Temporary fixing device and construction method thereof

A technology of temporary fixation and construction method, applied in transportation and packaging, ship parts, ships, etc., can solve the problem of welding the main hull as a whole, and achieve the effects of high structural safety and reliability, low cost, and simple offshore construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

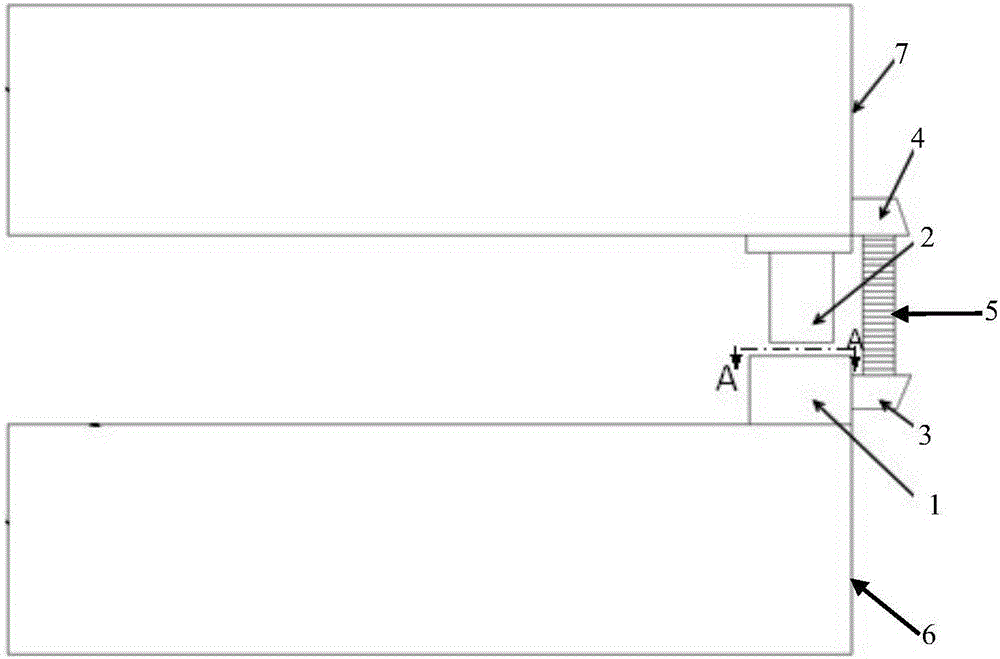

[0022] figure 1 is the front view of the temporary fixing device in the embodiment of the present invention.

