A semi-automatic building method

A semi-automatic, construction technology, applied in the processing of building materials, construction, building components, etc., can solve the problems of difficult level, short project cycle requirements, difficult quality assurance, etc., to achieve low manpower, shorten construction period, and ensure construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

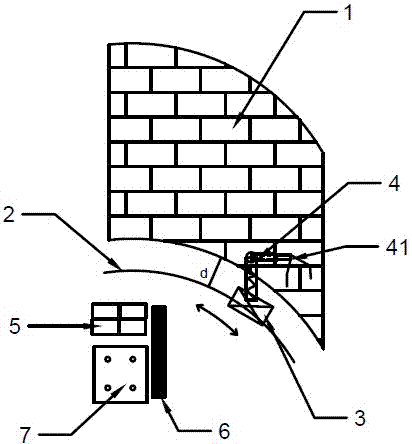

[0051] Embodiment 1: as image 3 As shown, the main body of the building is circular and the blocks used are slightly arc-shaped. The laid slide rail 2a is a circular slide rail. Table 3 and the robotic arm 4 assembled on top of it. Of course, only one lifting slide table 3 and the mechanical arm 4 assembled on the top thereof can be set, and it can move circularly along the slide rail. What needs to be mentioned here is that there is an air shaft with a diameter of 1.2-2 meters in the center of the circular building, and multiple elevator shafts are set around the air shaft, and then aisles with a width of 3-6 meters are set at the exits of each elevator, and then to Spread out a circle (about 20 households) of public activity places or rooms, which can change the disadvantages of existing multi-high-rise residential buildings without neighbors. The circular building has strong anti-seismic performance, and each floor can float up and down between the surrounding ring beam ...

Embodiment 2

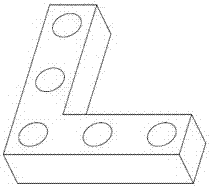

[0052] Embodiment 2: as Figure 4 As shown, there are several 25m2 2 For the following chambers, slide rails 2b are laid along the line connecting the center points (A, B, C, D) of each chamber, and one or several elevators driven to guide and translate along the slide rails 2b are loaded on the slide rails 2b. The sliding table 3 and the mechanical arm 4 assembled on the top thereof work independently in each chamber or traverse the work point by point. Partial walls built by masonry such as Figure 10 shown.

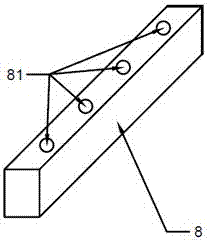

[0053] The setting method of the slide rail 2 in the above-mentioned embodiment 1 and embodiment 2 is to enable the lifting slide table 3 on the slide rail 2 to run smoothly during the masonry process until the wall laying is completed at each station. At the same time, in order to better respond to different wall construction requirements, the mechanical arm 4 assembled on the top of the lifting slide table 3 should be set to be telescopic. When the main body of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com