Construction technology of movable flexible floating type breakwater

A floating breakwater and construction technology technology, applied in the direction of breakwaters, jetties, embankments, etc., can solve the problems of poor fast retractable movement performance, lack of a construction process system, high requirements for manufacturing and installation, and achieve good wave dissipation effect, Good anti-wave effect and convenient construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

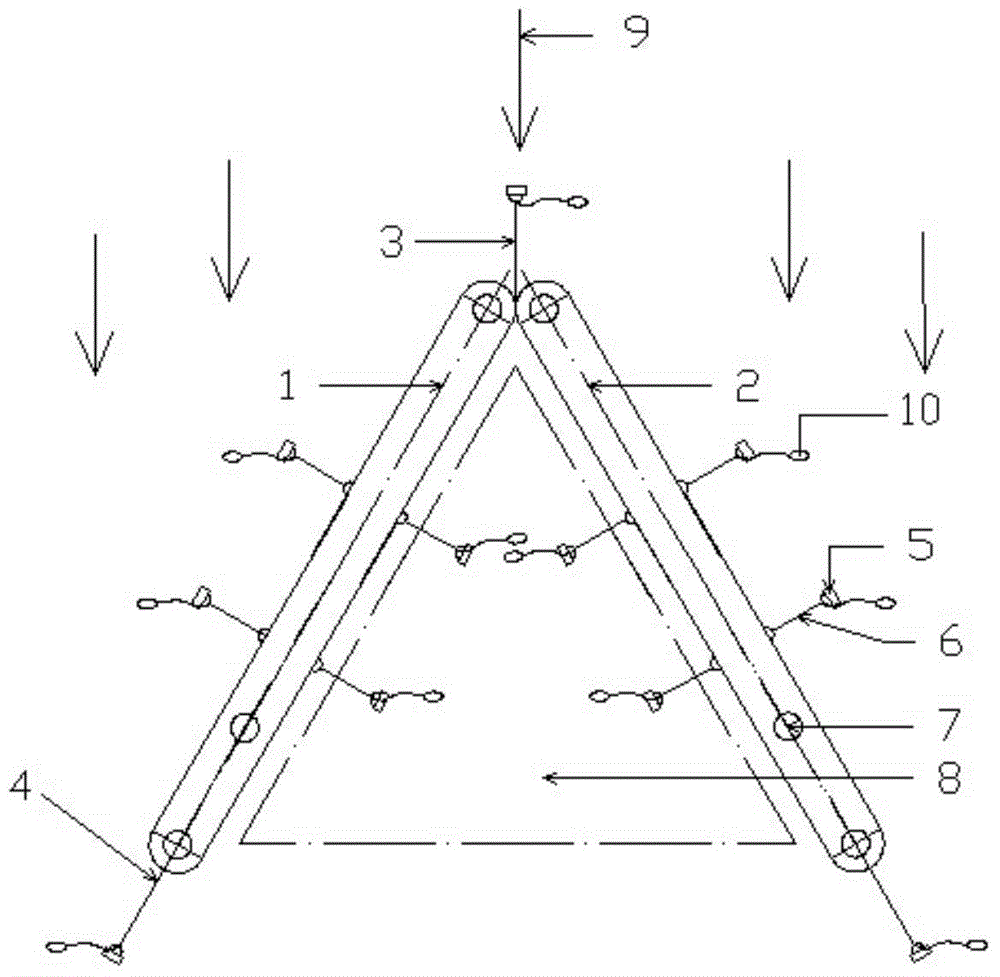

[0034] The following is a description of the construction of a V-shaped breakwater as an example.

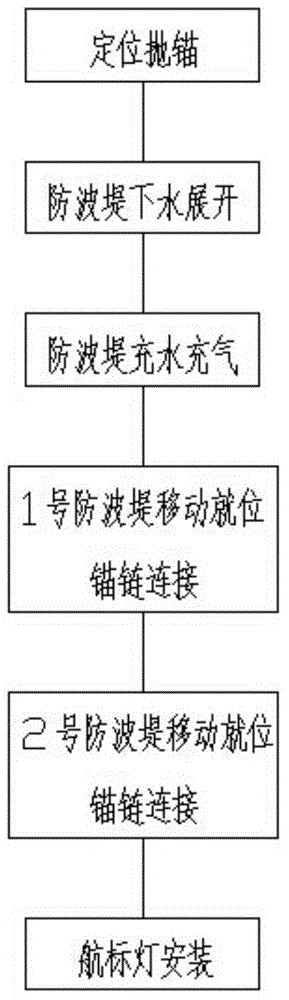

[0035] This embodiment adopts the following specific steps:

