Worm and worm gear transmission device

A transmission device, worm gear technology, applied in transmission device parts, transmission box, gear lubrication/cooling, etc., can solve the problem of high work efficiency, achieve high work efficiency, simple structure, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

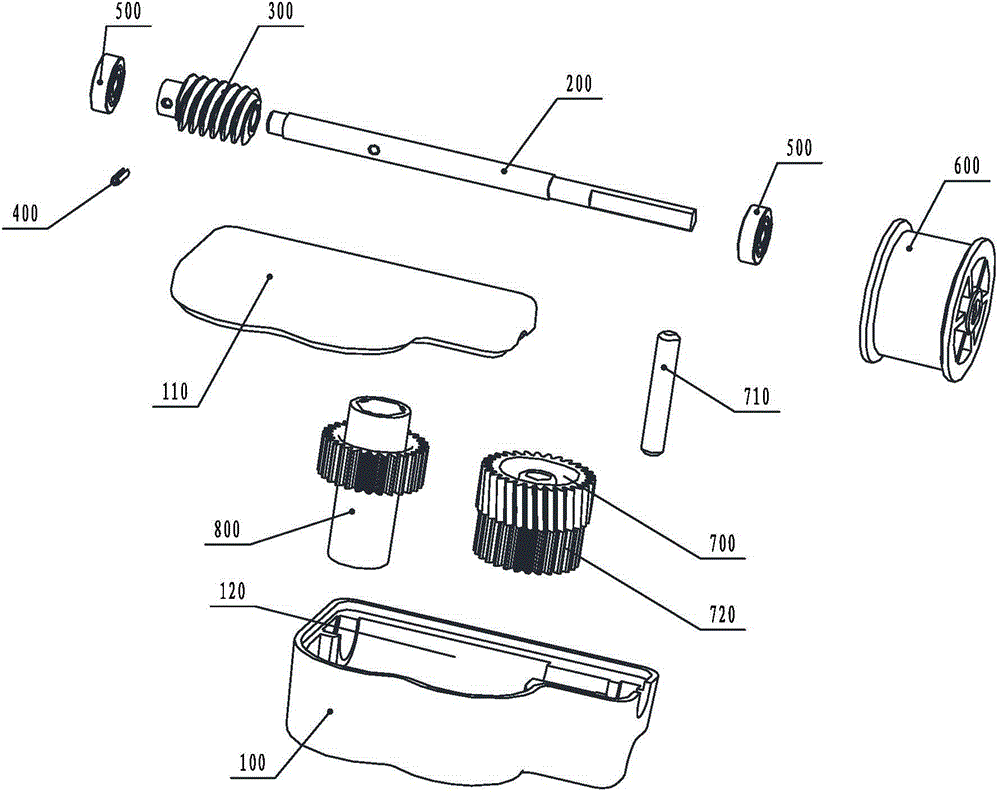

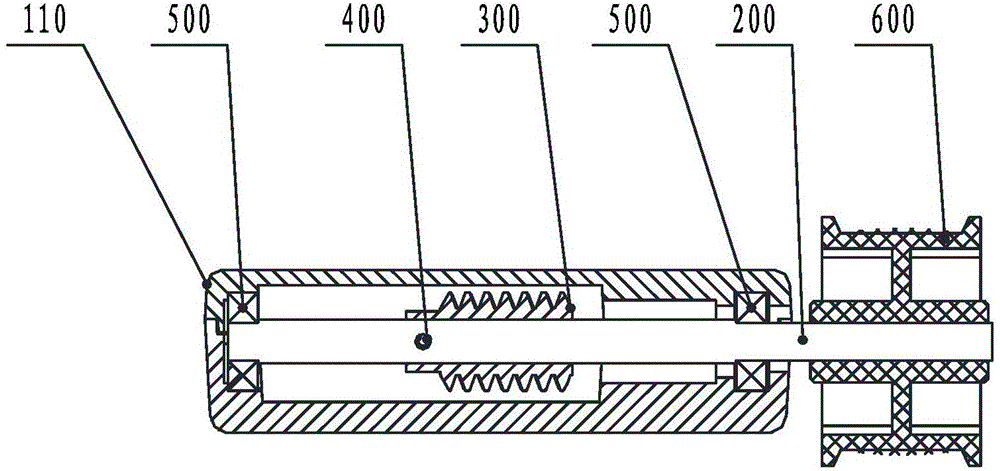

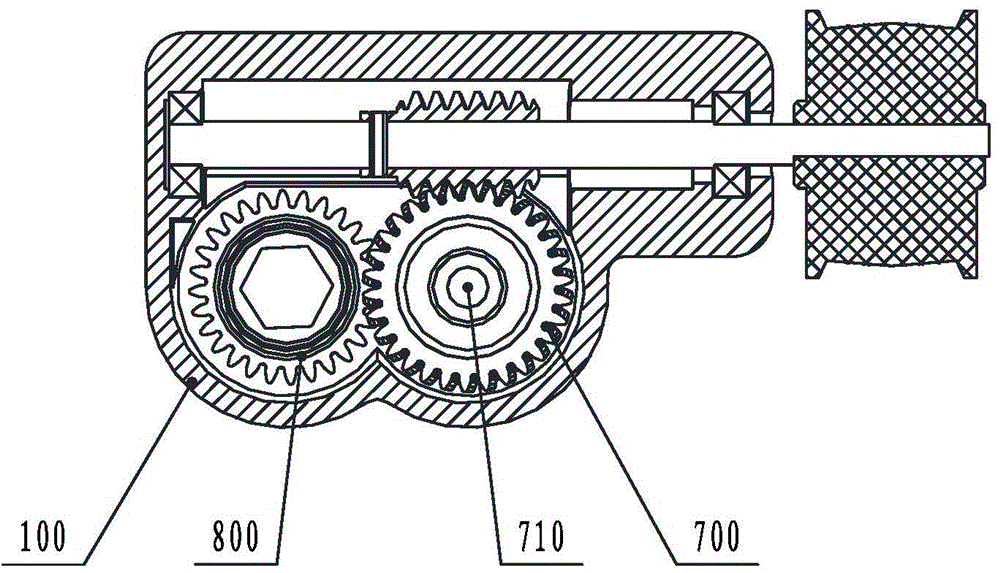

[0028] Figure 4 It is an explosion diagram of the present invention; Figure 5 It is a sectional view of the present invention; Image 6 for Figure 5 top view of Image 6 to omit Figure 4 The output gear 800 in; Figure 7 for Image 6 left view of . combine Figure 4 to Figure 7 As shown, the present invention provides a worm gear transmission with a heat dissipation unit, generally speaking, it includes a casing, and a worm 300 and a worm wheel 700 that are engaged with each other are installed in the housing cavity 120 in the casing. One end of the drive shaft is connected with a first driving device, and the worm gear is connected with the output device. The accommodating cavity 120 is also provided with an impeller 900, the impeller is connected with the second driving device, and rotates under the driving of the second driving device, and the housing is provided with an air inlet 111 and an outlet. Air port 101, under the action of the rotation of the impeller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com