Ceramic pressure sensor and installing method thereof

A technology of a pressure sensor and an installation method, which is applied to the measurement of fluid pressure by changing ohmic resistance and the measurement of the property force of piezoelectric resistance materials, etc. The problem of high requirements on the processing size of the card slot, to achieve the effect of improving the use range and reliability, low product scrap rate, and strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

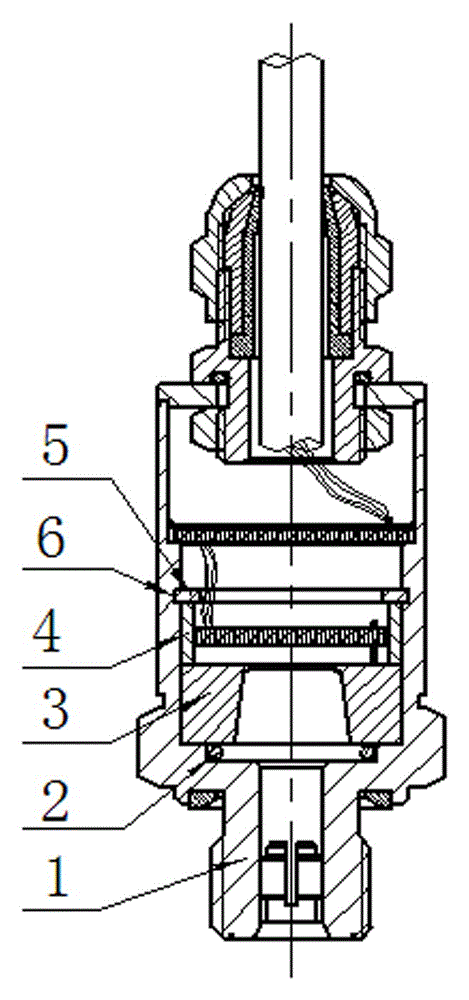

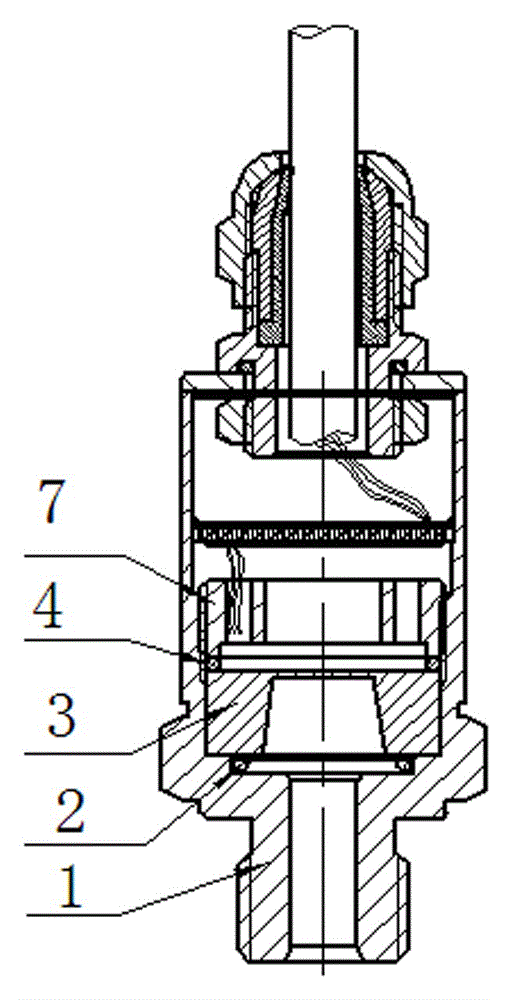

[0018] refer to figure 2 , image 3 , this embodiment includes a joint 1, an O-ring 2, a ceramic core 3 and a compression sleeve 4, the ceramic core 3 is packaged inside the joint 1, and an O-ring 2 is arranged between the ceramic core 3 and the joint 1 , A compression sleeve 4 is provided above the ceramic core 3, and also includes a locking buckle 7, and the compression sleeve 4 is placed between the ceramic core 3 and the locking buckle 7.

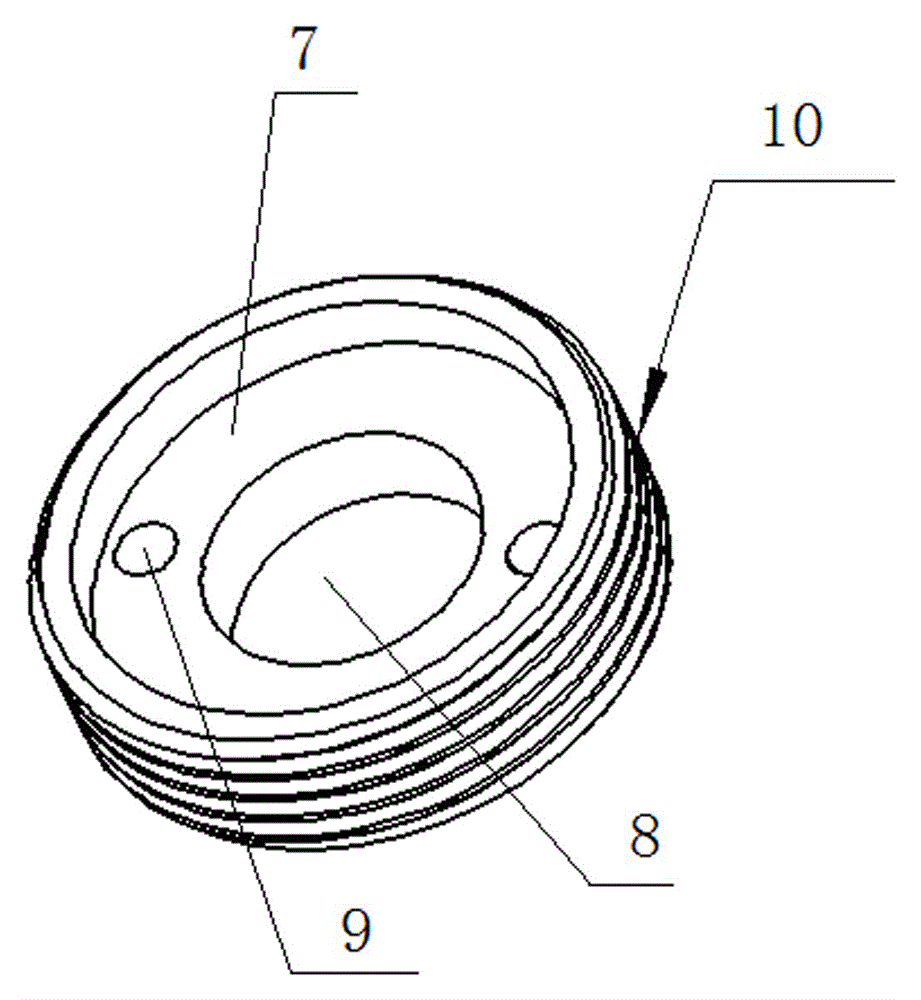

[0019] The outer wall of the locking buckle 7 is provided with an external thread 10, and the inner wall of the joint 1 is provided with an internal thread (not shown in the figure). The locking buckle 7 and the joint 1 are connected by threads, and the compression sleeve 4 and the Ceramic Core 3.

[0020] A through hole 8 is opened in the center of the locking buckle 7 , and circuit installation holes 9 are arranged on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com