Composite high voltage insulator

A high-voltage insulator and composite technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of heavy transformer, large size and weight, and achieve the effect of simple structure, reduced volume and guaranteed contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

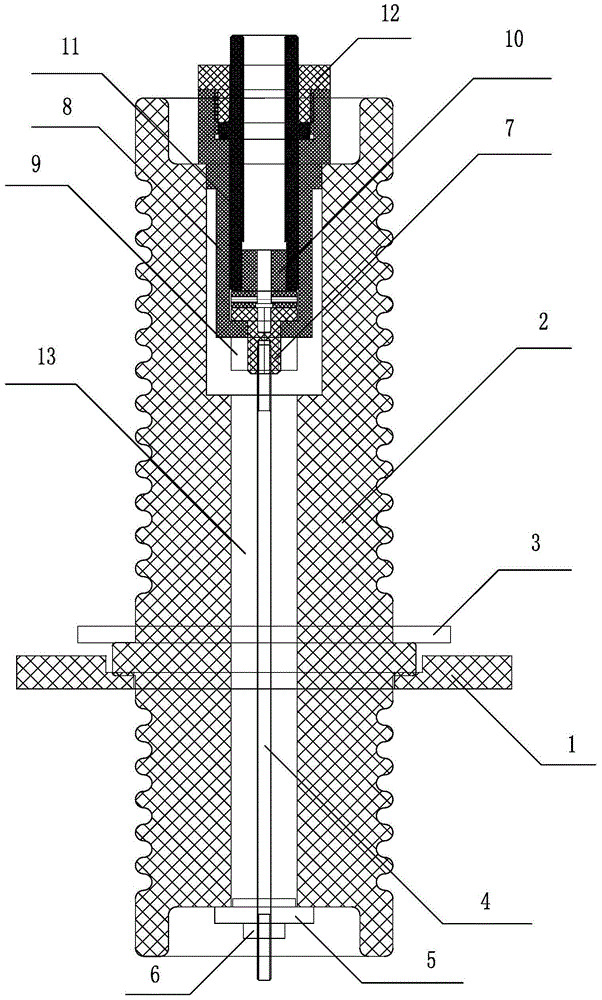

[0013] like figure 1 As shown, the present invention mainly includes an insulating flange 1, a cylinder 2, an insulating pressure plate 3, a conductive screw 4, a conductive seat 7, a conductive joint 10 and an insulating sheath 11, and the outer ring of the cylinder 2 is fixedly connected to the insulating flange 1 and the insulating The pressing plate 3 realizes the insulation and fixing of the column body 2 through the insulating flange 1 and the insulating pressing plate 3 .

[0014] The lower part of the central inner hole of the cylinder 2 is provided with a conductive screw 4 , and the lower end of the conductive screw 4 protrudes from the cylinder 2 and is connected to an insulating backing plate 5 .

[0015] There is a certain gap 13 between the conductive screw 4 and the central inner hole wall of the cylinder 2, and the gap 13 is filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com