Equipment and method for precise guidance and docking of ground holes in coal mine areas and targets in underground roadways

An underground tunnel and target technology, which is used in directional drilling, earth-moving drilling, wellbore/well components, etc., can solve the problems of low docking accuracy, high target hit rate, small positioning error, etc. The effect of high target rate and small positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

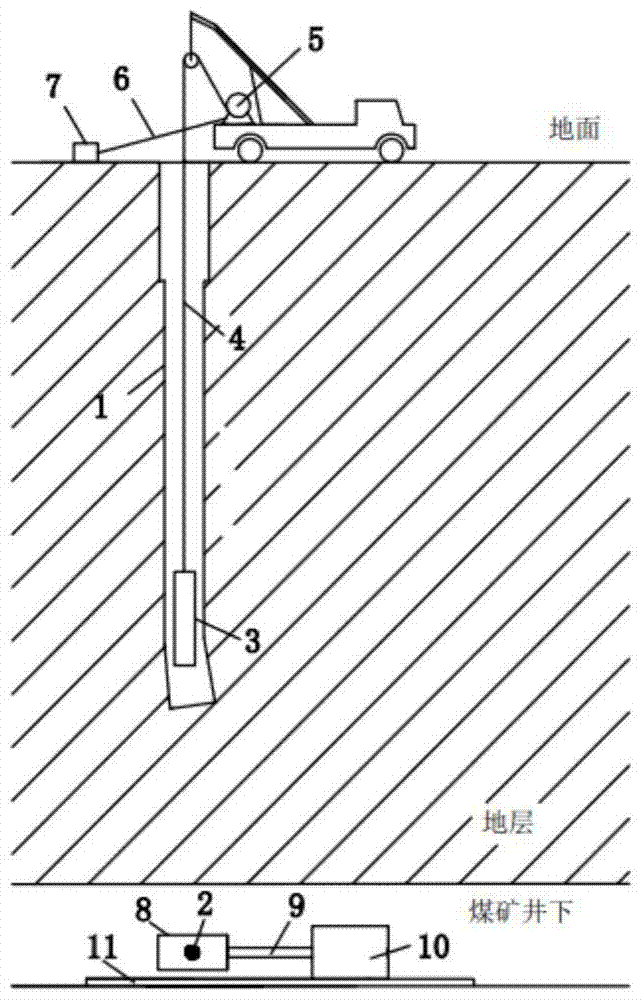

[0035] see figure 1 , which shows the precise guidance and docking equipment of the present invention for the ground hole in the coal mine area and the target point in the underground roadway.

[0036] The precise guidance and docking equipment for the ground hole in the coal mine area and the target point in the underground roadway at least includes ground equipment and underground equipment. The ground equipment includes at least a guiding measurement probe 3 and a hole signal processor 7. Section 8, connecting rod 9, rotary feed mechanism 10 and guide rail 11.

[0037] Wherein, the guide measuring probe 3 can be cylindrical, and contains an alternating magnetic field sensor with a detection range ≥ 40m to detect the alternating magnetic field parameters of the strong magnetic short joint 8. The guide measuring probe 3 It also contains an acceleration sensor and a fluxgate sensor to detect the position state parameters of the guiding measuring probe 3, and the guiding measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com