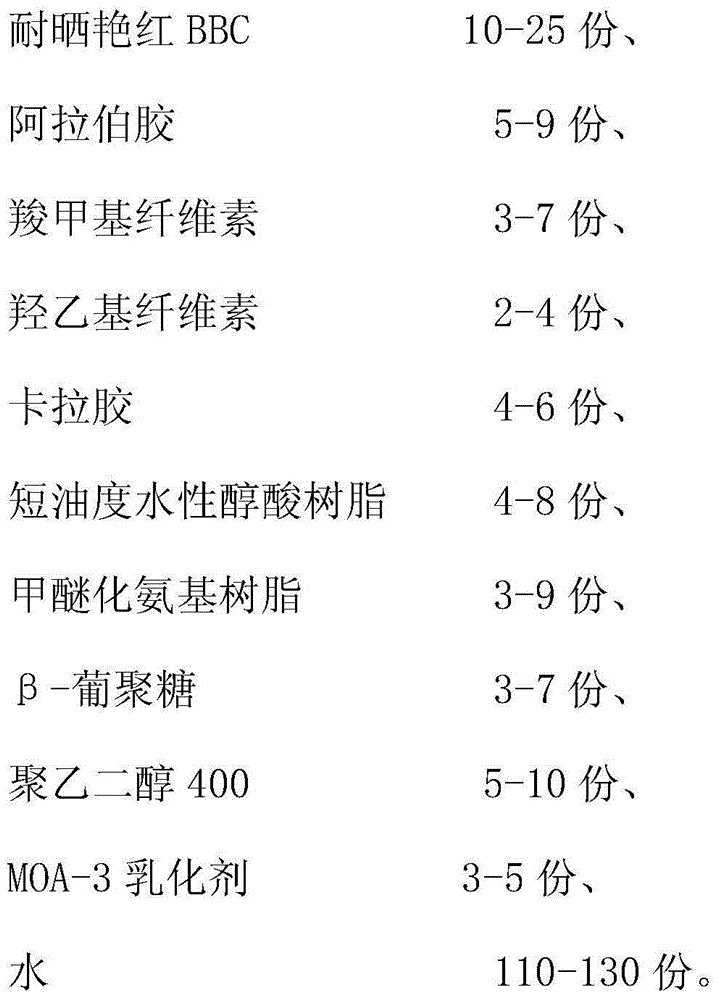

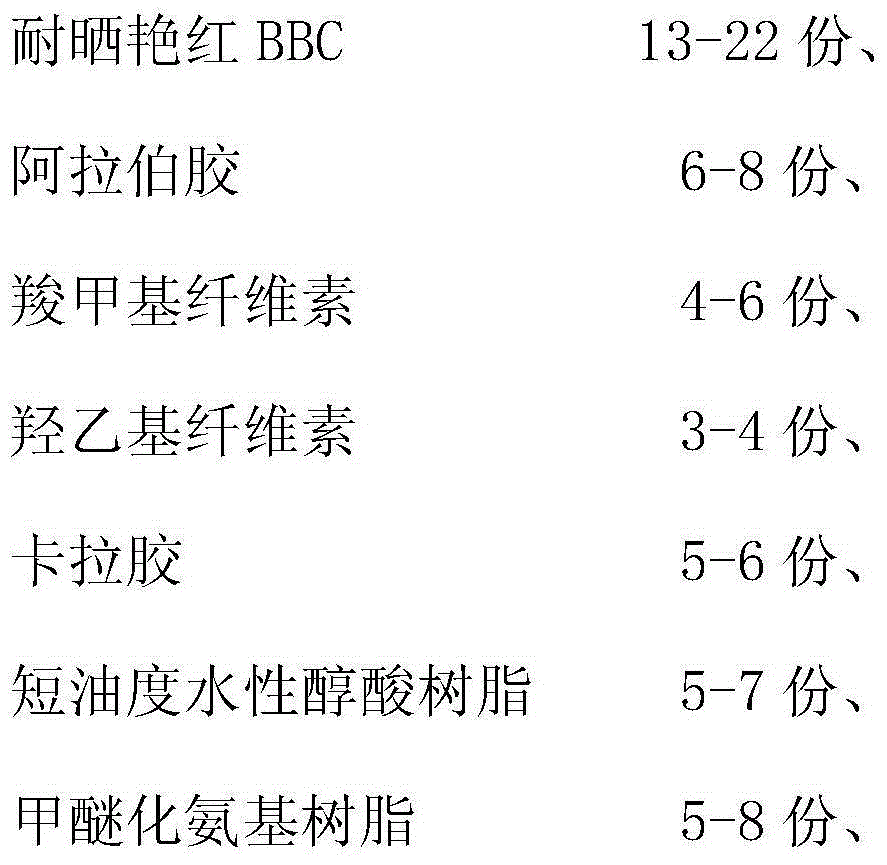

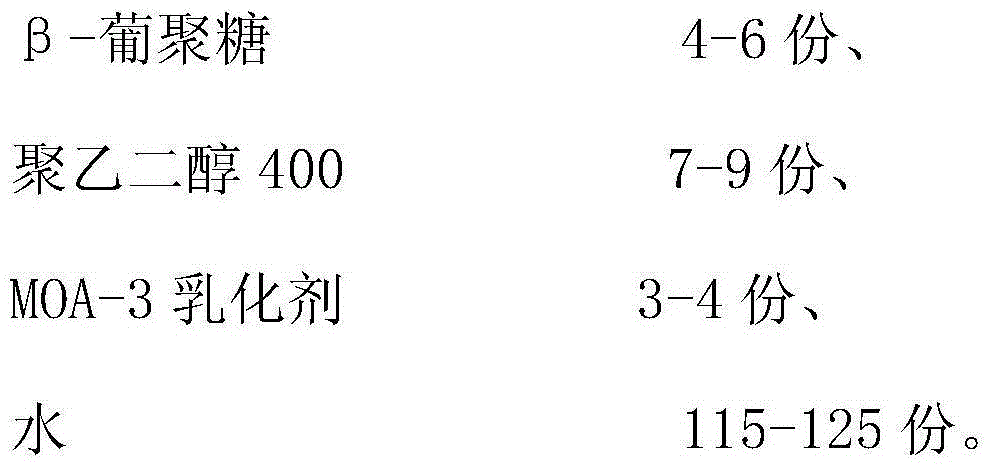

Method used

Image

Examples

Embodiment 1

[0019] (1) Take 25 parts of sunfast bright red BBC, 5 parts of gum arabic, 7 parts of carboxymethyl cellulose, 4 parts of hydroxyethyl cellulose, 4 parts of carrageenan, and 130 parts of water respectively by weight, and mix the above-mentioned various ingredients Put it into the stirred tank, mechanically stir, the stirring speed is 300rpm, and the stirring time is 20min;

[0020] (2) Take again by weight 8 parts of short-oil water-based alkyd resin, 3 parts of methyl etherified amino resin, 7 parts of β-glucan, 5 parts of polyethylene glycol 400, and 3 parts of MOA-3 emulsifier, Stir the above ingredients again, the stirring speed is 300rpm, and the stirring time is 10min;

[0021] (3) The dispersion stirred in the step (2) is then sheared with a shearing machine, the shearing speed is 6000r / min, and the shearing time is 35min. After shearing, it is sealed and stored, and it is a Brilliant Red BBC dispersion.

Embodiment 2

[0023] (1) Take 10 parts of sunfast bright red BBC, 9 parts of gum arabic, 3 parts of carboxymethyl cellulose, 2 parts of hydroxyethyl cellulose, 6 parts of carrageenan, and 110 parts of water respectively by weight, and mix the above-mentioned various ingredients Put it into the stirred tank, mechanically stir, the stirring speed is 100rpm, and the stirring time is 50min;

