Multifunctional organic fertilizer spreader

A technology of organic fertilizer and fertilizer spreader, which is applied to fertilizer distributors, fertilizer application devices, applications, etc., can solve the problems of affecting the growth and output of crops, high manufacturing cost, uneven spreading, etc., and achieves simple structure, convenient conversion, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

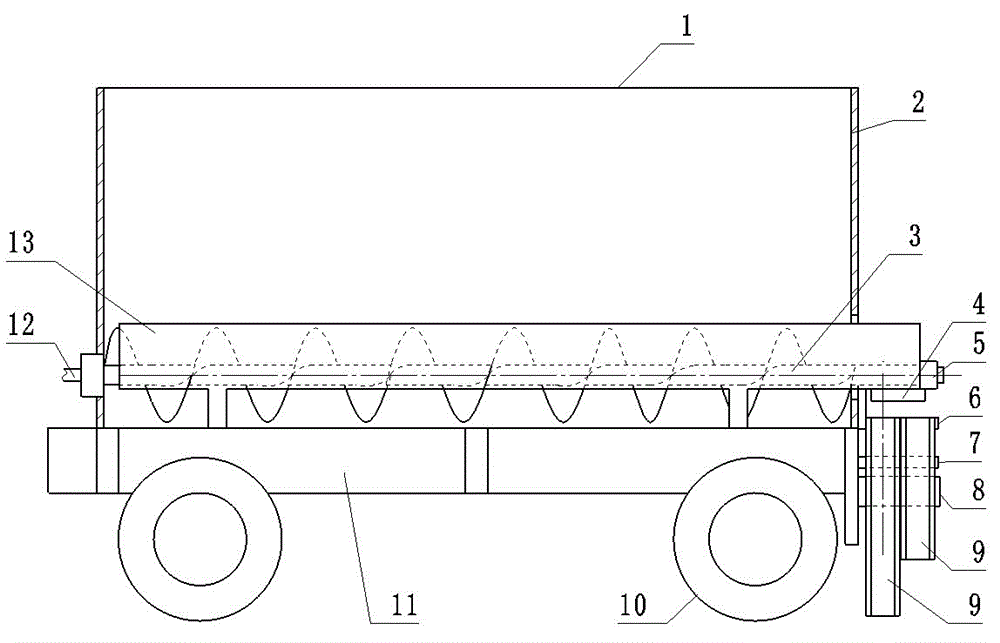

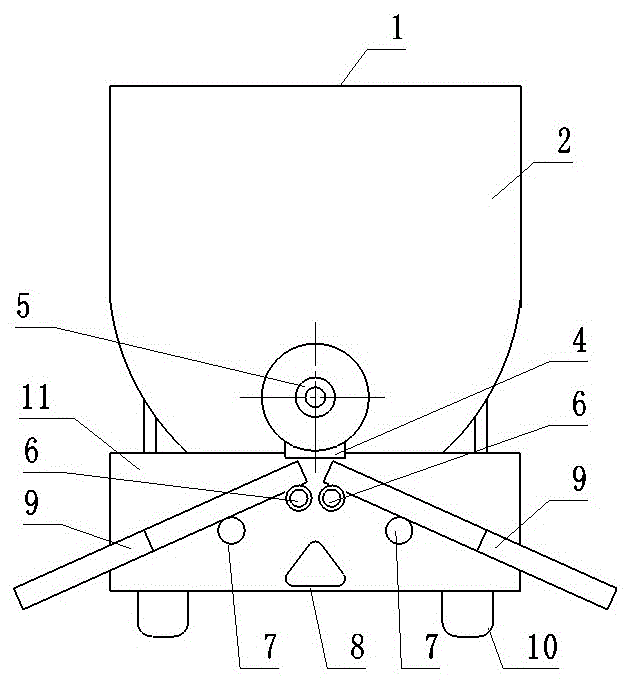

[0020] refer to figure 1 — Figure 5 , is the structure schematic diagram of the present embodiment, a kind of multifunctional organic fertilizer spreader vehicle, comprises frame 11, traveling wheel 10, does not have fertilizer box 2 on the frame 11, power input end 12, and described fertilizer box 2 is provided with The opening 1 is provided with a conveying hinge 3 near the lower part of the fertilizer box 2. The front of the conveying hinge 3 is connected to the power input end 12, and the rear of the conveying hinge 3 is connected to the bearing 5. The conveying hinge The top of the dragon 3 is provided with an arc-shaped cover plate 13, and the arc-shaped cover plate 13 protrudes backward from the fertilizer box 2 to be fixedly connected with the bearing 5, and the lower part is provided with a fertilizer dropping port 4, which communicates with the inside of the fertilizer box ; Outside the fertilizer box 2, a fertilizer slideway 9 is provided near the lower end of the...

Embodiment 2

[0022] Compared with Embodiment 1, the difference lies in that the lower section of the fertilizer box 2 is arranged in a "U" shape. The fertilizer slides 9 are symmetrically provided with multiple ones, and the lengths of the fertilizer slides 9 on one side are inconsistent.

Embodiment 3

[0024] Compared with the embodiment 2, the difference lies in that: the fertilizer box 2 is provided with a loose fertilizer pile 8 near the fertilizer falling port 4, and the loose fertilizer pile 8 is in the shape of a triangular column with the tip pointing up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com