High-strength acrylate rubber material for automobiles, and preparation method and application thereof

An acrylate glue and acrylate technology, applied in the field of new materials, can solve problems such as poor low temperature resistance, poor mechanical properties, and limited applications, and achieve the effects of improving cold resistance and mechanical properties, meeting oil resistance, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

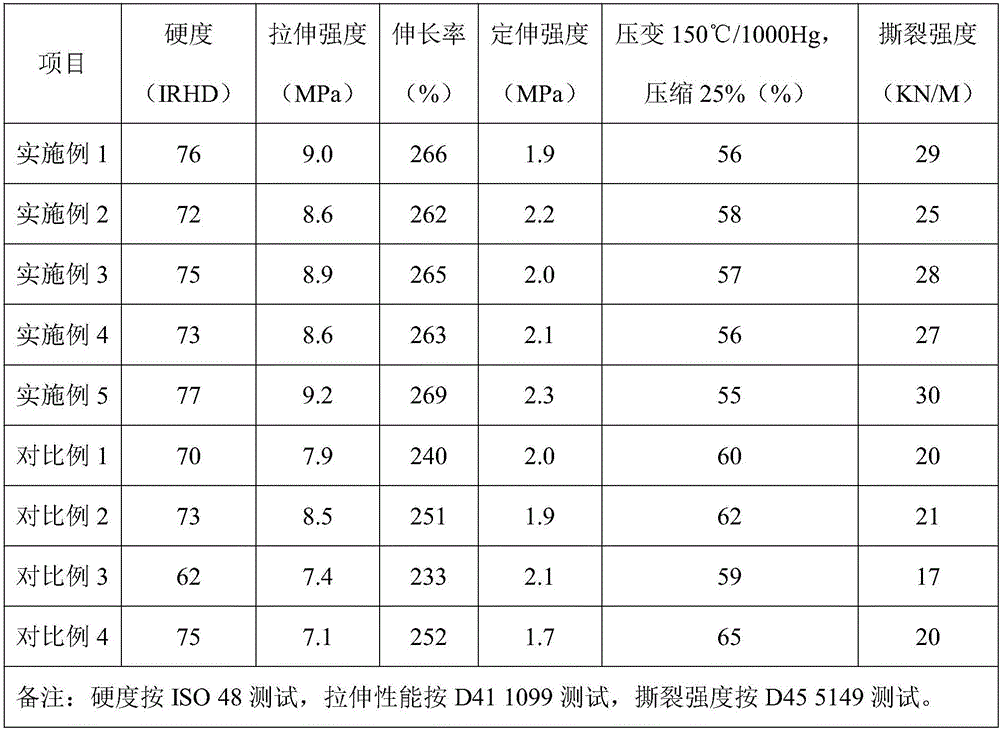

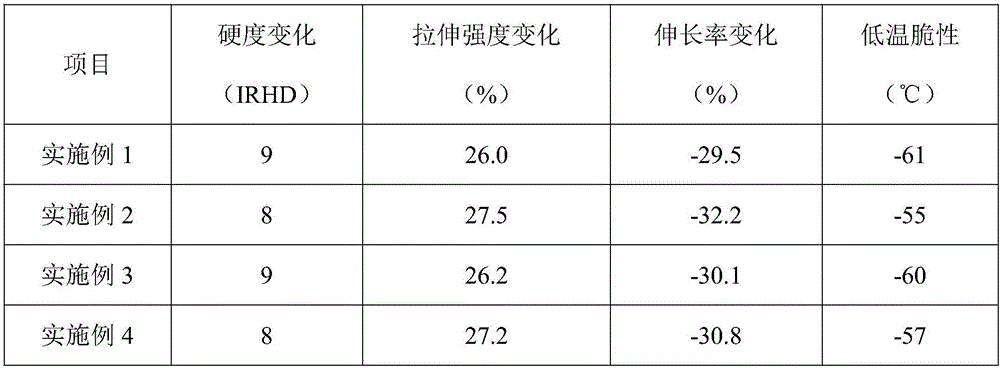

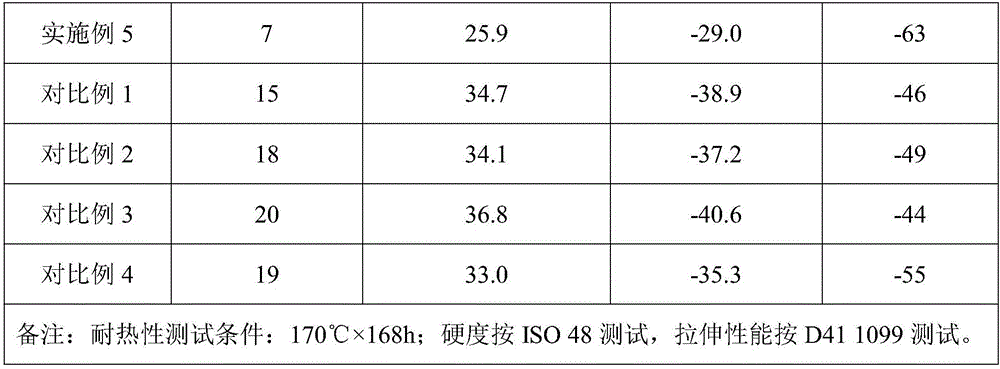

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a high-strength acrylate rubber compound for automobiles is composed of the following raw materials in parts by weight: 100 parts of acrylate rubber, 20 parts of silicic acid rubber, 14 parts of neoprene rubber, and high wear-resistant carbon black 24 parts, 10 parts of graphene, 1.2 parts of butyl stearate, 2.5 parts of tributyl citrate, 2.0 parts of aminosilane bonded silica gel, 11 parts of glass powder, 4452.2 parts of anti-aging agent, 1.5 parts of anti-aging agent IPPD, anti-aging agent 1.4 parts of NBC, 2.2 parts of zinc oxide, 1.0 parts of sodium oleate, 6.2 parts of sulfur, and 1.8 parts of accelerator DZ.

[0018] The preparation method of described high-strength acrylic sizing material for automobile comprises the following steps:

[0019] (1) Preheat high wear-resistant carbon black, graphene, glass powder, and aminosilane-bonded silica gel to 140°C, add butyl stearate, tributyl citrate, anti-aging agent 445, anti-...

Embodiment 2

