Waterproof and breathable paper diaper base membrane and manufacturing method thereof

A waterproof breathable, waterproof breathable layer technology, applied in textiles and papermaking, medical science, fabric surface trimming, etc., can solve the problems of low production technology, the bottom film depends on foreign imports, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

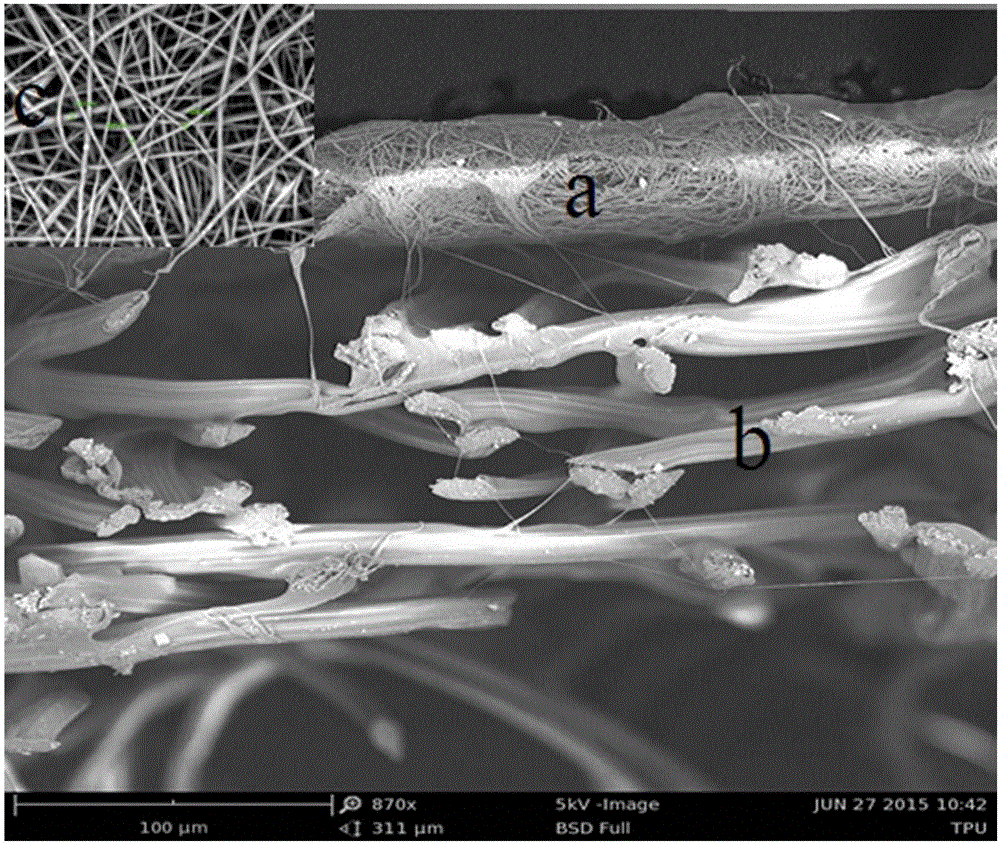

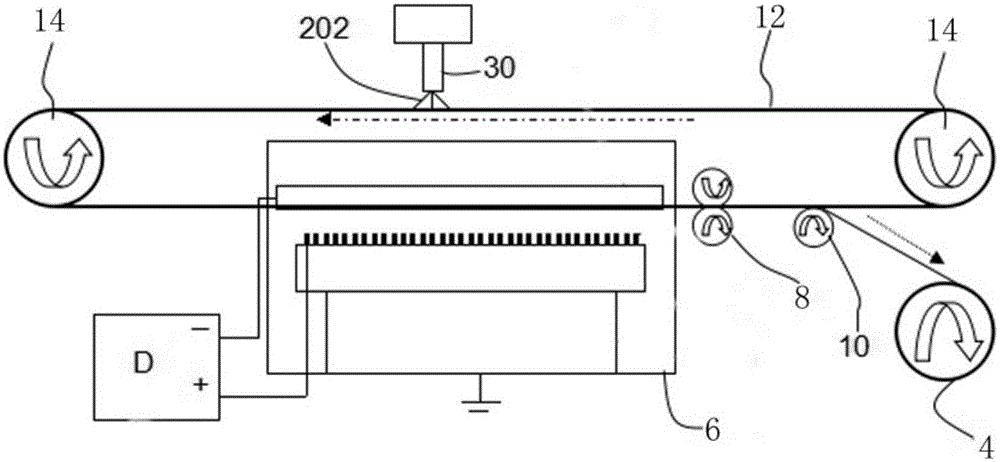

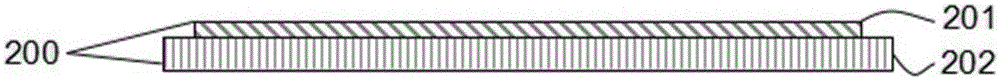

[0033] Such as figure 1 , 2, 3, a waterproof and breathable diaper bottom film is disclosed in this embodiment, including a nanofiber accumulation layer 201 formed by high-voltage electrospinning and a melt-blown non-woven fiber layer 202, wherein the melt-blown non-woven fiber Layer 202 is a non-woven fiber layer with an air permeability of 100-700 CFM and a thickness of 5-20 GSM.

[0034] The method for preparing above-mentioned base film comprises the following steps:

[0035] 1) Prepare a non-woven fabric fiber layer with an air permeability of 100-700CFM and a thickness of 5-20GSM: select a skin-friendly polymer resin, wherein the skin-friendly polymer resin is polypropylene resin (PP), polyethylene terephthalate One of ethylene glycol formate (PET) and polyamide resin (PA), the skin-friendly polymer resin is added to the melt-blown spinning mechanism 30 as a raw material, and the conveying roller 14 drives the conveyor belt 12 to move, while the melt-blown spinning Th...

Embodiment 2

[0042] Embodiment 2 differs from Embodiment 1 only in that the components of the hydrophobic resin and the organic solvent are different.

