A kind of neodymium iron boron magnetic material and preparation method thereof

A magnetic material, neodymium iron boron technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of low Curie temperature point, poor temperature characteristics, limited application fields, etc., to increase the Curie temperature, change Heat resistance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of neodymium iron boron magnetic material that the present embodiment provides, its composition weight percent is that light rare earth element is Nd and Ce, and Nd is 29%, and Ce is 0.5%, and heavy rare earth element is Dy and Er, and Dy is 4%, and Er Al is 0.8%, Al is 1%, Cu is 1%, Co is 2%, B is 0.3%, and the balance is Fe.

[0022] The preparation method of the above-mentioned NdFeB magnetic material comprises the following steps:

[0023] ① Ingredients, weighed according to the weight percentage of the composition of the NdFeB magnetic material, and set aside;

[0024] ②Smelting, first melt light rare earth elements at 1100°C, then add heavy rare earth elements to melt at 1400°C, then add Al, Cu, Co, B, Fe metal powder or alloys and melt at 1550°C, and then melt all the above melted After the components are fully mixed, they are cast and cooled to form NdFeB blocks;

[0025] ③ Hydrogen crushing, put the NdFeB blocks into the hydrogen crushing device to obt...

Embodiment 2

[0031] A kind of neodymium iron boron magnetic material that this embodiment provides, its composition weight percentage is that light rare earth element is Nd and La, and Nd is 28%, and La is 0.5%, and heavy rare earth element is Dy and Tb, and Dy is 3%, and Tb Al is 1%, Al is 2%, Cu is 2%, Co is 3%, B is 0.5%, and the balance is Fe. The preparation method of the above-mentioned NdFeB magnetic material is consistent with that of Example 1. The properties of the NdFeB magnetic material obtained in this embodiment are shown in Table 1.

Embodiment 3

[0033] A kind of NdFeB magnetic material provided by this embodiment, its composition weight percent is Nd, Pr and Gd as light rare earth elements, Nd is 28.5%, Pr is 0.5%, Gd is 0.5%, and heavy rare earth elements are Dy, Tb And Y, Dy is 3.5%, Tb is 0.5%, Y is 0.5%, Al is 1.5%, Cu is 1.5%, Co is 2.5%, B is 0.4%, and the balance is Fe. The preparation method of the above-mentioned NdFeB magnetic material is consistent with that of Example 1. The properties of the NdFeB magnetic material obtained in this embodiment are shown in Table 1.

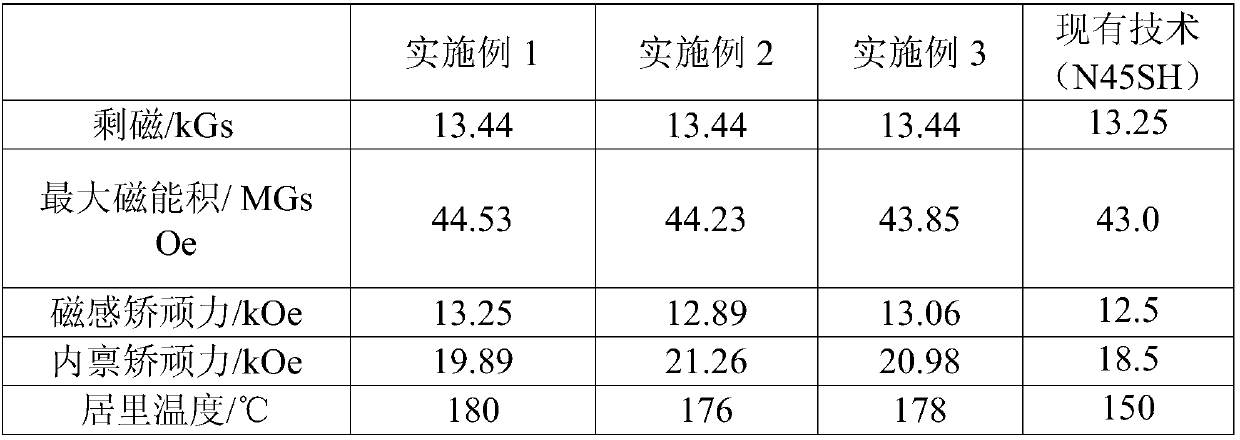

[0034] Table 1

[0035] NdFeB magnetic material performance table

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com