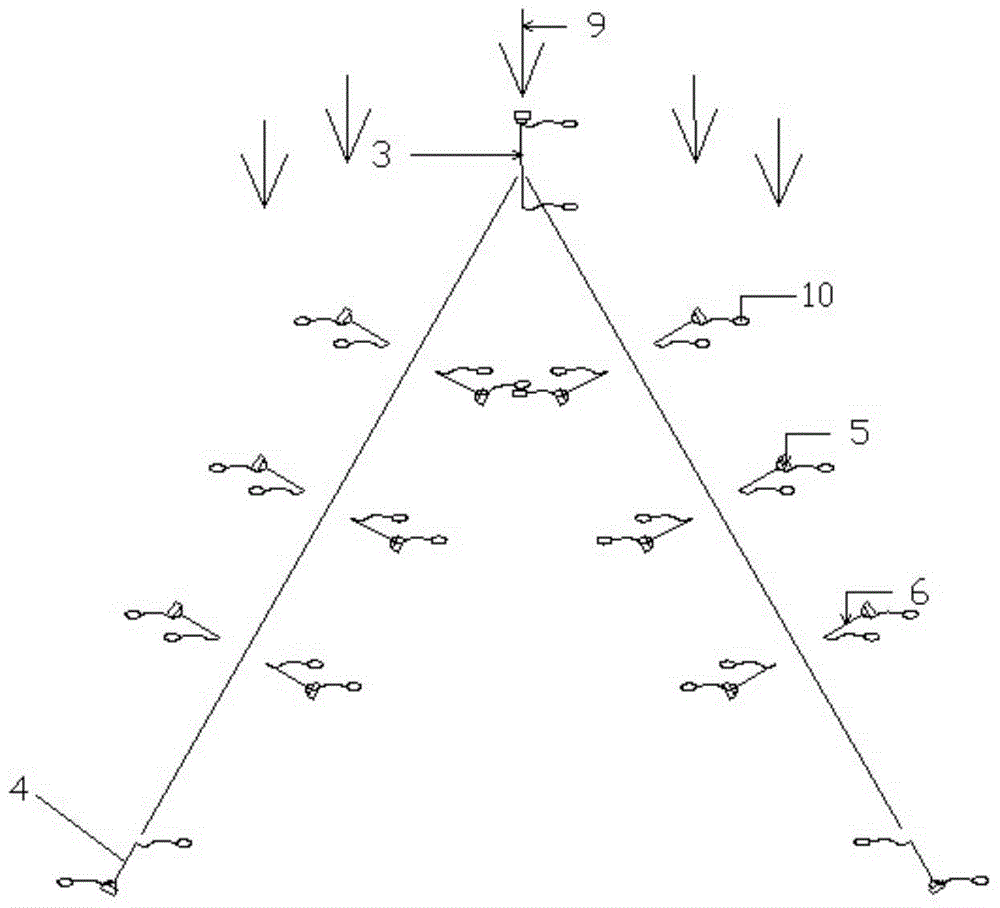

[0036] (1) Determine the anchoring coordinates on the sea surface according to the design drawings. The determined anchoring coordinates form a V-shaped distribution. Each anchoring coordinate is distributed on both sides and both ends of the water area where the breakwater is to be installed. The included angle becomes 50°-70°, then the anchor is connected with the anchor chain, and the float 10 is connected respectively on the anchor and the anchor chain, and then the anchor is thrown at the coordinates determined on the sea surface. In this embodiment, the V-shaped included angle is preferably 60°;

[0037] (2) Use a crane to hoist the head of No. 1 breakwater 1 folded on the retractable rack and place it on the water surface, and hang the temporary rope prepared in advance on the head on another tugboat for tract...

Embodiment 2

[0047] According to the conditions of the sea waves and the needs of the actual wave dissipation effect, on the basis of the above-mentioned embodiment 1, repeat the above steps, and arrange at least one layer of breakwaters parallel to them outside the No. 1 breakwater and No. 2 breakwater, which can effectively play a role in multi-stage dissipation. The role of waves.

[0048] It should be noted that the above-mentioned embodiment takes the V-shaped breakwater as an example. According to specific sea conditions and operation requirements, when determining the anchor coordinates, the anchor coordinates can also be arranged in a straight line, circular arc, or ring, or multiple Various shapes are combined to meet the needs of operation and anti-wave.

Embodiment 3

[0050] According to the conditions of the sea waves and the needs of the actual wave dissipation effect, on the basis of the above-mentioned embodiment 1 and embodiment 2, multiple breakwaters can be connected end-to-end on both sides of the V-shaped structure to increase the overall length of the breakwater, such as Figure 5 Shown is a schematic diagram of the end-to-end connection of two breakwaters on each side.

[0051]In addition, according to the conditions of the sea waves and the needs of the actual wave dissipation effect, when determining the anchor coordinates, the anchor coordinates can also be formed into a straight line, a circular arc, a ring, or a combination of multiple types.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com