Underground powerhouse wire outgoing arrangement mode and structure

A technology of outgoing line layout and underground workshop, applied in water conservancy projects, hydroelectric power stations, industrial buildings, etc., can solve the problems of large project investment, unreasonable layout of underground workshops, and insufficient underground transportation, so as to achieve convenient and economical investment. Significant benefits and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

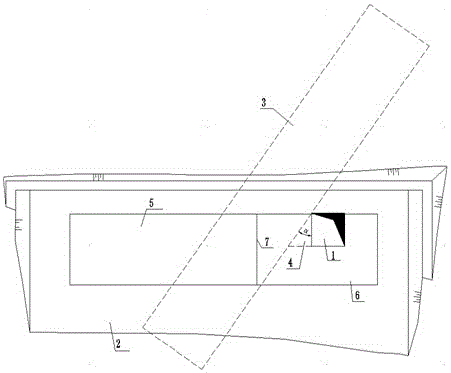

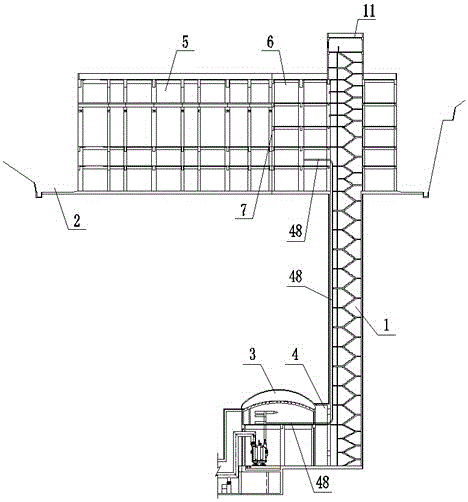

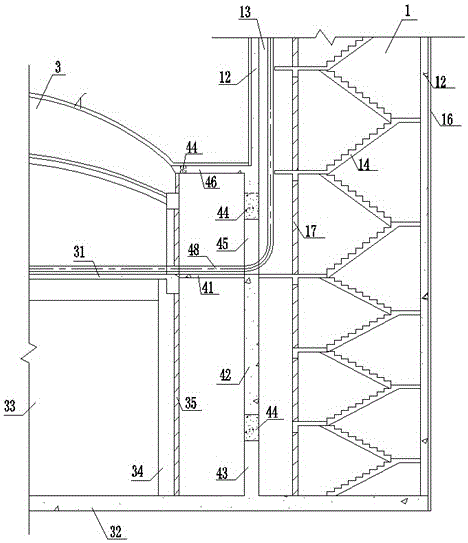

[0024] Take the underground powerhouse of a hydropower station in Guizhou as an example (such as Figure 1-Figure 7 Shown): The underground powerhouse caverns are arranged in the mountain on the left bank of the dam. The main powerhouse and the main transformer tunnel 3 are arranged in parallel. The longitudinal axis of the powerhouse is N79oE, and the main transformer is arranged in the underground main transformer tunnel 3 , the excavation section of the main transformer tunnel 3 has a dimension of 83.4m×15.3m×16.2m (length×width×height), and the 220kV switch station 2 is arranged on the ground at an elevation of 605.0m above the main transformer tunnel 3, with a plane size of 80m×28m. The main transformer is connected to the 220kV bottom switch station 2 through the triangular prism excavation body 4 and the outlet shaft 1 with a 220kV dry-type high-voltage cable 48 .

[0025] Such as image 3 As shown, the height of triangular prism excavation body 4 is 13.07m, and the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com