Crop row detection sensor for row operation of stalk crops

A technology for detecting sensors and crop rows, which is applied in the direction of instruments, measuring devices, surveying and navigation, etc., can solve the problems of greater influence on job quality proficiency, unstable job quality, high labor intensity, etc. The effect of improving the quality of operation and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order for those skilled in the art to better understand the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the following is only exemplary and does not limit the protection scope of the present invention.

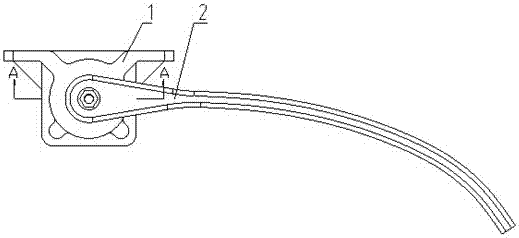

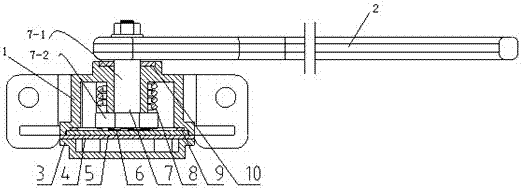

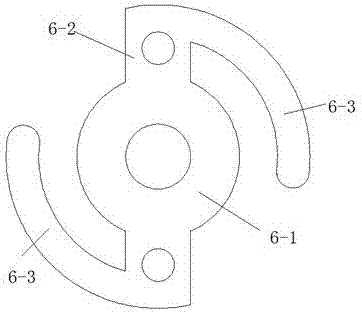

[0029] A crop row detection sensor for row-to-row operation of stalk crops, including a housing and a touch assembly; the housing includes an upper housing 1 and a lower housing 3 that are detachably connected as one by bolts, and the upper housing 1 and the installation The front end of the grain divider connected to the working machine is detachably connected by bolts, and a gasket 4 is provided between the upper casing 1 and the lower casing 3; the touch assembly includes the rotor 7, the moving piece 6, the fixed piece 5 and the opposite row Rod 2, wherein the rotor 7 includes a rotating shaft 7-1 and a base 7-2, the rotating shaft 7-1 is hingedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com