Direct freezing device for liquid carbon dioxide

A liquid carbon dioxide and equipment technology, applied in the field of liquid carbon dioxide direct freezing equipment, can solve problems such as low utilization rate of carbon dioxide, poor quick freezing effect, unreasonable design of freezing equipment, etc., and achieve improved CO2 utilization rate, fast freezing speed and good economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

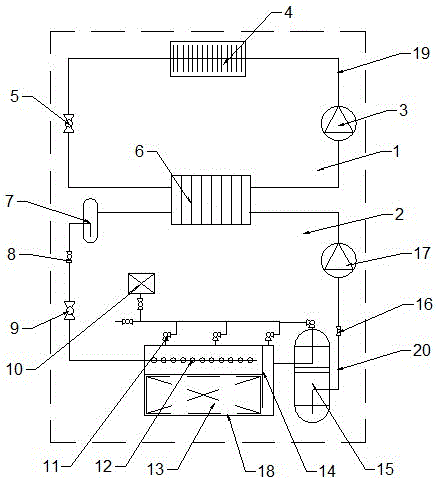

[0018] like figure 1 As shown, the present invention discloses a liquid carbon dioxide direct freezing device, which includes two high-temperature section refrigeration systems 1 and low-temperature section refrigeration systems 2 formed by cascade condensers 6 .

[0019] The high-temperature section refrigeration system 1 includes a high-temperature section compressor 3 , a high-temperature section condenser 4 , a high-temperature section throttle valve 5 and a cascade condenser 6 sequentially connected through a pipeline A19 .

[0020] The low-temperature section refrigeration system 2 includes a low-temperature section compressor 17, a cascade condenser 6, a low-temperature section storage tank 7, a cut-off valve A8, a low-temperature section throttle valve 9, a refrigeration device, a dry separator 15 and a cut-off Valve B16; a carbon dioxide direct-cooling evaporator 18 is installed inside the refrigeration device, an orifice plate 12 is arranged at the upper end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com