Coated gate valve

A clad, gate valve technology, applied in valve details, valve device, valve shell structure, etc., can solve problems such as short life, difficult installation, and short valve body orders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

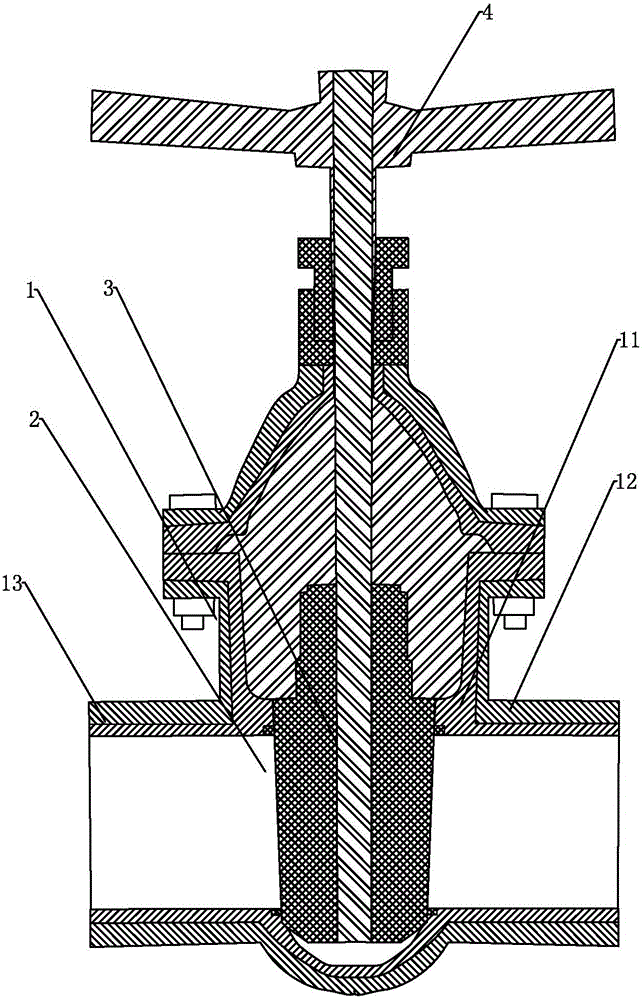

[0018] As shown in the figure, a clad gate valve includes a valve body 1, a fluid channel 2 is provided in the valve body 1, and a gate 3 that can block the fluid channel 2 is provided on the valve body 1. 1 is provided with a handle 4 connected to the gate 3, and the gate 3 is driven to move up and down by rotating the handle 4, thereby realizing the function of the gate 3 blocking the fluid channel 2 and closing the valve. Both ends of the fluid channel 2 are extended outwards with external connecting pipes 13 fixedly connected with other pipes. The valve body 1 includes a stainless steel layer 11 placed in the inner layer and a plastic layer 12 covering the stainless steel layer 11 by injection molding. Because the valve body 1 adopts the stainless steel material layer placed in the inner layer and the plastic layer covering the stainless steel material laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com