[0024] (2) Take 4 parts of short-oil water-based alkyd resin, 9 parts of methyl etherified amino resin, 3 parts of β-glucan, 10 parts of polyethylene glycol 400, and 5 parts of MOA-3 emulsifier by weight, Stir the above ingredients again, the stirring speed is 100rpm, and the stirring time is 30min;

[0025] (3) The dispersion stirred in the step (2) is then sheared with a shearing machine, the shearing speed is 4000r / min, and the shearing time is 15min. After shearing, it is sealed and stored, and it is a Brilliant Red BBC dispersion.

Embodiment 3

[0027] (1) Take 22 parts of sunfast bright red BBC, 8 parts of gum arabic, 6 parts of carboxymethyl cellulose, 4 parts of hydroxyethyl cellulose, 5 parts of carrageenan, and 115 parts of water respectively by weight, and mix the above-mentioned various ingredients Put it into the stirred tank, mechanically stir, the stirring speed is 300rpm, and the stirring time is 20min;

[0028] (2) Take 5 parts of short-oil water-based alkyd resin, 8 parts of methyl etherified amino resin, 6 parts of β-glucan, 9 parts of polyethylene glycol 400, and 3 parts of MOA-3 emulsifier by weight, Stir the above ingredients again, the stirring speed is 300rpm, and the stirring time is 10min;

[0029] (3) The dispersion stirred in the step (2) is then sheared with a shearing machine, the shearing speed is 6000r / min, and the shearing time is 35min. After shearing, it is sealed and stored, and it is a Brilliant Red BBC dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com