Alternating current-direct current electric locomotive traction device and system

A technology for traction devices and electric locomotives, applied in electric traction, electric vehicles, vehicle components, etc., can solve the problem of not being able to greatly improve the power factor and harmonic components of a single-phase half-controlled bridge phase-controlled rectifier circuit, increasing cost investment and maintenance. Strength, low reliability of power compensation devices, etc., to achieve the effect of simple structure, excellent power quality, and suppression of high-order harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

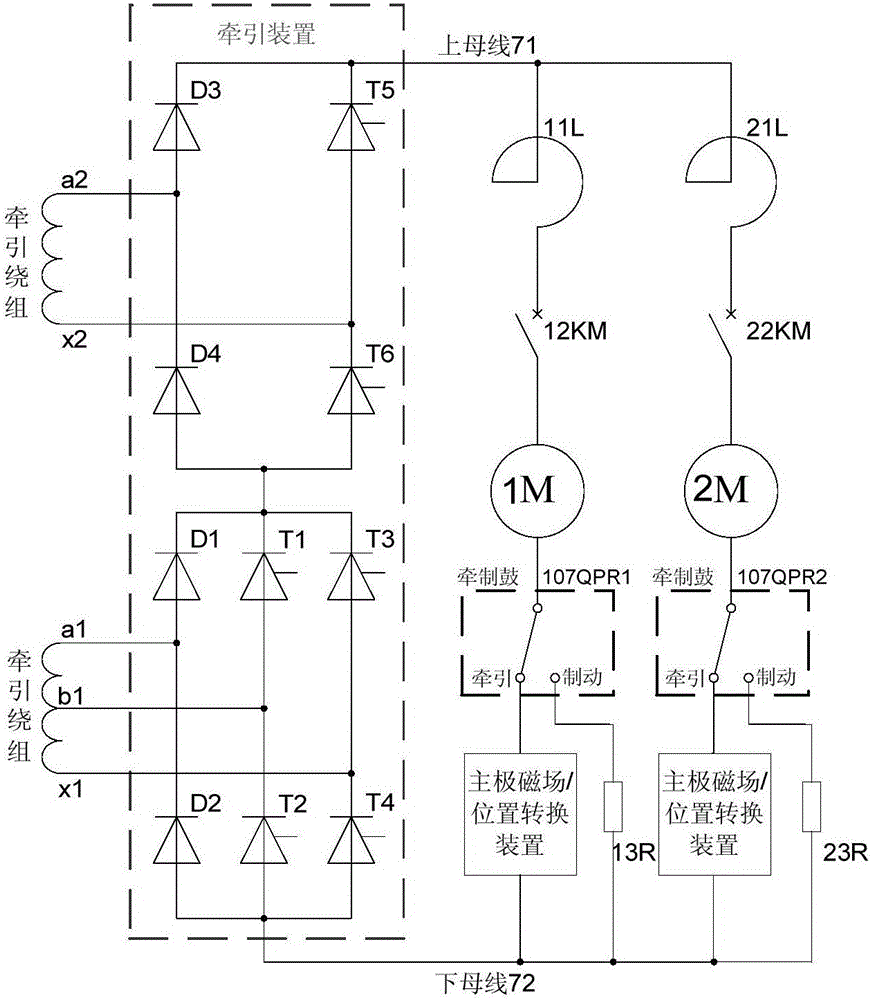

[0040] Such as Figure 4 As shown, the AC / DC electric locomotive traction device of this embodiment includes a PWM converter unit and a step-down chopper unit. The input end of the PWM converter unit is connected to the power grid, and the output end is connected to the traction motor through the step-down chopper unit; The unit converts and stabilizes the AC power of the connected grid, and outputs DC; the step-down chopper unit steps down and chops the DC output from the PWM converter unit into the required DC by controlling the on and off of the chopper switch tube, and supplied to the traction motor.

[0041] In this embodiment, the AC voltage of the AC-DC electric locomotive transformer is converted into DC voltage by the PWM converter unit, which can real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com