Integrally mounted mechanical seal device

A mechanical seal device, cartridge technology, applied in the direction of engine seal, mechanical equipment, engine components, etc., can solve the problems of affecting the service life of the mechanical seal device, large damage to the mechanical seal device, high operator requirements, etc., to achieve savings The effect of shutdown standby time, extended service life and low technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

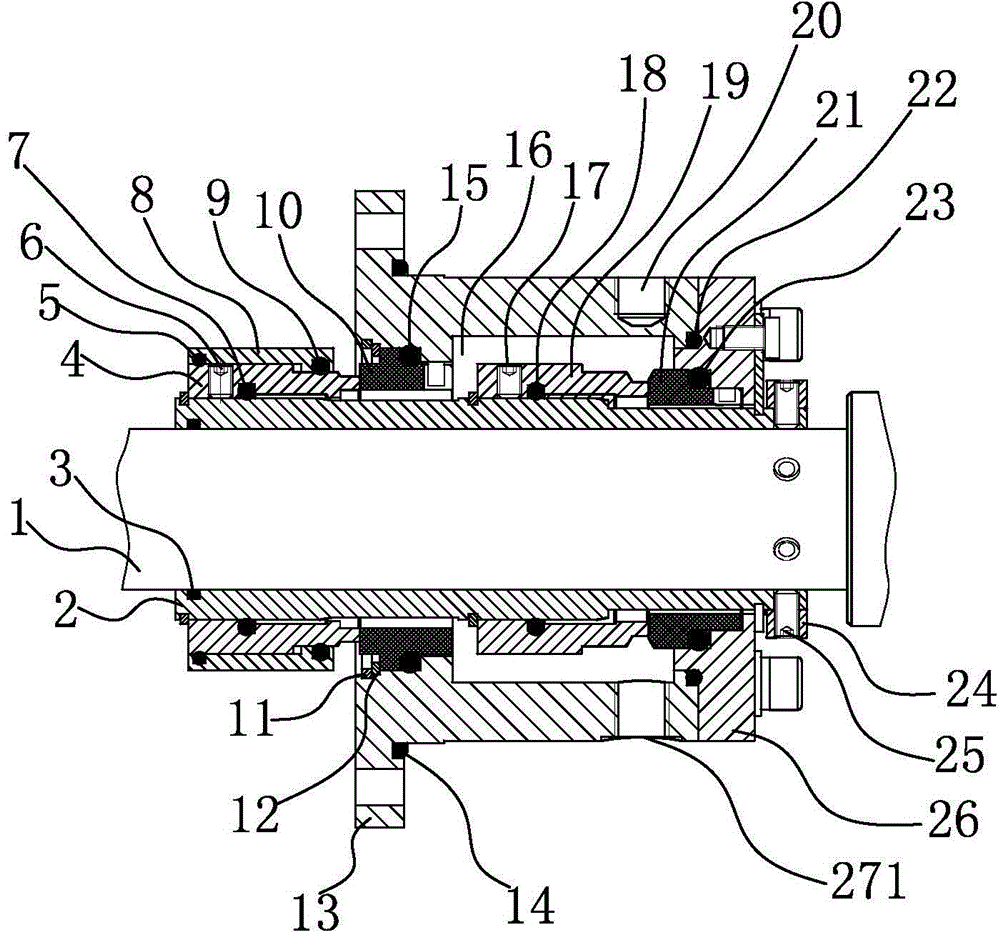

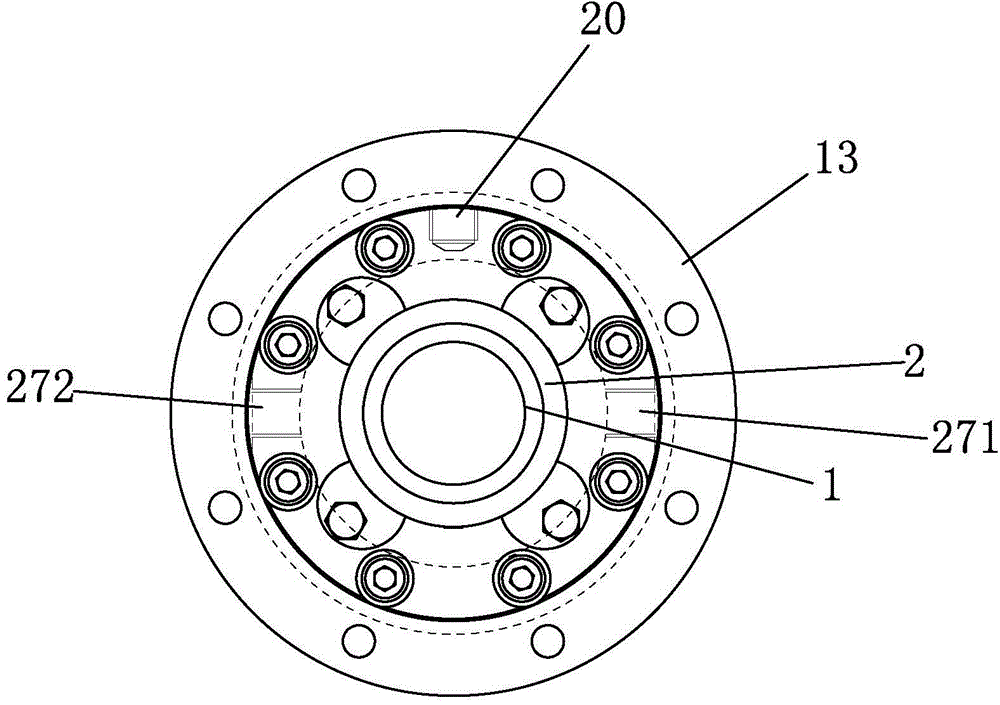

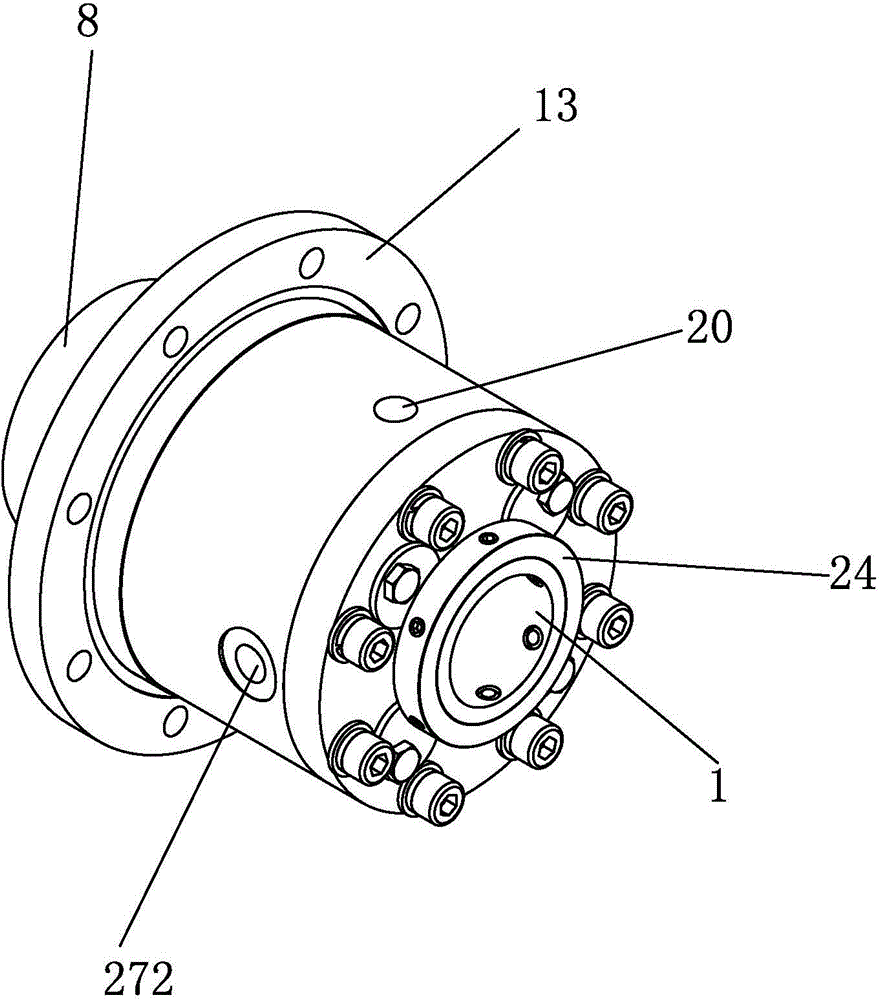

[0029] Such as Figure 1~3 As shown, the present invention discloses a cartridge mechanical seal device including a shaft sleeve 2 sleeved on a main shaft 1 of the equipment. A first sealing assembly and a second sealing assembly are sheathed on the outside of the shaft sleeve 2 in turn. The first sealing assembly includes a first moving ring 4 , and a sleeve 8 is placed around the first moving ring 4 . The second sealing assembly includes a second moving ring 19 , and the second moving ring 19 is provided with a mechanical envelope 13 . A first static ring 10 and a second static ring 21 are respectively provided at both ends of the machine envelope 13 . The end of the first moving ring 4 is attached to the end of the first stationary ring 10, the end of the second moving ring 19 is attached to the end of the second stationary ring 21, and the first stationary ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com