[0043] Disclosed in this embodiment is a waterproof and breathable diaper bottom film, comprising a nanofiber accumulation layer 201 and a melt-blown non-woven fabric fiber layer 202 formed by spinning composites, wherein the air permeability of the melt-blown non-woven fabric fiber layer 202 is 100~700CFM, non-woven fiber layer with a thickness of 5~20GSM.

[0044] The method for preparing above-mentioned base film comprises the following steps:

[0045] 1) Prepare a non-woven fabric fiber layer with an air permeability of 100-700CFM and a thickness of 5-20GSM: select a skin-friendly polymer resin, wherein the skin-friendly polymer resin is polypropylene resin (PP), polyethylene terephthalate One of ethylene glycol formate (PET) and polyamide resin (PA), the skin-friendly polymer resin is added to the melt-blown spinning mechanism 30 as ...

Embodiment 3

[0052] The difference between Example 3 and Example 1 is: the composition of the non-woven fiber layer is different, and the spinning parameters of the multi-nozzle high-voltage electrostatic spinning equipment are different.

[0053] Such as figure 1 , 4 , 5, this embodiment discloses a waterproof and breathable paper diaper bottom film, including a nanofiber accumulation layer 101 and a non-woven fiber layer 102 composited by high-voltage electrospinning, wherein the non-woven fiber layer 102 The air permeability is 100~700CFM, and the thickness is 5~20GSM.

[0054] The method for preparing above-mentioned base film comprises the following steps:

[0055] 1) Select one of the easily degradable and hygroscopic cellulose fibers, regenerated cellulose fibers, and chitosan fibers as a material to make a non-woven fiber layer with a thickness of 5-20GSM, and carry out the non-woven fiber layer Embossing or printing treatment, the pattern representing the company culture is pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com