Steel ladle compounding building technology

A technology of ladle and technology, applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve problems such as safety accidents, and achieve the effect of improving the use of heat, quality change, and improving masonry work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

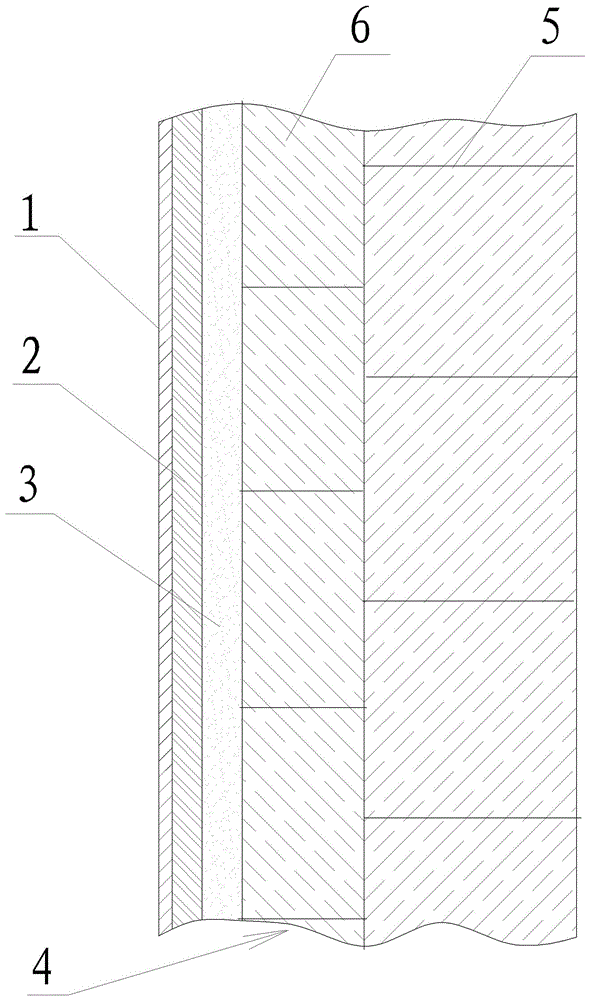

[0027] The ladle composite masonry technology includes an insulation layer 2, a permanent working layer 3, and a consumable working layer 4, which are sequentially built from the ladle steel shell 1 inward. The described consumption working layer 4 is changed from a traditional one-layer working layer to an inner layer working layer 6 and an outer layer working layer 5 by composite masonry. The inner layer brick of the inner layer working layer 6 and the outer layer working layer 5 When the outer layer of bricks is compositely built, the horizontal and vertical joints should be staggered. Its composite masonry technology includes the following steps:

[0028] Step 1. Preparation of masonry materials. Before masonry, prepare the materials required for masonry, such as joint materials, knotting materials, insulation boards, nozzle seat bricks, breathable seat bricks, bottom-covering and wall-covering consumption working layer bricks , Bottom-covering and wall-covering permanent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com