Application method of vacuum sputtering coated substrate clamping device

A vacuum sputtering and clamping device technology, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problems of difficult substrate clamping, complex structure, high efficiency, etc., and achieves easy processing, Strong versatility and the effect of solving diffraction problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

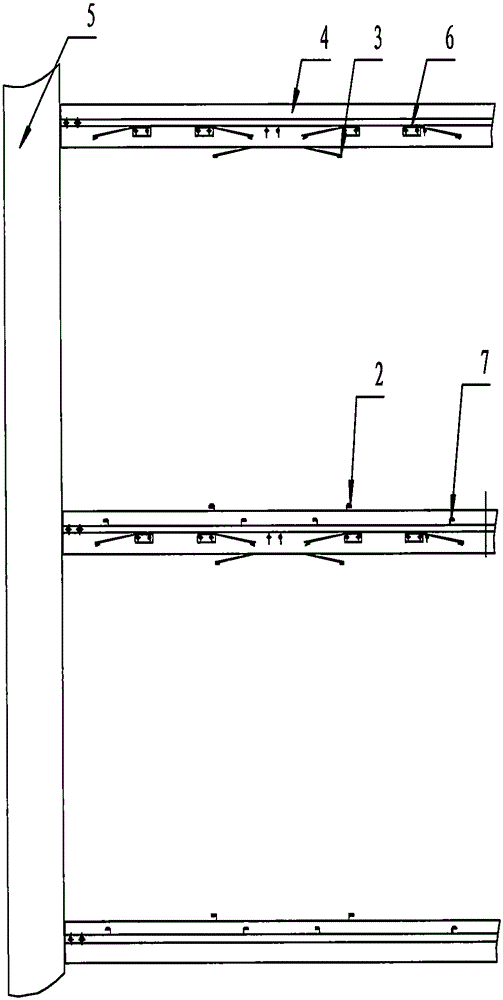

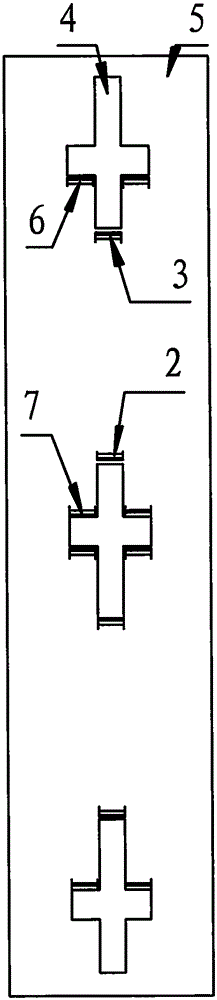

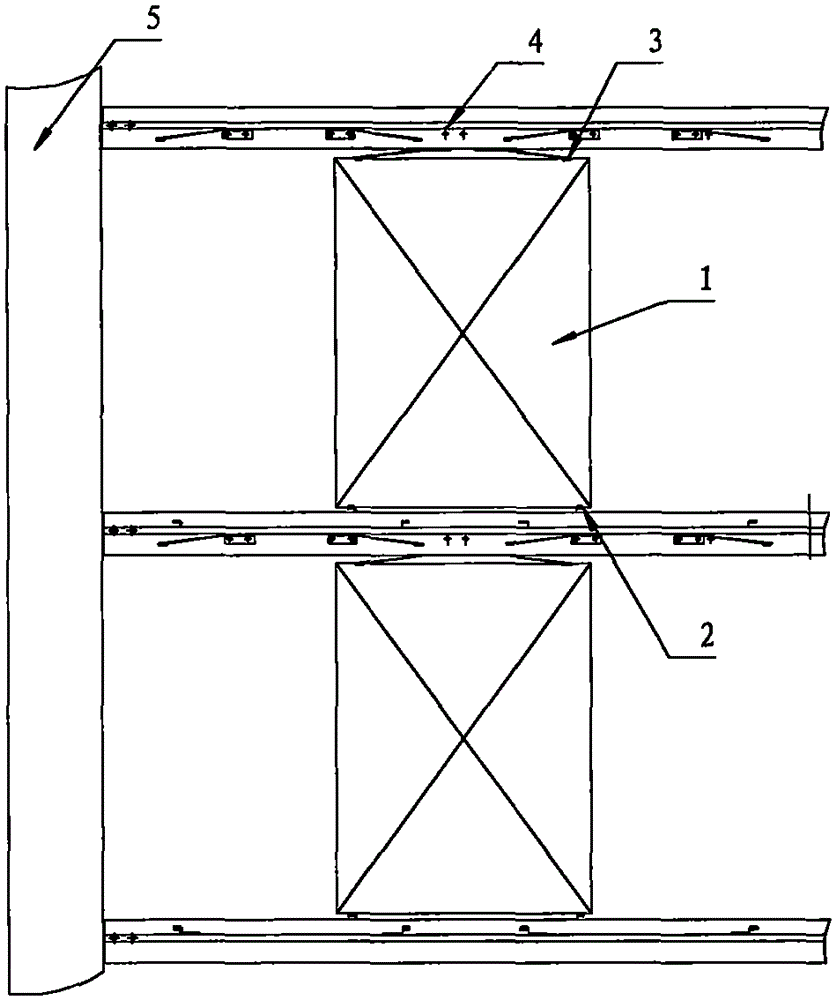

[0018] At least two cross beams 4 are arranged on one side of the vertical beam 5, and the cross beam 4 is set in a cross shape, and side beams are respectively arranged on both sides of the cross beam 4; two double-sided lower elastic cards 2 are arranged symmetrically on the upper side of the middle cross beam 4, and the lower side of the upper cross beam 4 is symmetrical Set two double-sided elastic cards 3, the double-sided elastic card 3 and the double-sided lower elastic card 2 are set correspondingly, and the double-sided substrate 1 is arranged between the double-sided lower elastic card 2 and the double-sided elastic card 3 A group of double-sided elastic cards 3 and double-sided lower elastic cards 2 are arranged under the upper beam 4 and on the middle beam 4; two single-sided elastic cards 6 and the sides of the middle beam 4 are arranged symmetrically under the side beams of the upper beam 4. Two single-sided lower elastic clips 7 are arranged symmetrically on the ...

Embodiment 2

[0021] The single-sided substrate 8 is clamped by the elastic clips 6 on one side and the lower elastic clips 7 on one side, and is fixed between the upper and lower beams 4 on one side of the beam 4; the transport trolley is started, and the transport trolley drives the vertical beam 5 and The beam 4 and the single-sided substrate 8 enter the vacuum sputtering coating box, and the single-sided substrate 8 is sputtered and coated on one side.

Embodiment 3

[0023] When processing vacuum sputtering coating on double-sided substrate 1, first put the lower side of double-sided substrate 1 into the slot of double-sided lower elastic card 2 of lower beam 4, and the lower side of double-sided substrate 1 is composed of two double-sided The lower elastic card 2 is symmetrically supported, and then the card slot of the elastic card 3 on both sides of the upper beam 4 is clamped on the upper side of the double-sided substrate 1, and the upper side of the double-sided substrate 1 is supplemented by two symmetrical elastic cards 3 on both sides. tight; the double-sided substrate 1 is clamped by the double-sided elastic clamp 3 and the double-sided lower elastic clamp 2, and is fixed between the upper and lower beams 4 on one side of the beam 4; the conveying trolley is started, and the vertical beam is driven by the conveying trolley 5 and the beam 4 and the double-sided substrate 1 enter the vacuum sputtering coating box, and the double-sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com