A method and device for improving the sealing performance of a water filling valve for an ultra-high water head gate

A water filling valve and sealing technology, which is applied in the field of gate sealing, can solve the problems of water leakage, water filling valve closing is not tight, etc., to achieve the effect of increasing water filling speed, good limit effect, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

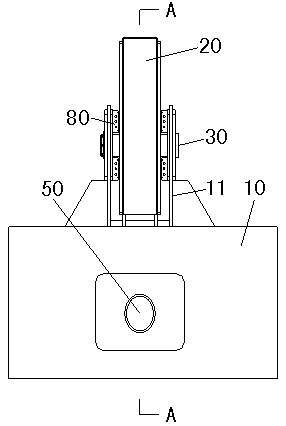

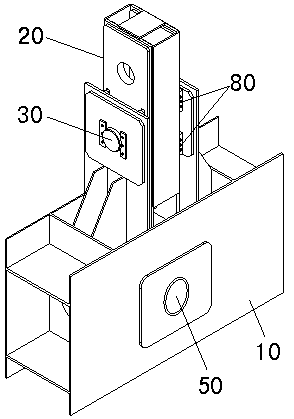

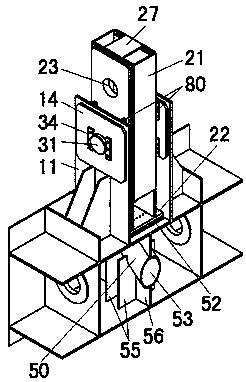

[0045] In this example, two lug plates 11 are arranged symmetrically on the top of the gate assembly 10 , a valve body assembly 20 is provided between the two lug plates 11 , and an elbow assembly 50 is provided directly below the valve body assembly 20 . The valve body assembly 20 is connected to the lug plate 11 through the suspension shaft assembly 30 and the limit shaft assembly 40; the two sides of the lug plate 11 are connected with the gate bearing plate 14; the gate bearing plate 14 is symmetrically welded to the two sides of the lug plate 11, The gate bearing plate 14 is circular or rectangular, the four corners of the rectangle are chamfered, and the gate bearing plate 14 is provided with hanging holes 23 corresponding to the lug plate 11;

[0046] The aforementioned valve body assembly 20 includes a valve column 21. The valve column 21 is a rectangular tube surrounded by four steel plates, and a positioning plate 27 is welded on the top; A shaft hole 25, and a lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com