Thermal insulation and heating system and method of crushing motor cone liner before pre-installation

A heating system and liner technology, applied in grain processing, etc., can solve the problems of no heat preservation measures, slow conduction speed, resin loss of moving cone liner, etc., achieve automation of heating process, avoid temperature loss, and easy installation and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

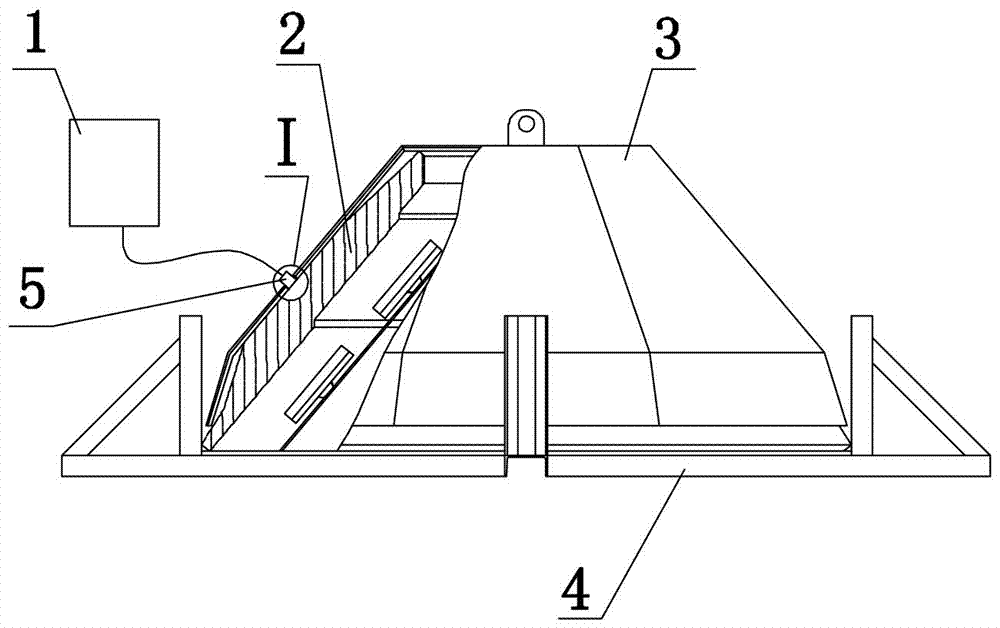

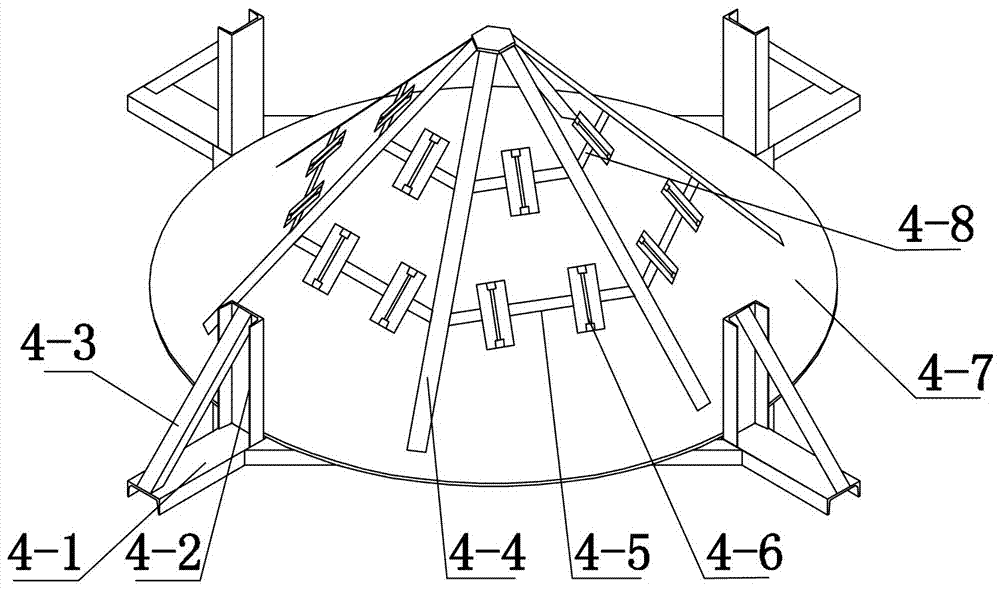

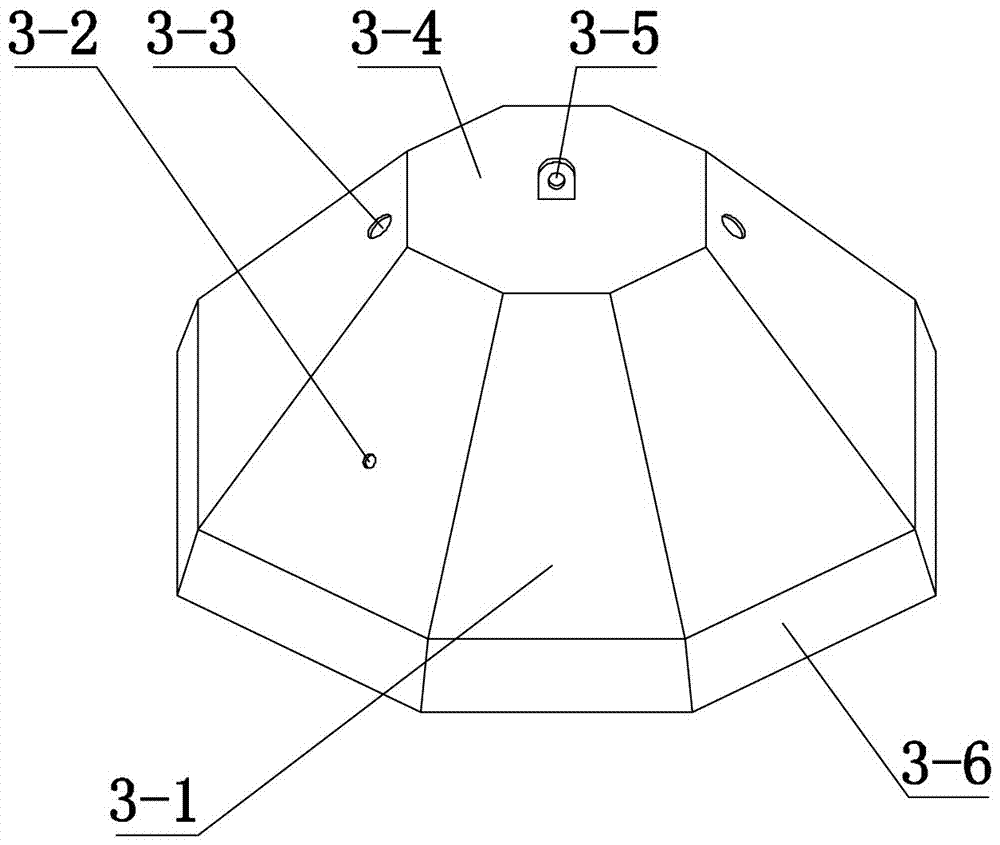

[0033] Such as figure 1 , 3 As shown, the heat preservation and heating system of the crushing motor cone liner before pre-installation of the present invention is characterized in that: it includes an insulation cover arranged on the outer surface of the cone-shaped liner 2 on the crushing motor cone, attached to the cone-shaped A temperature sensor 5 on the outer surface of the lining plate 2, a heating device 4 arranged under the heat preservation cover and a temperature control box 1 connected to the temperature sensor 5 through a data line, and a heat preservation cover is provided with a The sensor installation hole 3-2 and two symmetrical resin injection holes 3-3, the sensor installation hole 3-2 and the resin injection hole 3-3 should be arranged in a staggered manner, symmetrical on the top of the cone liner of the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com