Automatic lifting and transferring machine for painted flat plate jig

An automatic lifting and transfer machine technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of material cost waste, increased labor costs, high work intensity, etc., to reduce the risk of fixture damage and improve The effect of improving the level of automation and the flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiments.

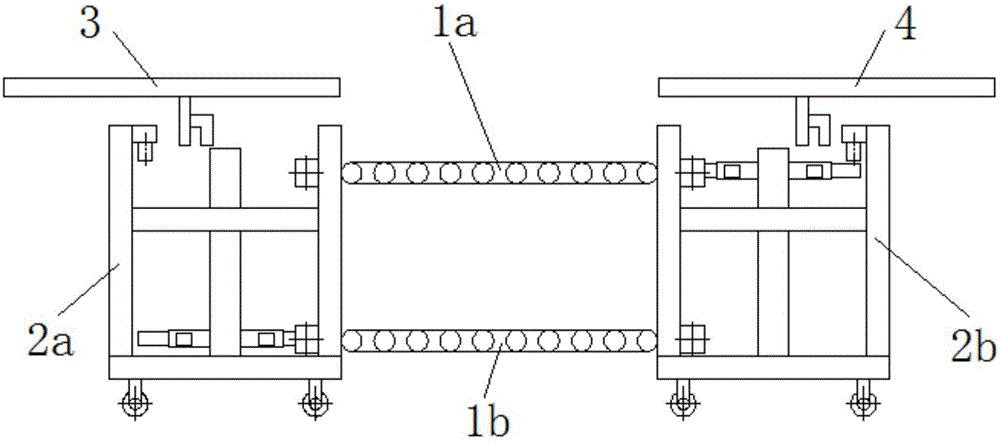

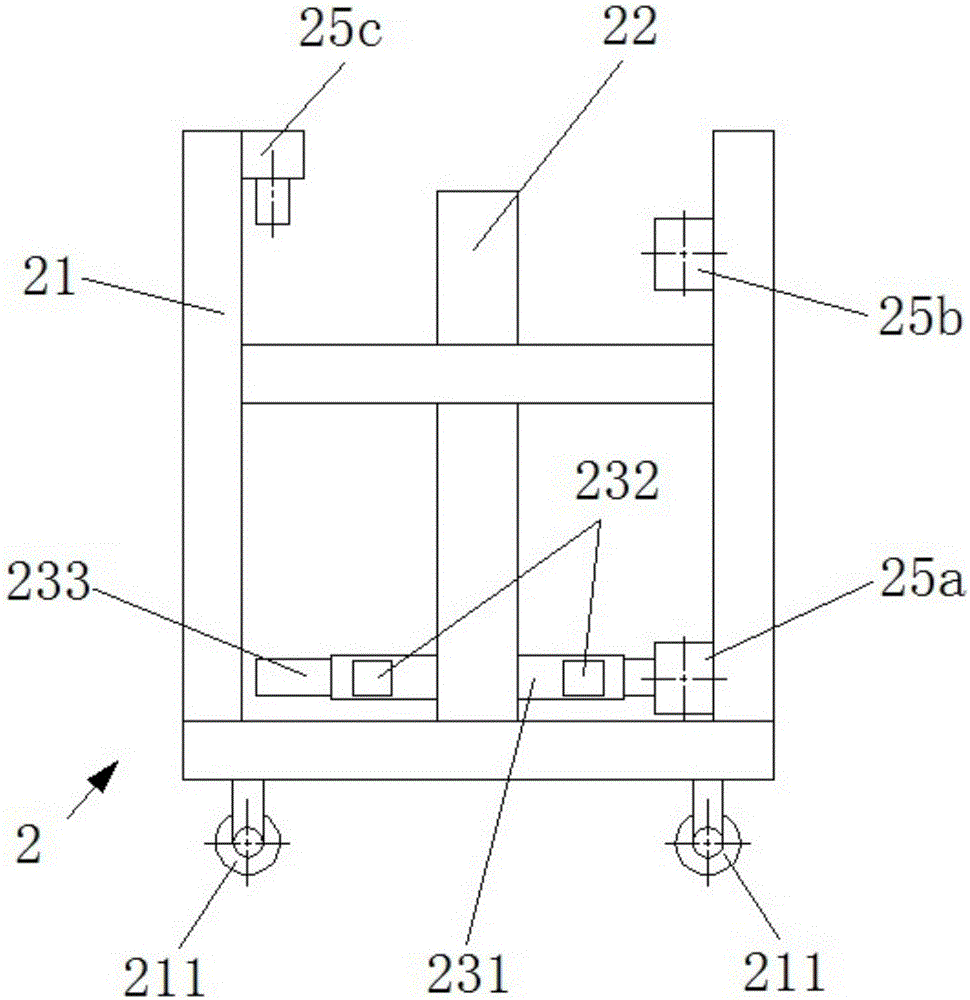

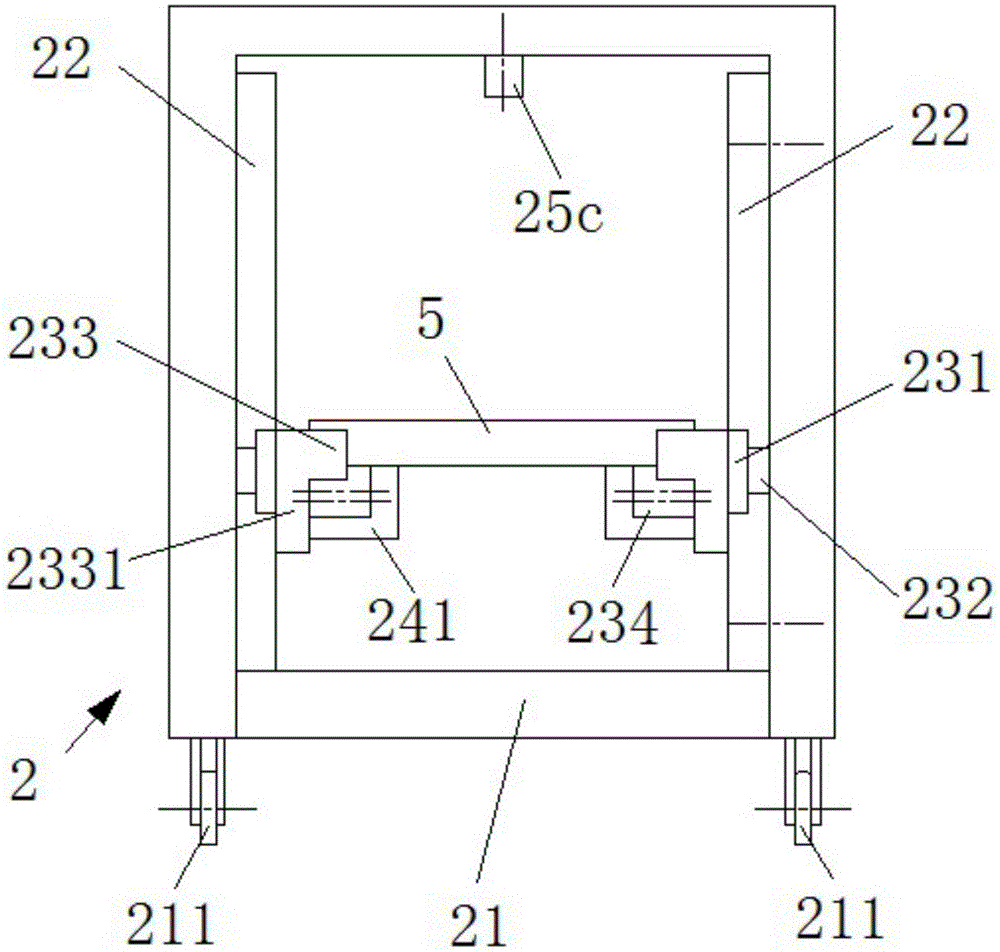

[0030] Such as figure 1 , figure 2 with Figure 5 As shown, an automatic lifting transfer machine for coating flat fixtures of the present invention includes two conveyor belts (first conveyor belt 1a, second conveyor belt 1b) arranged in parallel up and down, two conveyor belts (1a, 1b) A pair of lifting mechanism 2 (the first lifting mechanism 2a, the second lifting mechanism 2b) on the side, the discharging mechanism 3 located at the top of the first lifting mechanism 2a and the reclaiming mechanism 4 located at the top of the second lifting mechanism 2b, lift The mechanism 2 includes a frame 21, a pair of lifting modules 22 vertically arranged on the frame 21, and a material clamping unit 23 controlled by the lifting module 22. The material clamping unit 23 is provided with a material transfer motor 24, and the first conveyor belt 1a and The second conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com