[0024] In the embodiment of the present invention, a high-strength acrylate rubber compound for automobiles is composed of the following raw materials in parts by weight: 100 parts of acrylate rubber, 28 parts of silicic acid rubber, 8 parts of neoprene rubber, and high wear-resistant carbon black 30 parts, 6 parts of graphene, 1.6 parts of butyl stearate, 2.1 parts of tributyl citrate, 3.2 parts of aminosilane bonded silica gel, 7 parts of glass powder, 4452.6 parts of anti-aging agent, 1.0 parts of anti-aging agent IPPD, anti-aging agent 1.8 parts of NBC, 1.5 parts of zinc oxide, 1.3 parts of sodium oleate, 5.4 parts of sulfur, 2.4 parts of accelerator DZ.

[0025] The preparation method of the high-strength acrylic sizing material for automobiles is the same as in Example 1.

Embodiment 3

[0027] In the embodiment of the present invention, a high-strength acrylate rubber compound for automobiles is composed of the following raw materials in parts by weight: 100 parts of acrylate rubber, 22 parts of silicic acid rubber, 13 parts of neoprene rubber, and high wear-resistant carbon black 25 parts, 10 parts of graphene, 1.4 parts of butyl stearate, 2.4 parts of tributyl citrate, 2.6 parts of aminosilane bonded silica gel, 10 parts of glass powder, 4452.4 parts of anti-aging agent, 1.4 parts of anti-aging agent IPPD, anti-aging agent 1.5 parts of NBC, 2.0 parts of zinc oxide, 1.1 parts of sodium oleate, 6.0 parts of sulfur, 2.0 parts of accelerator DZ.

[0028] The preparation method of described high-strength acrylic sizing material for automobile comprises the following steps:

[0029] (1) Preheat high wear-resistant carbon black, graphene, glass powder, and aminosilane-bonded silica gel to 145°C, add butyl stearate, tributyl citrate, anti-aging agent 445, anti-agin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com