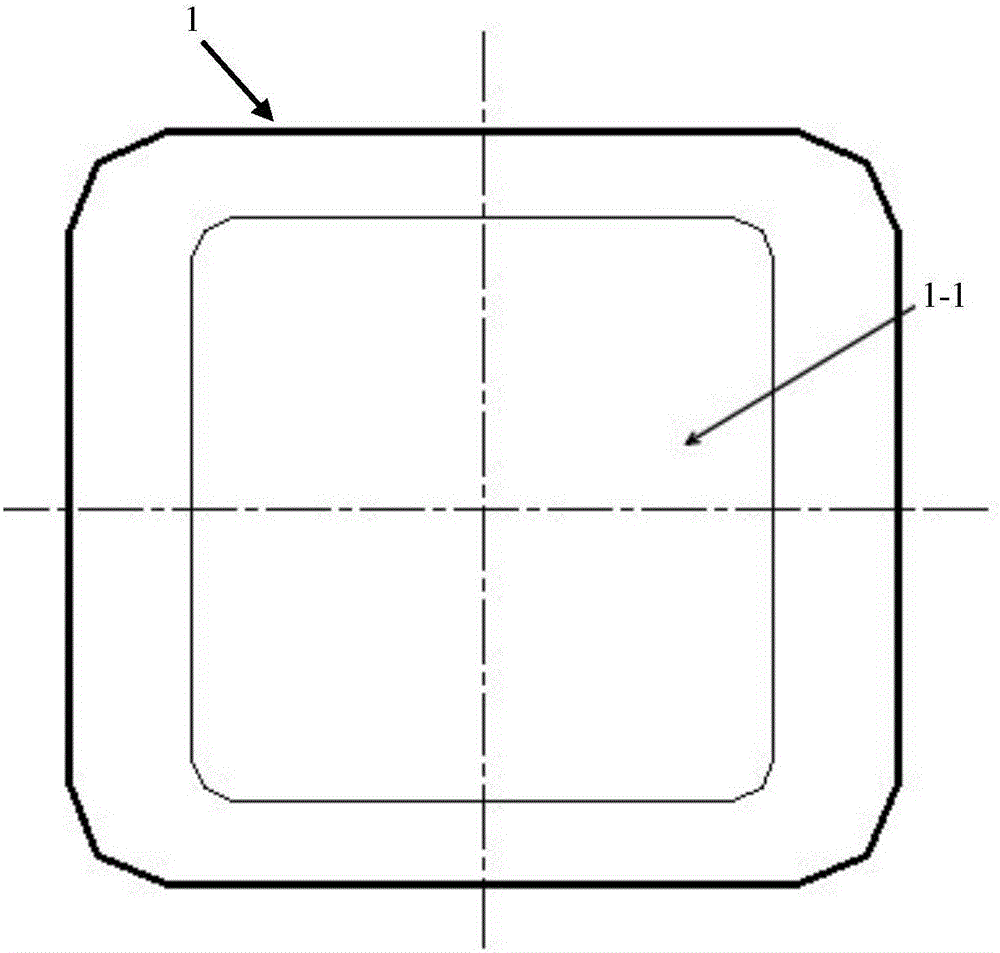

[0023] figure 2 It is a top view of the A-A section of the present invention in an embodiment.

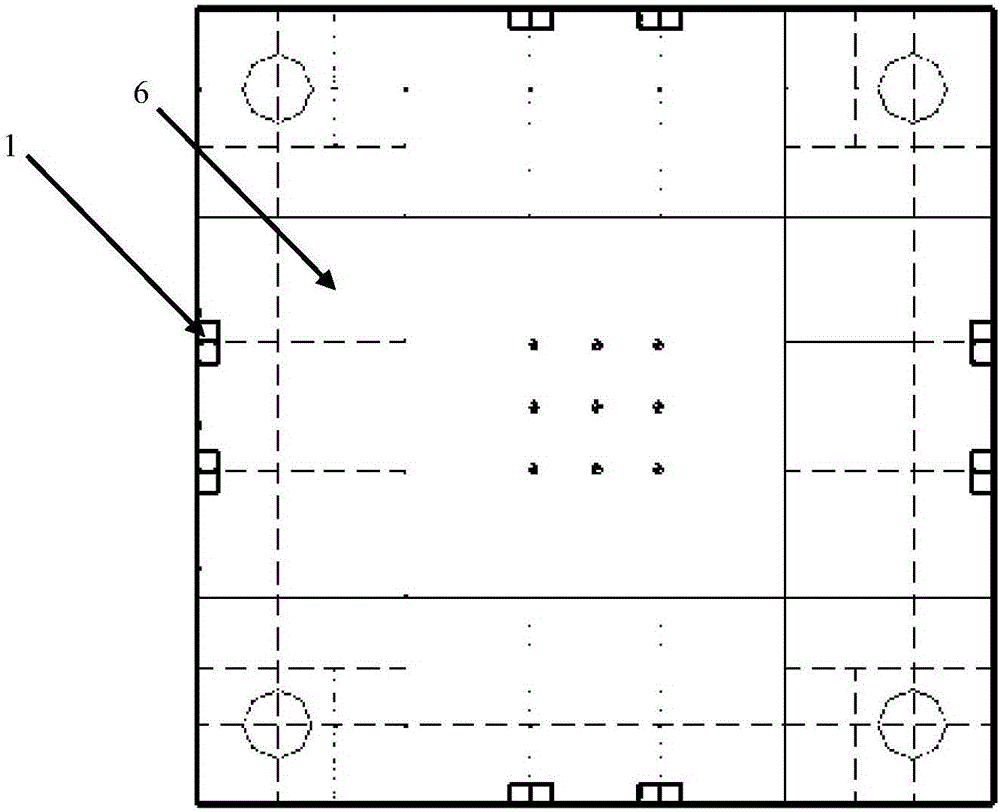

[0024] image 3 It is a schematic diagram of the arrangement of the base structure of the present invention on the roof deck of the lower pontoon in the embodiment.

[0025] like figure 1 , figure 2 and image 3 As shown, the temporary fixing device has: a base structure 1 , a latch structure 2 , a lower internally threaded member 3 , an upper internally threaded member 4 and a stud 5 .

[0026] The temporary fixing device is used between the upper buoyancy tank 7 and the lower buoyancy tank 6 in the wet towing transportation of the new semi-submersible oil production platform.

[0027] Several base structures 1 have openings 1-1 in the center respectively. The base structure 1 is arranged at the outer edge of the top deck of the lower pontoon tank 6, and is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com