Method and device for quickening water filling and pressure relief of plane gate

A flat gate, horizontal pressure technology, applied in water conservancy projects, hydropower, hydropower stations, etc., can solve problems such as imperfection, large gate slot size, increased main beam height, etc., to reduce maintenance time, reduce The effect of local deformation and instability, and speeding up the water filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

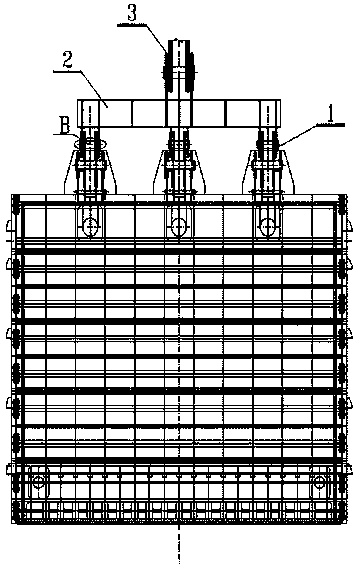

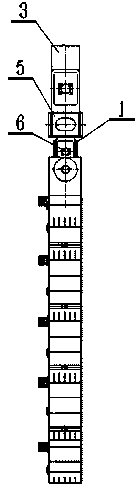

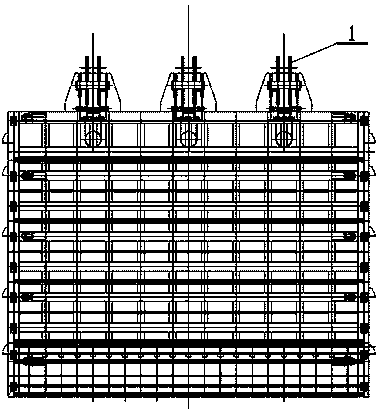

[0043] A structural schematic diagram of a device for accelerating the filling and hydraulic pressure of the plane gate of the present invention is as follows: Figure 1-9 As shown, three gate water filling valves 1 are arranged on the top of the gate, and a balance hanging beam device 2 is arranged on the upper part of the gate water filling valve 1. The upper part of the balance hanging beam device 2 is connected with the head 3 of the hoist. The lower part of the beam device 2 is connected with the water filling valve 1 of the gate.

[0044] see Figure 8 A downwardly inclined water filling valve pipe 4 is arranged at the corresponding position of the gate and the lower part of the gate water filling valve 1. The angle between the axis of the water filling valve pipe 4 inclined downward and the horizontal line is 20°. Therefore, when the gate is filled with water , can reduce the damping of water flow, speed up the flow rate of water, and increase the water filling speed. ...

Embodiment 2

[0054] A structural schematic diagram of an accelerated planar gate filling hydraulic device of the present invention is as follows: Figures 14-19 As shown, five gate water filling valves 1 are arranged on the top of the gate, and a balance hanging beam device 2 is arranged on the upper part of the gate water filling valve 1. The lower part of the beam device 2 is connected with the water filling valve 1 of the gate.

[0055] see Figure 8 A downwardly inclined water filling valve pipe 4 is installed at the corresponding position of the gate and the lower part of the gate water filling valve 1. The angle between the axis of the water filling valve pipe 4 inclined downward and the horizontal line is 45°. Therefore, when the gate is filled with water, The damping of the water flow can be reduced, the flow velocity of the water can be accelerated, and the water filling speed can be improved.

[0056] see Figure 15 , The balance suspension beam device 2 is made up of 1 balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com