Novel levelling agent for dyeing pure cotton and dyeing method thereof

A dyeing method and leveling agent technology, applied in dyeing methods, textiles and papermaking, etc., to achieve the effects of shortening dyeing time, good market promotion value, and increasing dyeing percentage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

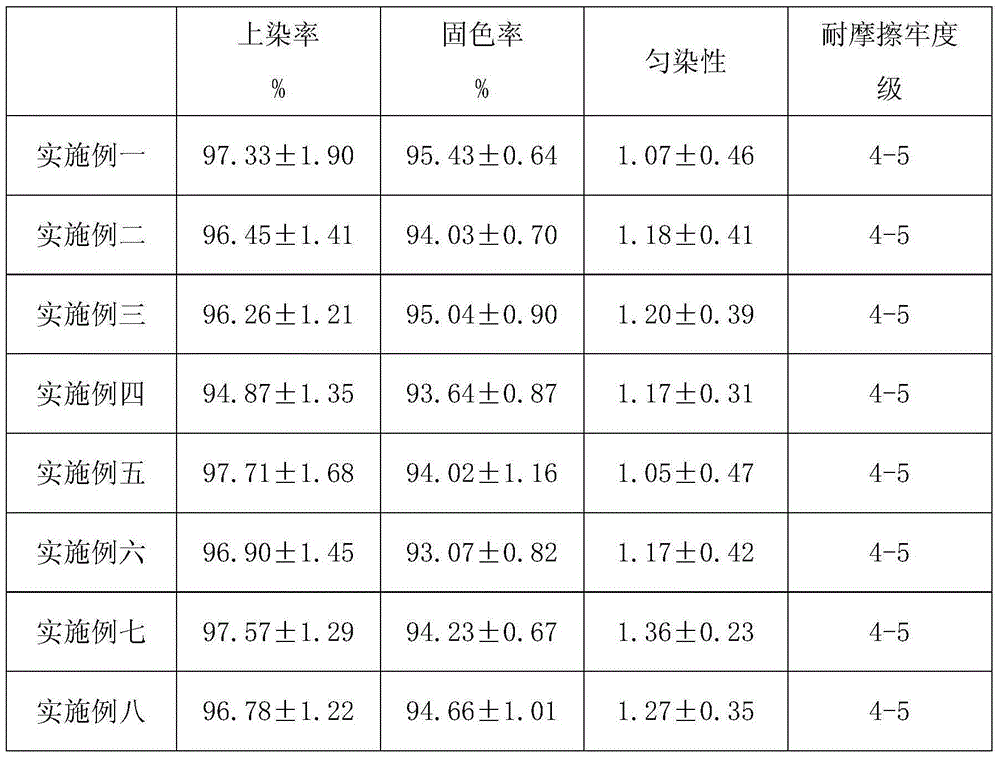

Examples

Embodiment 1

[0027] A novel leveling agent for pure cotton dyeing, comprising the following components by weight percentage:

[0028] Methylene bis-naphthalene sulfonate 5%, lignosulfonate 7%, anhydrous sodium sulfate 2%, carboxymethyl cellulose 1%, chondroitin sulfate 0.5%, triethanolamine 0.1%, and the balance is water.

[0029] Its dyeing method comprises the following steps:

[0030] Step 1: Mix and soak pure cotton fabric with water at a bath ratio of 1:10, add leveling agent and dye in turn and stir evenly, then adjust the pH to 5.0 with glacial acetic acid, the amount of leveling agent and dye added is 100% for pure cotton fabric 1% and 3% of dry weight mass;

[0031] Step 2: Stir and dye at 35°C for 30 minutes, then raise the temperature at 3°C per minute to 80°C and keep it warm for 10 minutes, then take it out and wash it with water for 10 minutes after cooling down to 35°C;

[0032] Step 3: Put the pure cotton fabric into the dye vat again, raise the temperature at 1°C per m...

Embodiment 2

[0034] A novel leveling agent for pure cotton dyeing, comprising the following components by weight percentage:

[0035] Methylene bis-naphthalene sulfonate 9%, lignosulfonate 10%, anhydrous sodium sulfate 6%, carboxymethyl cellulose 3%, chondroitin sulfate 1%, triethanolamine 0.3%, and the balance is water.

[0036] Its dyeing method comprises the following steps:

[0037] Step 1: Mix and soak pure cotton fabric with water at a bath ratio of 1:18, add leveling agent and dye in turn and stir evenly, then adjust the pH to 5.5 with glacial acetic acid, the amount of leveling agent and dye added is 100% for pure cotton fabric 3% and 10% of dry weight mass;

[0038] Step 2: Stir and dye at 35°C for 50 minutes, then raise the temperature at 3°C per minute to 85°C and keep it warm for 20 minutes, then take it out and wash it with water for 15 minutes after cooling down to 40°C;

[0039] Step 3: Put the pure cotton fabric into the dye vat again, raise the temperature at 1°C per m...

Embodiment 3

[0041] A novel leveling agent for pure cotton dyeing, comprising the following components by weight percentage:

[0042] Methylene bis-naphthalene sulfonate 5%, lignosulfonate 10%, anhydrous sodium sulfate 2%, carboxymethyl cellulose 3%, chondroitin sulfate 0.5%, triethanolamine 0.3%, and the balance is water.

[0043] Its dyeing method comprises the following steps:

[0044] Step 1: Mix and soak pure cotton fabric with water at a bath ratio of 1:10, add leveling agent and dye in turn and stir evenly, then adjust the pH to 5.5 with glacial acetic acid, the amount of leveling agent and dye added is 100% for pure cotton fabric 1% and 10% of dry weight mass;

[0045] Step 2: Stir and dye at 35°C for 30 minutes, then raise the temperature at 3°C per minute to 85°C and keep it warm for 10 minutes, then take it out and wash it with water for 15 minutes after cooling down to 40°C;

[0046]Step 3: Put the pure cotton fabric into the dye vat again, raise the temperature at 1°C per ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com