A post-adjustable sub-orifice composite anti-hammer air valve group

An air valve and composite technology, applied in multi-way valves, balance valves, valve devices, etc., can solve problems such as large-diameter high-speed exhaust holes, corrosion of pipe walls, and single exhaust holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

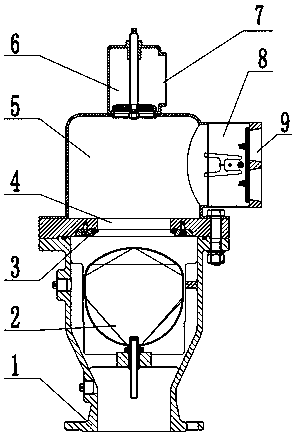

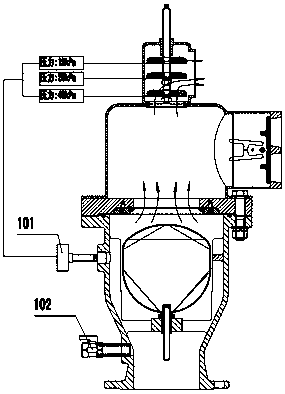

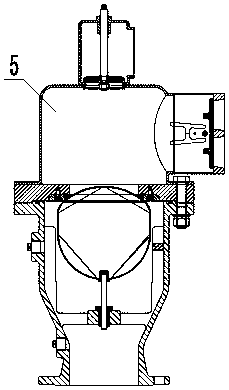

[0045] Embodiment one: if Figure 2a , 2b, 2c, when the system empty pipe is filled with liquid, the liquid column pushes the air in the pipe (system) to be discharged from the high-speed exhaust port of the air valve, the high-speed two-way intake and exhaust port 4 is open, and the second high-speed exhaust port 7 is also in the fully open position in the initial state. Observe the pointer of the pressure gauge 101 on the valve body. There is a water discharge port 102 on the side wall of the valve body 1. If it is found that the orifice pressure difference (that is, the pressure gauge reading) is lower than 30~35kPa, you can properly adjust the exhaust orifice regulating valve. Make it gradually increase, the increased orifice pressure difference is also the back pressure of the liquid column flow in the pipe (system), the greater the back pressure, the slower the liquid column flow, the appropriate liquid such as V=0.3m / s The flow velocity is the most ideal empty pipe wa...

Embodiment 2

[0046] Embodiment two: if Figure 2a , 2b , 2c, when suddenly stopping the pump or closing the valve or draining water (liquid), the liquid column at some positions in the pipe (system) may separate, and a vacuum (negative pressure) appears in the system. At this time, the external pressure is greater than The internal pressure and the external air pressure push the disc of the check valve, and together with the self-weight of the disc, press down the float disc of the main valve, the disc moves down, the suction port and the two-way intake and exhaust ports are opened, and the air passes through The second high-speed suction orifice and the first two-way orifice of the negative pressure suction valve enter quickly to minimize the negative pressure in the pipe to ensure the safety of pipe fittings and sealing interfaces.

Embodiment 3

[0047] Embodiment three: as Figure 2a , 2b , 2c, when the system pressure rises to close to atmospheric pressure but is still in the state of slight negative pressure (-0.1kPa~-5kPa), the spring force of the check valve in the suction orifice or the swing check valve The gravity of the valve disc just overcomes the resultant force of the internal and external pressure difference to close the orifice, stop a large amount of suction, and prevent high-speed exhaust. The valve only has high-speed suction capability under negative pressure but no high-speed exhaust capability under positive pressure (but because the seal is not tight, it still has a small amount of exhaust and small amount of suction after the check valve is closed), It can effectively inhale and break the vacuum, so as to meet some special requirements of the pipeline system. It is a new type of vacuum breaking and negative pressure protection equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com