High-efficiency and energy-saving vertical sintering machine

A high-efficiency energy-saving, sintering machine technology, applied in the direction of dryers, furnace types, furnaces, etc., can solve the problems of low ore pre-reduction rate, continuous ignition of gas, difficult collection and treatment of smoke and dust, etc., to achieve good pre-return effect and equipment The effect of simple structure and high pre-reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

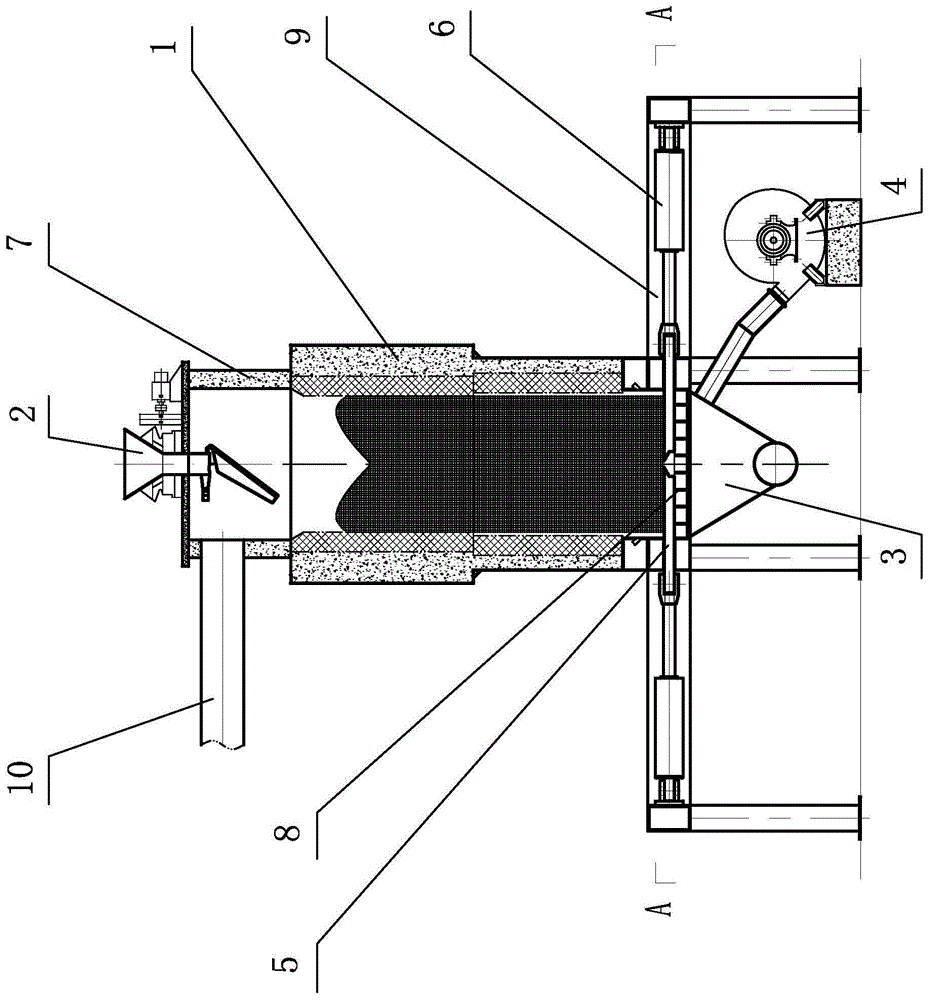

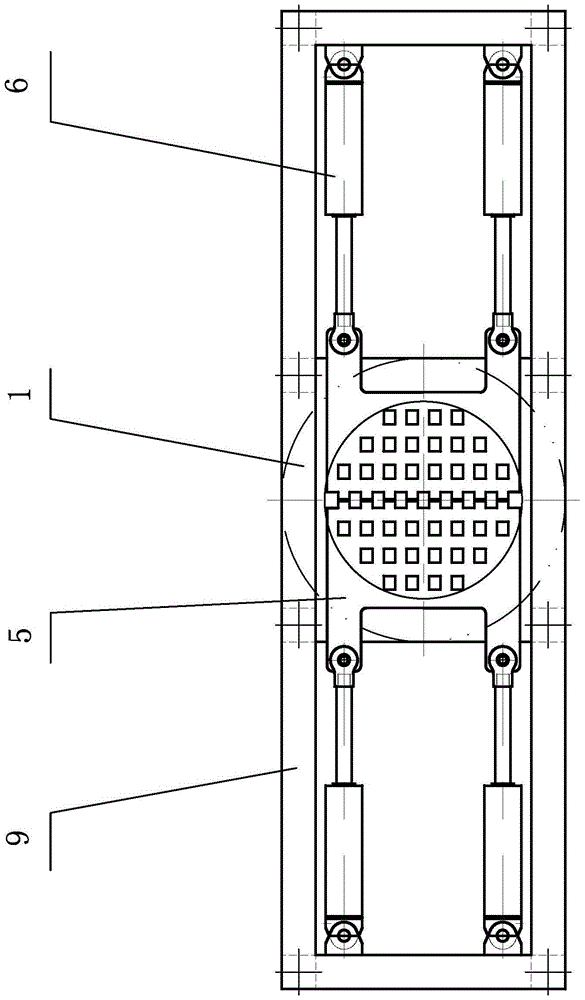

[0026] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0027] The high-efficiency energy-saving vertical sintering machine of the present invention, its main body is a furnace body 1 with a vertical structure, the inner wall of the furnace body is built with refractory bricks to form a furnace, and an igniter is arranged in the furnace, and the furnace body 1 is supported by a furnace frame 9 On site, a furnace cover 7 is built on the top of the furnace body 1 (i.e., a feed port), the top of the furnace cover 7 is placed with a feed bin 2, and the smoke outlet on the side of the furnace cover 7 is connected to a flue 10, and the flue 10 communicates with the dust collector, the unloading bin 3 is arranged below the lower opening (i.e., the discharge port) of the furnace body 1 in the furnace frame 9 and communicates with the discharge port, and the discharge port of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com