Water chilling unit fault detection method based on improved FastICA

A fault detection and chiller technology, applied in the testing of refrigerators, refrigeration components, mechanical parts, etc., can solve problems such as few reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

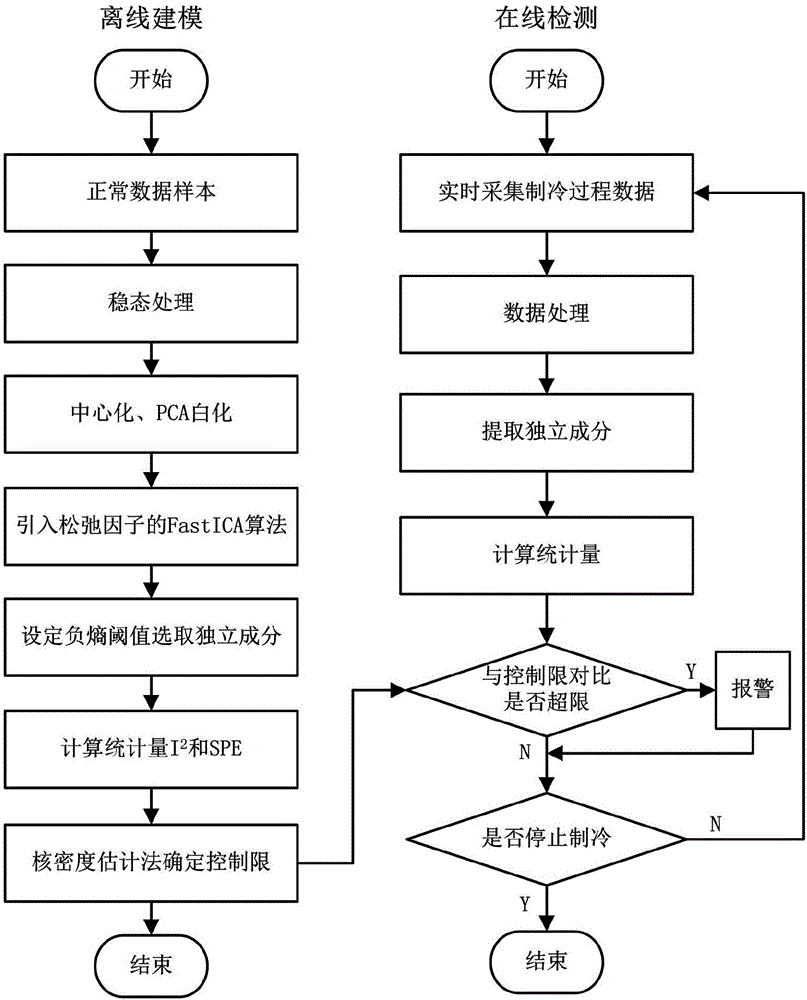

Method used

Image

Examples

Embodiment Construction

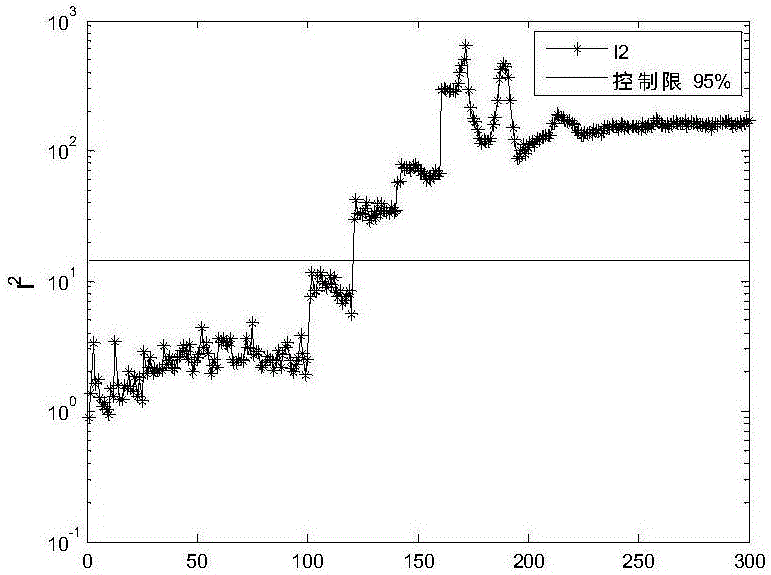

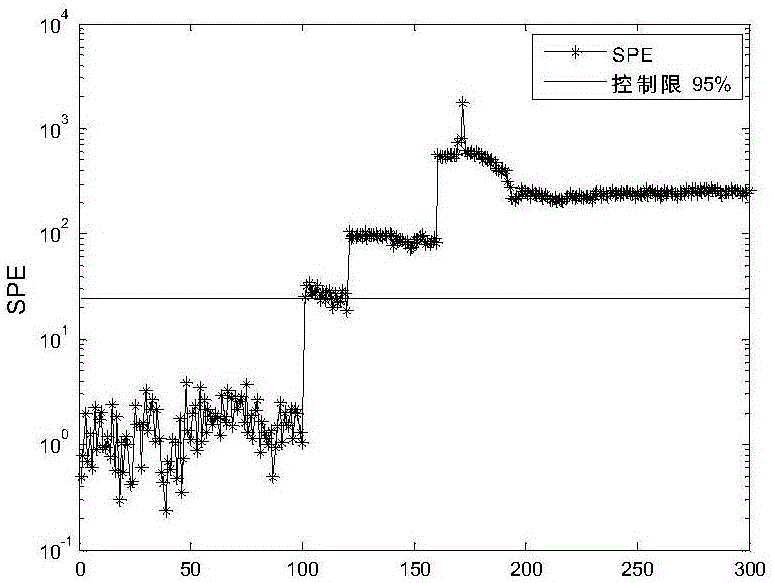

[0068] The experimental data in the present invention comes from ASHRAE1043-RP, and the experimental object is a 90-ton (about 316kW) centrifugal chiller. Under laboratory conditions, 7 typical gradual failures of chillers are simulated by a specially designed test bench. Each failure is tested under 27 working conditions, and a large amount of experimental data is collected. These data include data under normal operation and failure operation. In this paper, modeling and analysis of 7 kinds of gradual faults that are difficult to detect in chillers are carried out, as shown in Table 1.

[0069] Table 1 Failure Modes of Chillers

[0070]

[0071] The data collection interval is 10s, and 64 parameters are obtained, 16 of which are calculated in real time by VisSim software, and 48 are directly measured by sensors, including 29 temperature, 5 pressure, 5 flow, 7 valve positions, compressor power and Current, cooling coefficient of performance (COP), compressor efficiency, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com