Euphausia superba dried product production method

An Antarctic krill and production method technology, applied in the field of food processing, can solve the problems of increased fluorine content in shrimp meat and the decline of Antarctic krill quality, and achieve the effect of reducing logistics costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

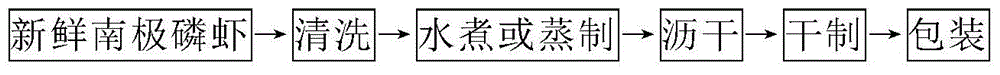

Method used

Image

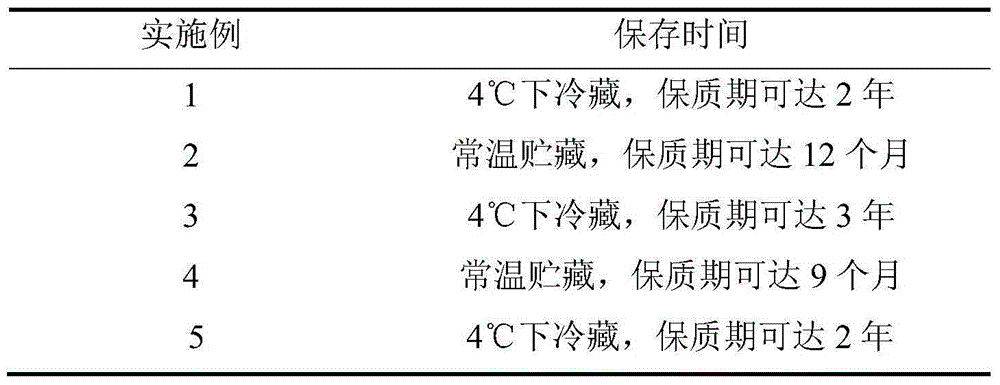

Examples

Embodiment 1

[0019] A method for producing dried Antarctic krill products carried out on board specifically includes the following steps:

[0020] (1) Pretreatment: Clean the freshly caught Antarctic krill with seawater, sort out miscellaneous fish, weeds and unqualified krill, etc., ensure that the krill damage rate is below 0.1%, and select large-sized Antarctic krill (45mm <body length), and the krill meeting this specification is more than 95%;

[0021] (2) Boil in water: put 1kg of the large-scale Antarctic krill pretreated in step (1) into a cooking pot and boil, add 0.01kg of salt, heat the water to 80°C, keep at this temperature for 15 minutes, remove it, and Drain the Antarctic krill;

[0022] (3) drying: adopt 60 ℃ of hot air to dry, through about 1 hour, make the water weight content in Antarctic krill be reduced to 18-20%;

[0023] (4) Packaging: the dried Antarctic krill products are usually sealed and packaged.

Embodiment 2

[0025] The production method of the Antarctic krill dried product that the present invention carries out on board specifically comprises the following steps:

[0026] (1) Pretreatment: Clean the freshly caught Antarctic krill with seawater, sort out miscellaneous fish, weeds and unqualified krill, etc., ensure that the krill damage rate is below 0.1%, and select medium-sized Antarctic krill (35 < body length ≤ 45mm), so that more than 95% of krill meet this specification;

[0027] (2) Steaming: Put 1 kg of medium-size Antarctic krill pretreated in step (1) into a cooking pot for boiling water steaming, and after steaming for 3 minutes, take out the Antarctic krill and drain;

[0028] (3) drying: adopt 50 ℃ of hot air to dry, after about 2 hours, make the moisture weight content in Antarctic krill be reduced to 18-20%;

[0029] (4) Packaging: Vacuum-seal the dried Antarctic krill products.

Embodiment 3

[0031] The production method of the Antarctic krill dried product that the present invention carries out on board specifically comprises the following steps:

[0032] (1) Antarctic krill pretreatment: Wash freshly caught Antarctic krill with seawater, sort out miscellaneous fish, weeds and unqualified krill, etc., to ensure that the krill damage rate is below 0.1%, and select medium-sized Antarctic krill Shrimp (35 < body length ≤ 45mm), so that more than 95% of krill meet this specification;

[0033] (2) Boil in water: put 1 kg of medium-sized Antarctic krill pretreated in step 1 into a cooking pot for boiling, add 0.02 kg of salt, heat the water to 95°C, keep it at this temperature for 1 minute, and remove it. Antarctic krill drained;

[0034] (3) Drying: adopt the sun to dry, and after about 10 hours, the water weight content of Antarctic krill is reduced to 18-20%;

[0035] (4) Packing: vacuum pack the dried Antarctic krill products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com